Introduction, Model numbers and system configurations table 1, Conditions for use – Hydrotech 12301_12302_12303 Series ADVANCED REVERSE OSMOSIS WATER TREATMENT SYSTEMS User Manual

Page 2: Options and accessories

I

INTRODUCTION

MODEL NUMBERS AND SYSTEM CONFIGURATIONS

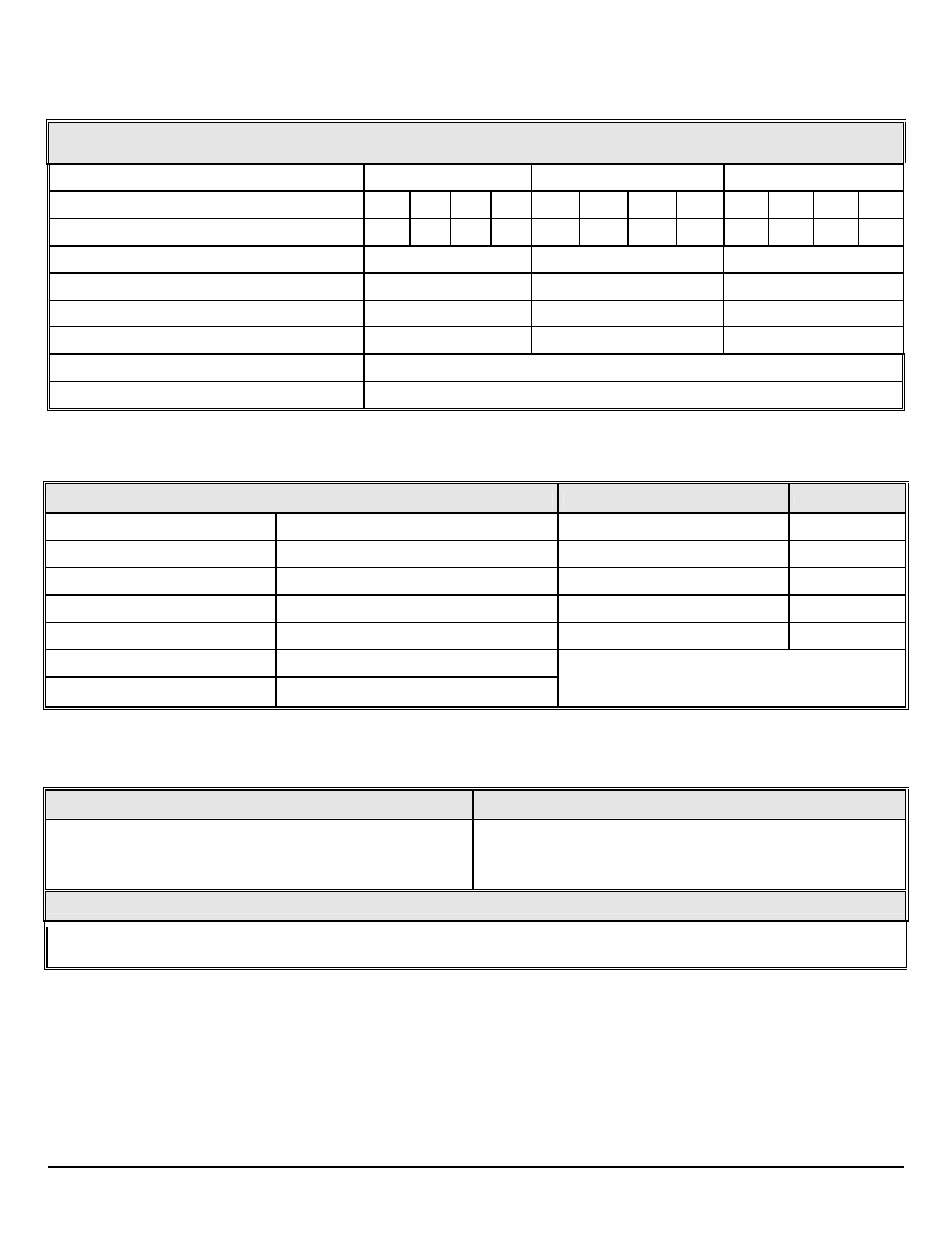

Table 1

GUIDE IS APPLICABLE TO THE REVERSE OSMOSIS DRINKING WATER TREATMENT SYSTEMS AS SPECIFIED IN THIS TABLE

Select System Code and Output Code to Determine Model Number

System Code

12301

12302

12303

Output

(GPD)*

9 25 50 75 9 25 50 75 9 25 50 75

Output

Code

03 02 01 00 00 01 02 03 00 01 02 03

Vessels 3

4

4

Monitor

None

None

Push Button Smartap

®

Sediment Filter

None

String Wound Polypropylene

String Wound Polypropylene

Pre-Filter

Dual-Purpose

Activated Carbon

Activated Carbon

Membrane

Thin Film Composite

Post Filter

Activated Carbon

* Manufacturer’s Specification with inlet conditions of 345 kPa (50 psig), 25

° C (77° F), going to atmosphere.

CONDITIONS FOR USE

THIN FILM COMPOSITE MEMBRANE

Source Water Supply Profile

Chemical Parameters

Max mg/L

Community/Private

Chlorinated/Non-Chlorinated

Hardness (CaCO

3

)

<350 (20 gpg)

Feed Water Pressure

1

242-690 kPa (35-100 psig)

Iron (Fe )

<0.1

Temperature

4°-38° C (40°-100° F)

Manganese (Mn)

<0.05

pH Range

3.0 - 11.0

Hydrogen Sulfide (H

2

S )

0.00

Maximum TDS Level

2000 mg/L

Residual Chlorine (Cl

2

) <2.0

Turbidity** <1.0

NTU

Maximum SDI***

<4.0

** Nephelometric Turbidity Unit

*** Silt Density Index: Value stated in SDI units.

NOTE: 1. PRESSURE REGULATOR IS RECOMMENDED FOR FEED WATER PRESSURES EXCEEDING 552 kPa (80 psig).

OPTIONS AND ACCESSORIES

PRODUCT WATER FAUCETS

BOOSTER PUMP

Faucets are available as Air Gap and Non-Air Gap in

Chrome-Plated Metal (EPA and California Proposition 65 Compliant)

or an Air Gap molded Polymer.

A booster pump may be used if system pressure is below 242 kPa (35 psi).

Pump should be placed near RO Module and installed in feed water line just

before it enters Module. Power supplies are available in a variety of voltages.

PUSH BUTTON SMARTAP

®

WATER QUALITY MONITOR

Indicator lights located on the module cover report system status.

Pressing a test button located on the manifold cover activates monitor.