Installation safety instructions – Burkert Type S030 User Manual

Page 6

20

7. inSTAllATion

Safety instructions

danger

risk of injury due to high pressure in the installation.

• Stop the circulation of fluid, cut-off the pressure

and drain the pipe before loosening the process

connections.

risk of injury due to high fluid temperatures.

• Use safety gloves to handle the fitting.

• Stop the circulation of fluid and drain the pipe before

loosening the process connections.

risk of injury due to the nature of the fluid.

• Respect the prevailing regulations on accident pre-

vention and safety relating to the use of hazardous

products.

English

21

Warning

risk of injury due to non-conforming installation.

• Fluidic installation can only be carried out by qualified

and authorised personnel with the appropriate tools.

• Observe the installation instructions for the measuring

device inserted into the fitting.

risk of injury due to an uncontrolled restart.

• Ensure that the restart of the installation is controlled

after any interventions on it.

Warning

risk of injury if the fluid pressure/ temperature

dependency is not respected.

• Take into account the fluid pressure/ temperature

dependency according to the materials from which the

fitting is made and to the measuring device used (see

the relevant user manual).

• Comply with the Pressure Directive 97/23/EC.

→

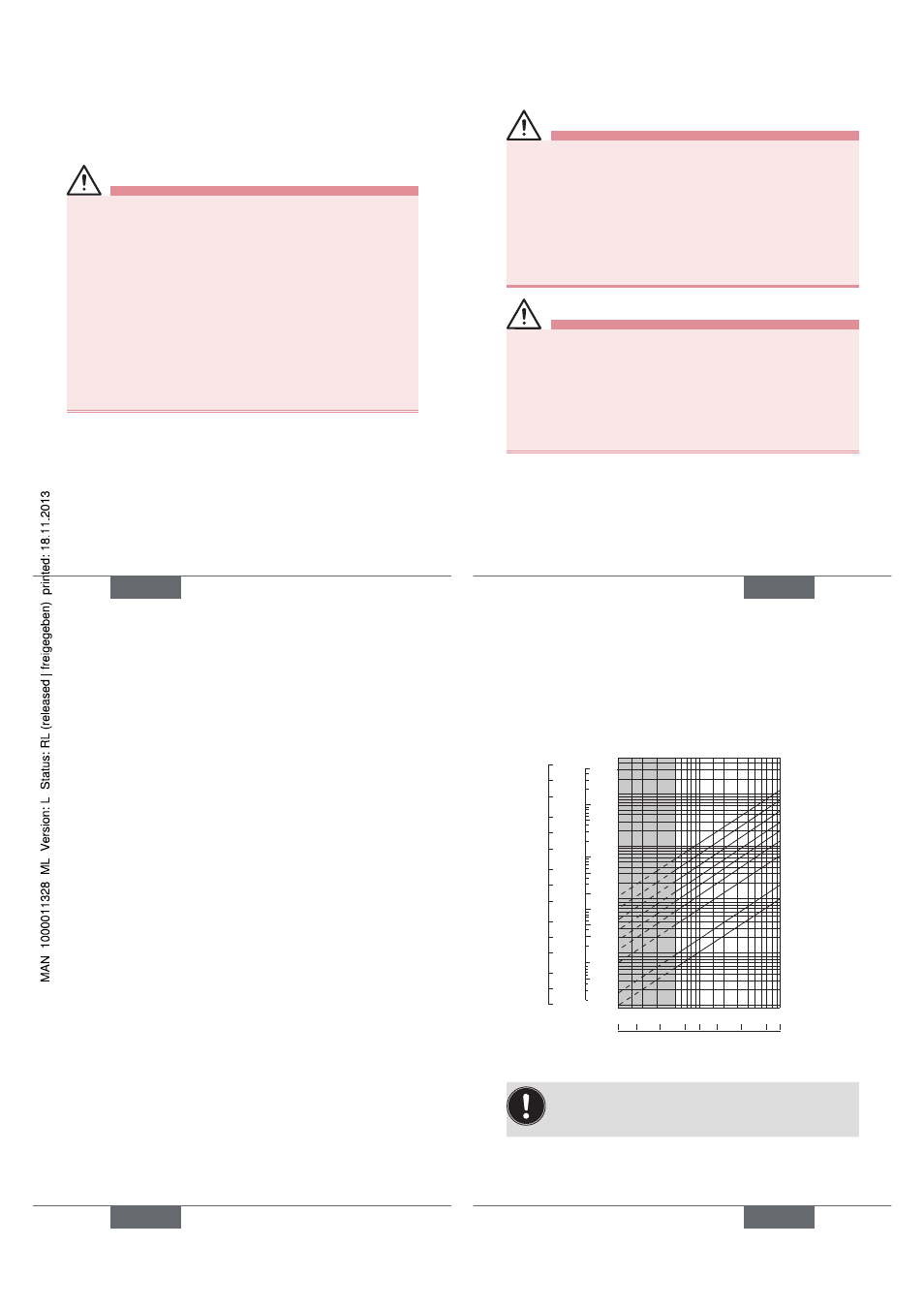

Select an appropriate fitting regarding to the flow

velocity and the flow rate of the fluid in the piping, see

the following charts:

English

21

22

The graph is used to determine the DN of the pipe and the

fitting appropriate to the application, according to the fluid

velocity and the flow rate.

Selection example:

• Specification: if the nominal flow is 10 m

3

/h, the dimen-

sioning of the optimal flow rate must be contained in 2

to 3 m/s

• Answer: on the chart, the intersection of flow rate and

flow velocity gives the appropriate diameter, DN40 or

DN50 for fittings with *.

* For fittings:

• with external threads according to SMS 1145,

• with weld ends according to SMS 3008, BS 4825 /

ASME BPE or DIN 11850 Rg2

• Clamp according to SMS 3017 / ISO 2852 or

BS 4825 / ASME BPE or DIN 32676

English

23

l/min

5000

1000

100

3

2

1

20

10

0.5

5

0.3

0.2

500

50

0.01

0.02

0.05

0.1

0.2

0.5

1

2

5

10

20

50

100

200

500

m3/h

m/s

fps

gpm

2000

1000

500

200

20

10

0.5

0.2

0.1

0.05

100

50

0.1 0.2

0.5 1

2 3 5

10

0.3 0.5 1

2 3 5

10 20 30

5

2

1

200

2000

DN65

DN50 (DN65)*

DN40 (DN50)*

DN32 (DN40)*

DN25 (DN32)*

DN20 (DN25)*

DN15 (DN15 or

DN20)*

DN08

DN06

flow rate

Fluid velocity

To reduce the water hammer effects, install a

special device such as an 80 bar calibrated

exhaust valve within the circuit.

→

Install the fitting on the pipe to comply with the

upstream and downstream distances defined by

standard EN ISO 5167-1 (see Fig. 2).

English

23