Assembly – Burkert Type 8644 User Manual

Page 9

9

Assembly

CAUTION!

Escape of medium and malfunction!

If the seals are not seated correctly, leaks and malfunctions may occur

due to pressure losses.

• Ensure that the seals are seated correctly in the area of the elec-

tronics and pneumatics.

Short-circuit, malfunction!

The electrical connection requires exact contacting.

• Do not bend contacts.

• If connections are damaged or bent, replace the affected

components.

• Do not switch on the system unless the components are in perfect

condition.

NOTE!

Operate the system with direct current only!

To prevent damage to the system, use only direct current for the

system power supply.

Prevent a pressure drop!

To prevent a pressure drop, design the system pressure supply with

the largest possible volume.

6.2. Assembly

DANGER!

Danger of explosion!

If systems in the explosion-protected area are installed in a control

cabinet, the following requirements must be met:

• The control cabinet must be authorized for use in the explosion-

protected area.

• The control cabinet must be large enough to allow the resulting lost

heat to be dissipated in a suitable manner to the outside.

• The internal temperature of the control cabinet must not exceed

the max. permitted ambient temperature for the device.

Risk of electric shock!

• Before reaching into the device or the equipment, switch off the

power supply and secure to prevent reactivation!

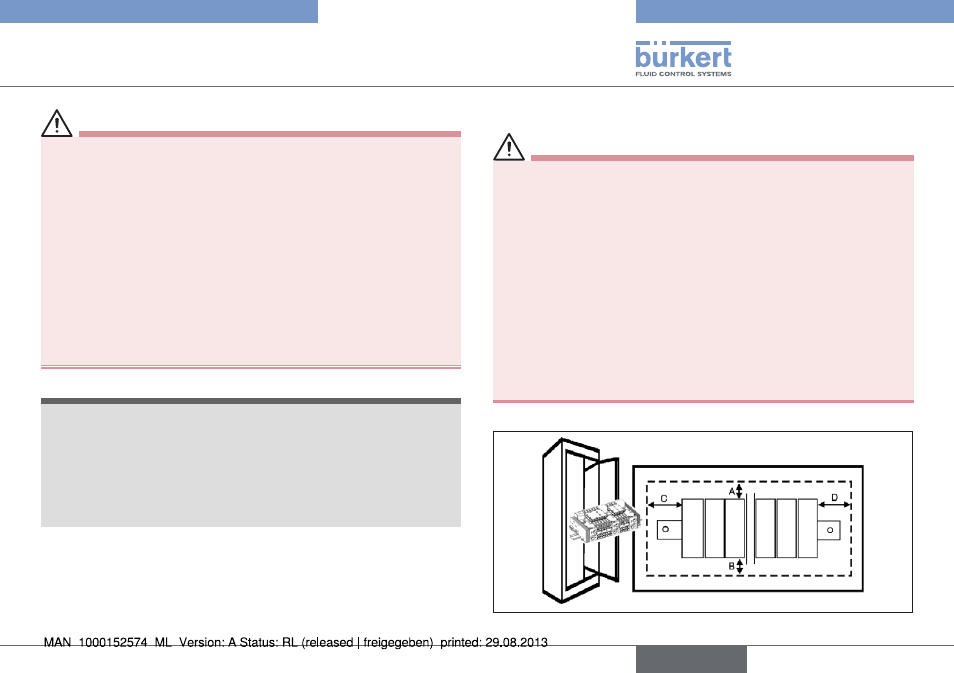

6.2.1. Installation on standard rail

Field

bus

Converter

Module

Module

Converter

Terminator

Fig. 4:

Installation of a valve block into a control cabinet

english

Type 8644