Installation, Fluid installation – Burkert Type 8644 User Manual

Page 13

13

Installation

There must be adequate space between valve block and pre-

decessor module > 6 mm.

→

Detach the modules/terminals from the standard rail according to

the manufacturer’s description.

NOTE!

The interface of the left connection module contains elements

which may break off if force is used.

• Never place the valve block on its side and observe the permitted

installation position.

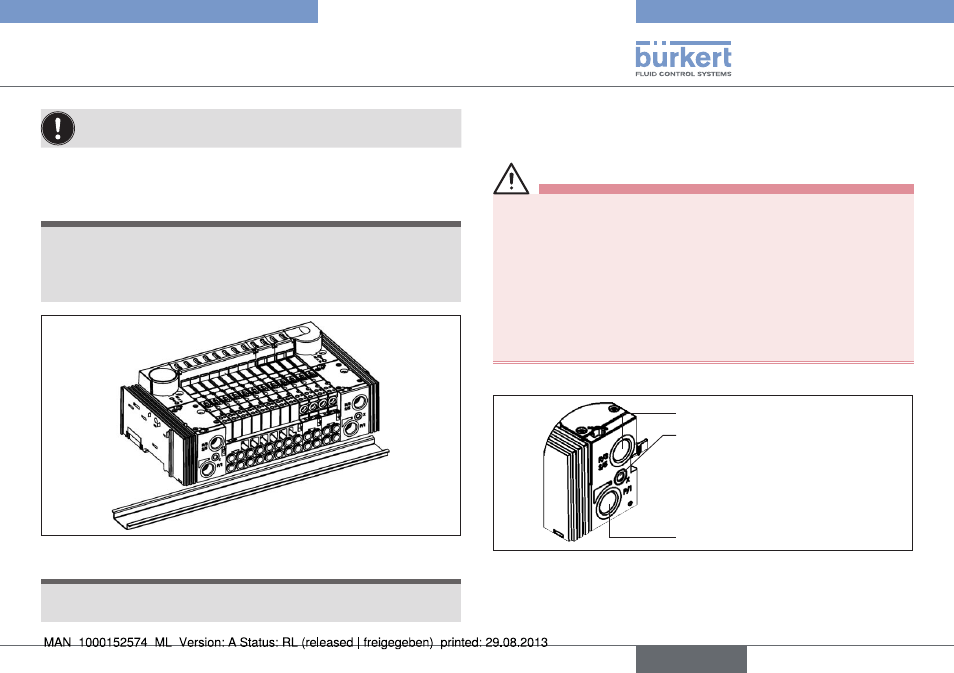

Fig. 9:

Detaching the modules/terminals from the standard rail

NOTE!

• When screwing the valve block back onto the standard rail,

observe a max. torque of 2 Nm!

7. INSTALLATION

7.1. Fluid Installation

DANGER!

Risk of injury from high pressure in the equipment!

• Before loosening lines or valves, turn off the pressure and vent

the lines.

• Design the connections with the largest possible volume.

• Close the open connections not required with lock screws.

• The connections for the pilot control exhaust air (x) must not be

sealed.

• Check correct assignment of the connections 1 and 3 or 5. They

may by no means be interchanged.

7.1.1. Pneumatic connections - feed

Exhaust air

Pressure supply connection

X channel:

Standard version:

Deaeration of the control valves

Control assist air version:

P connection for control valves

Fig. 10: Pneumatic Connections

Procedure:

→

Depending on the version, plug the connections in the corre-

sponding working connections or screw them in.

english

Type 8644