Burkert Type 5282 User Manual

Operating instructions type 5282

Operating Instructions

Type 5282

Design:

2-way solenoid valve, direct acting, normally closed (Circuit func-

tion A).

Seal Materials and Fluids handled:

See Table 1.

Fluid and Ambient Temperature:

For Hazardous Locations Div. 1 (T4 rated)

Max. Ambient Temperature

104 °F (40 °C)

Max. Fluid Temperature

194 °F (90 °C)

The UL-listed valve for Hazardous Locations is suitable for the

fluids air, inert gas, water and gasoline.

For Hazardous Locations Div. 1 (T6 rated)

Max. Ambient Temperature

104 °F (40 °C)

Max. Fluid Temperature

140 °F (60 °C)

For Intrinsically Safe Apparatus for use in Class I, II and III,

Division 1 Hazardous Locations (T6 rated)

Max. Ambient Temperature

140 °F (60 °C)

Max. Fluid Temperature

140 °F (60 °C)

For Hazardous Locations Div. 2 and Ordinary Locations:

See Table 1.

Pressure Range:

Maximum inlet pressure see label on valve.

Installation:

Before installing valve ensure that piping etc. is free of foreign

matter (metal shavings, pipe sealing materials, welding scale etc.).

Installation as required but preferable with coil uppermost. Instal-

lation in this position tends to prevent foreign matter remaining in

core tube (increased life). Do not put any loads on coil unit.

PTFE tape is recommended for sealing ports. The arrow on the

valvebody indicates the direction of flow.

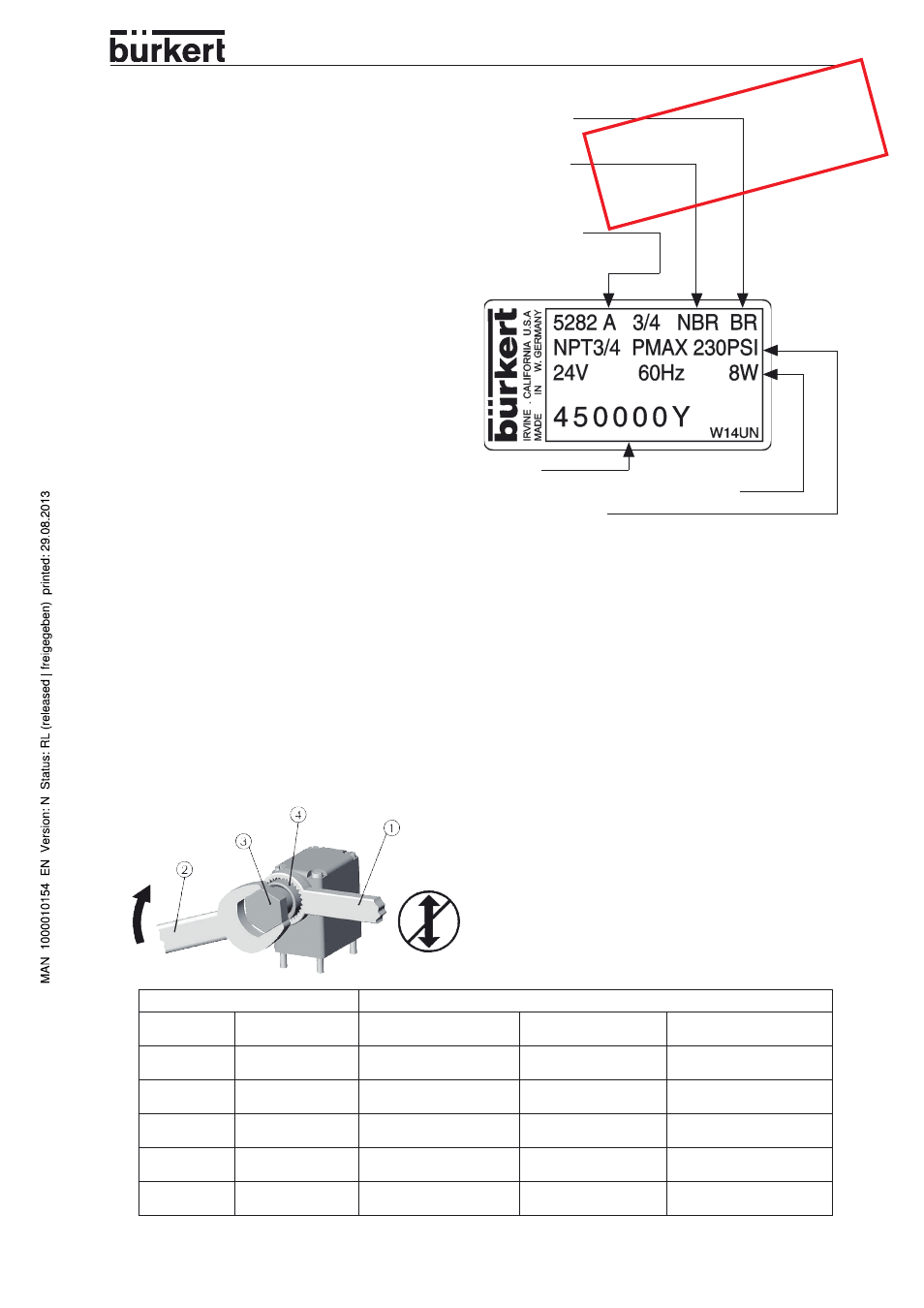

Assembly instructions:

The conduit connector on the coil (4) must be supported against

torque during the assembly using appropriate tools (1) (i.e. pliers,

gripper...) (for example a gripper).

While tightening for example a fitting (3) into the conduit connec-

tor attention must be paid to the fact that a max. torque of 20Nm

(177lbf in) is not exceeded.

Marking (example):

Body Material

BR =

Brass

SS =

Stainless Steel

Seal Material

EPDM

NBR

FKM

Circuit function

A =

Normally Closed

B =

Normally Open

Item No.

Voltage / Frequency / Power Consumption

Maximum Pressure

Approvals

The valve is either approved as

General Purpose valve for Hazardous Locations

Class I, Division 1, Group A, B, C, D

Class II, Division 1, Group E, F, G

Class III, Division 1 and 2

Operating Temperature T 4

or

General Purpose valve for Hazardous Locations

Class I, Division 1, Group A, B, C, D

Class II, Division 1, Group E, F, G

Class III, Division 1 and 2

Operating Temperature T 6

or

Intrinsically Safe Apparatus for Hazardous Locations

Class I, Division 1, Group A, B, C, D

Class II, Division 1, Group E, F, G

Class III, Division 1

Operating Temperature T 6

or

FM approved as

Nonincendive for Hazardous Locations

Class I, Division 2, Group A, B, C, D

Class II, Division 2, Group F, G

Class III, Division 1 and 2

Operating Temperature T 4

UL listed for General Purpose

CSA approved for General Purpose

See label on the valve.

Operating Instructions 1105/11_EN-EN_00801551

Seal materials

Fluid

Temperatures [°F]

NBR

EPDM

FKM

Air

Fluid

Ambient

+ 32 to + 176

+ 32 to + 131

- 22 to + 194

+ 14 to + 131

+ 32 to + 194

+ 32 to + 131

Water

Fluid

Ambient

+ 41 to + 176

+ 32 to + 131

+ 41 to + 194

+ 14 to + 131

+ 41 to + 194

+ 32 to + 131

Neutral gas

Fluid

Ambient

+ 32 to + 176

+ 32 to + 131

- 22 to + 194

+ 14 to + 131

+ 32 to + 194

+ 32 to + 131

Light oil

Fluid

Ambient

+ 32 to + 140

+ 32 to + 131

+ 32 to + 140

+ 32 to + 131

LP-gas

Fluid

Ambient

+ 32 to + 140

+ 32 to + 131

+ 32 to + 140

+ 32 to + 131

Voltage 12V or 24V

UL / UR valid with

class 2 power supply only