Burkert Type 0420 User Manual

Operating instructions type 0420

Operating Instructions

Type 0420

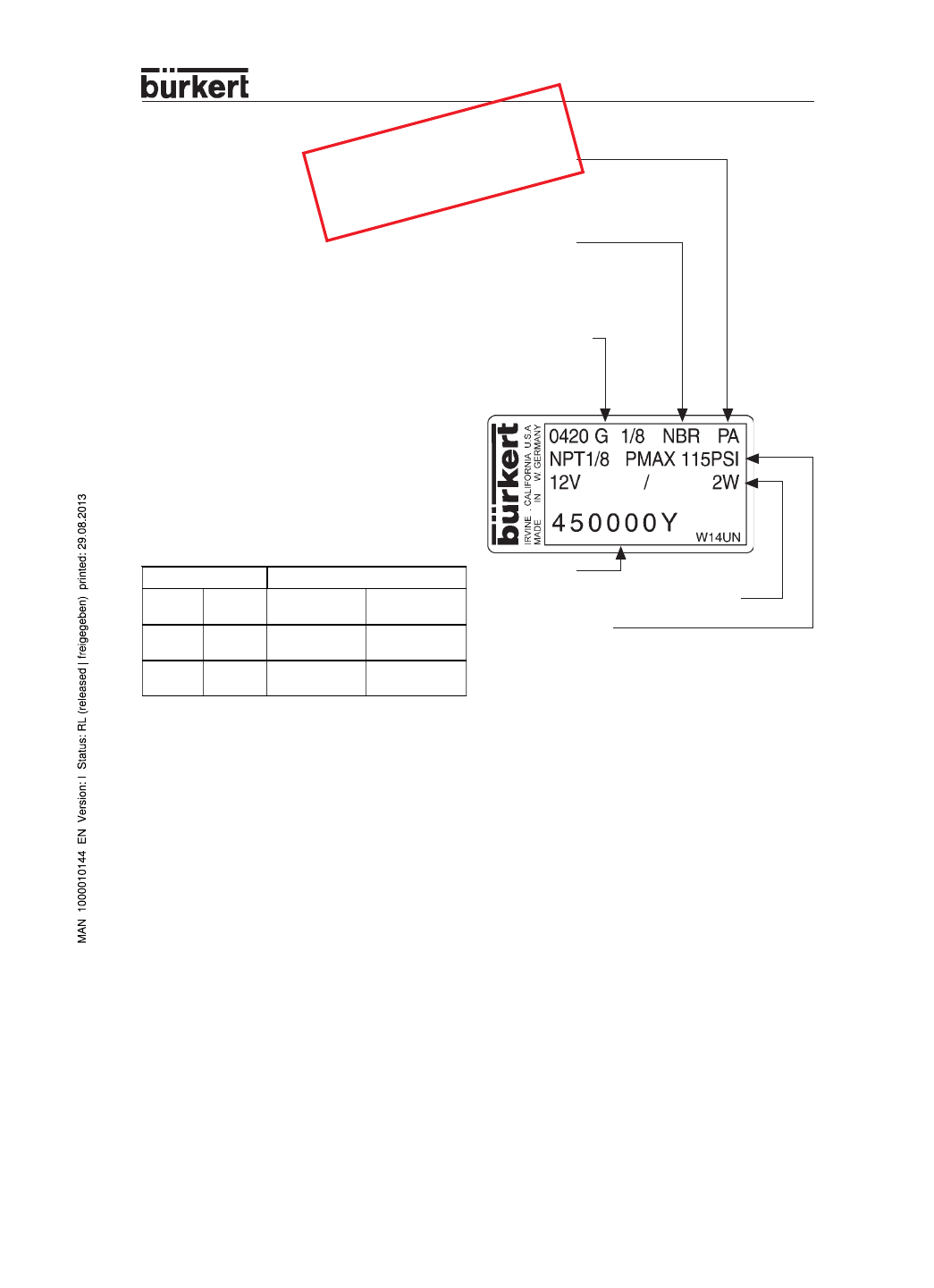

Marking (example):

Body Material

PL

=

Polyamide Plastic

Seal Material

NBR

=

NBR

FKM

=

FKM

Circuit Function

G =

4-way

Recorder No.

Voltage / Frequency / Power Consumption

Maximum Pressure

Approvals

The valve is either approved as

General Purpose valve for Hazardous Locations

Class I, Division 1, Group A, B, C, D

Class II, Division 1, Group E, F, G

Class III, Division 1 and 2

Operating Temperature T 4

or

General Purpose valve for Hazardous Locations

Class I, Division 1, Group A, B, C, D

Class II, Division 1, Group E, F, G

Class III, Division 1 and 2

Operating Temperature T 6

or

FM approved as

Nonincendive for Hazardous Locations

Class I, Division 2, Group A, B, C, D

Class II, Division 2, Group F, G

Class III, Division 1 and 2

Operating Temperature T 4A

UL listed for Ordinary locations

CSA approved for Ordinary locations

See label on the valve.

Operating Instructions 0605/08_EU-EN_00893139

Table 1

Seal materials

Fluid

Tempera-

tures [°F]

Buna "N" (B)

FKM (F)

Air

Fluid T.

Ambient

+ 14 to + 122

+ 14 to + 122

+ 14 to + 122

+ 14 to + 122

Neutral

gas

Fluid T.

Ambient

+ 14 to + 122

+ 14 to + 122

+ 14 to + 122

+ 14 to + 122

Design:

4-way solenoid valve, internally piloted, in the de-energized

condition port P connected to port B and port R connected to

port A. With manual override and flow restrictors.

Seal Materials and Fluids handled:

See Table1.

Fluid and Ambient Temperature:

For Hazardous Locations Div. 1 (T6 rated)

Max. Ambient Temperature

104 °F (40 °C)

Max. Fluid Temperature

140 °F (60 °C)

For Hazardous Locations Div. 2 and Ordinary Locations:

See Table1.

Pressure Range:

Minimum pressure differential between inlet and outlet port is

35 PSI.

Maximum inlet pressure see label on valve.

Installation:

Installation position as required. Ensure exhaust outlets for

pilot valve and main valve remain unrestricted but protect

against entry of dust, water and foreign matter. Pipework

should be clean. Do not put any loads on coil unit. Pipework

should be supported and installed to prevent strain on valve

body. Fittings should be sealed with PTFE tape, max. torque

80 in-lbs. Mounting is accomplished by means of two M4 self-

locking threaded brass inserts located on the valve

underside. Maximum thread depth is 6 mm.

Voltage 12V or 24V

UL / UR valid with

class 2 power supply only