Hall effect sensor (pulser) – Fill-Rite TM Series Precision Meter User Manual

Page 8

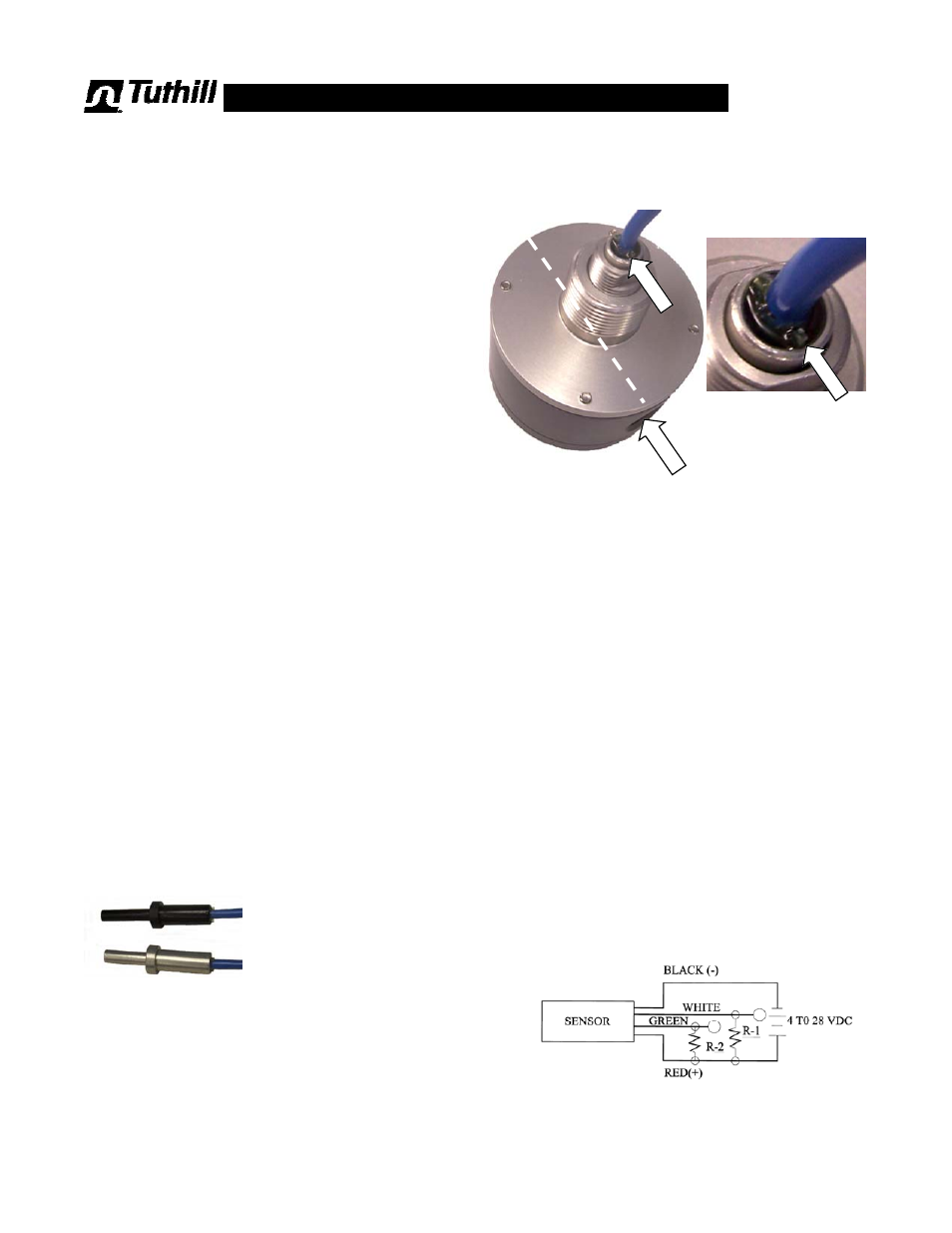

To install a new sensor, look at the top of the replacement

sensor. An internal PC board is visible through the epoxy

(usually protrudes slightly from the epoxy). This PC board

must be aligned parallel with a line drawn between flow

meter inlet and outlet.

Close-Up

Trouble Shooting the Sensor

There are three components to be examined to determine

why there is no pulse count coming from the flow meter:

1. Flow meter with magnets in the oval gears.

Verify that liquid is flowing.

Verify that sensor (pulser) cable is intact.

2. The sensor (pulser)

Remove the sensor from the flow meter. Expose

the black & white leads (in dual signal sensors, also

the green lead). This can be done at a convenient

junction, or at the register.

Use an volt meter to measure the voltage between

the white & black leads. It should be nearly equal to

the power supply voltage provided on the red lead.

Pass a magnet across the tip of the sensor. The

voltage must switch to nearly zero (less than 0.2 V).

If the magnet does not actuate the sensor, the sen-

sor has failed.

For two channel sensors, repeat this test across

black & green leads.

3. The counter (or receiving instrument)

If liquid is flowing, and the sensor reacts to a mag-

net, the problem is in the counter/receiving instru-

ment (or possibly in a signal conditioner installed

between the sensor & counter/receiving instrument.

Please refer to the manual for the this device.

See Control Drawing on page 1.10

Intrinsically Safe rated sensors for

Cl. 1, Div. 1, Grp. D and Zone 0 applications

CD1002, UL 9HA6, DEMKO 04 ATEX0334817 EEx ia IIA T4

The standard sensor (pulser) is a Hall Effect device, which

may have one or two output signals. To retain above ratings,

it must be powered from a secure circuit through an approved

barrier. A PIA-300 signal conditioner may be required, when

connected to non-FPP electronics

Specifications:

Operating speed : 0-100 kHz.

Operating temperature : -40ºF/+300ºF (-40ºC to +150ºC)

Supply voltage : 4-28 VDC

Supply current : 13.5 mA max.

Output

type : SINK

(add PIA-300 for source)

Output voltage @ 20 mA: 0.40 V max

Output sink current : 20 mA max

Leakage current : 10

μ

A max

Magnetics type : Bipolar, operated with alternat

ing

north

&

south

magnetic

poles.

Internal pull-up resistor : 10KΏ

Transmission distance : Max. 100’ (30 m)

without PIA-300

Pull-up Resistor (R1 & R2)

The sensor has one internal 10KΏ pull-up resistor for each

output signal. If used directly with non-FPP electronics, verify

whether this is adequate for solid communications.

Cable

24 AWG, foil shield & drain wire, blue PVC jacket, RoHS.

75VDC. Capacitance: 185 nF/km. Inductance: 0.65 mH/km.

Standard with 18” (45 cm) leads. 120” (305 cm) or

480” (1220 cm) leads optional.

Color

Code:

Red

Positive,

4-28VDC

Black Negative (signal common)

White Signal output A

Green Signal output B (optional)

3 conductor: Standard Hall Effect sensor

4 conductor: Dual signal Hall Effect sensor (Quadrature)

2 conductor: Optional Reed Switch sensor (see page 1.9).

A PIA-300 amplifier is required for cable lengths exceeding

100’ (30 m).

Easy Identification of replacement sensors

Black anodized housing is for

TM04 & TM06 models.

Metallic finish is for use in

TM02 & TM03 models

Installation

Do NOT remove the sensor (pulser) from the flow meter

,

unless

trouble shooting has indicated a problem in the sen-

sor. To remove the sensor, loosen the lock nut on the sen-

sor retainer (sensor well in model TM06). The sensor can

now be pulled out.

CAUTION

If the sensor is

connected incorrectly,

it will be damaged

beyond repair.

PC

b

oa

rd

PC

b

oa

rd

I N

L

E

T

1 . 8

Hall Effect Sensor (Pulser)