Fill-Rite TM Series Precision Meter User Manual

Page 23

P hn: 2 6 0- 7 4 7 - 9 0 6 0

US: 8 8 8- 5 7 8 - 3 2 5 8

F a x: 8 0 0- 8 6 6 - 4 8 6 1

www.t ut hill.c o m

F P P We bInquirie s @ t ut hill.c o m

N a me

P ho ne

D a t e

C o mpany

E -mail

To ensure correct selection of flow meter and possible accessories, please provide the following details:

Liquid(s) to be metered:

FLOW RATE:

NORMAL

MIN:

MAX:

G P M G P H LP M LP H M

3

/ H

TEMPERATURE:

MIN:

MAX:

°F °C

PRESSURE:

NORMAL

MIN:

MAX:

P SI B A R k g

2

/ c m k P a P a M pa

VISCOSITY:

@ NORM Temp:

@ MIN Tem p:

SS U c St mm

2

/ s c P mP a ●S

TYPE of PUMP:

Type of operation:

Custody Transfer service

Non-custody transfer,

specify accuracy required

: +/- %

Area classification:

Non-Hazardous

Hazardous. Distance to nearest non-hazardous location: __________

Accessories:

Registration, Functions & Communications:

Strainer

Register

Local

Remote

Local & Remote

Strainer/Air Eliminator

Preset/Batching

with pump control

High Capacity Strainer/Air Eliminator

Printer

Local

Remote

Local & Remote

Backpressure Valve

Rate of Flow display per MIN HOUR DAY

Air Check Valve

Temperature/Volume comp.

Preset Valve, mechanical

Currency function

2-stage electronic preset valve

Remote operation

1-stage system security valve

Pulse signal

Resolution/unit:

Distance:

Analog signal

4-20 mA

0-20 mA

other:

Flanges:

Transaction data to PC

Serial Port

Wireless

Threaded companion flanges

Welding companion flanges

without register, specify:

Model:

150# RF ANSI flange adaptors

Voltage:

Circle units used

etc.

a7 :

b7 :

a8 :

b8 :

b3 :

b4 :

b5 :

b6 :

c7 :

c8 :

c5 :

c6 :

c3 :

a3 :

a4 :

a5 :

a6 :

b1 :

D

a1 :

a2 :

D :

b2 :

c1 :

c2 :

c4 :

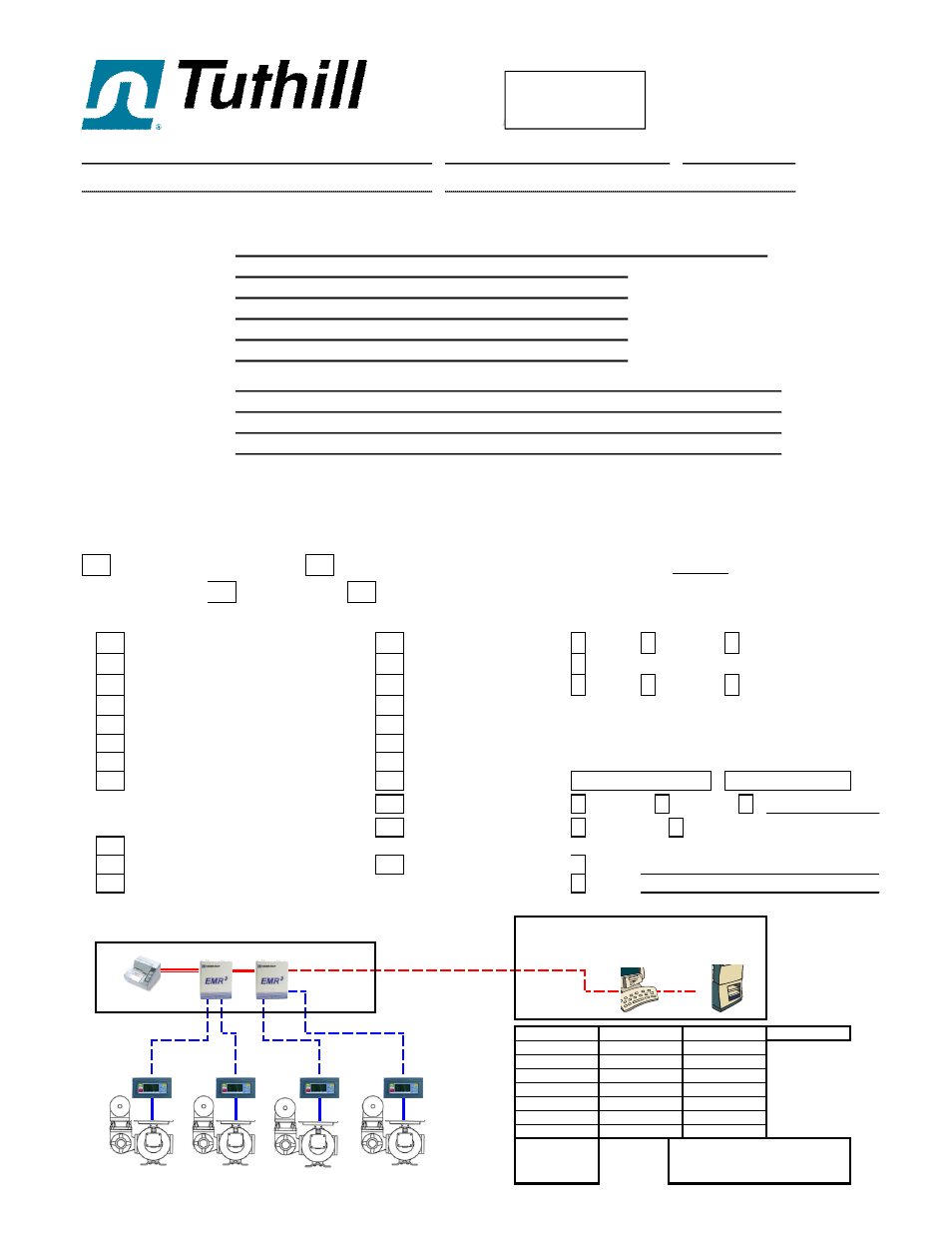

Office/Company computer & printer

= 0 if register

is installed o n

flo w meter

When BOTH lo cal & remo te register,

C = the distance fro m interco nnect

bo x to remo te register

b1

b2

b3

b4

Non-Hazardous & Indoor location

a1

a2

a3

I

II

III

IV

Please describe the

system (such as: Retail

tank truck, rail road

fueling in depot, etc.)

When making a choice betw een mechanical & electronic register, consider that the electronic system has low er maintenance requirements,

and it is alw ays more accurate than the equivalent mechanical system due to less drag on the flow meter.

For a single flow meter, the mechanical register is usually the low er initial cost. For 2-3 flow meters in one system/installation, the cost is

usually comparable (w ithin 5-10%). For 4 or more flow meters in one system, the electronic solution is usually the low er initial cost.

Printer

In multi-meter systems with EMR

3

register, specify distances:

a4