Fill-Rite FR4410DBFQ User Manual

A trusted name . . . quality you deserve, Danger filter replacement, Filter installation

FR4210DBFQ and FR4410DBFQ

4200G9450rev 1

Tel 260 747-7524 Fax 260 747-3159

Fort Wayne, Indiana USA 46809

8825 Aviation Drive

www.tuthill.com

A Trusted Name . . . Quality you Deserve!

1. 800F4400

1" Street Elbow

2. 400F3651

1" X 7 1/4" Nipple

3. 304F7885

1" X 90º Elbow

4. 316F8417

1" X 3" Nipple

5. 300ACCG9333 Filter Head

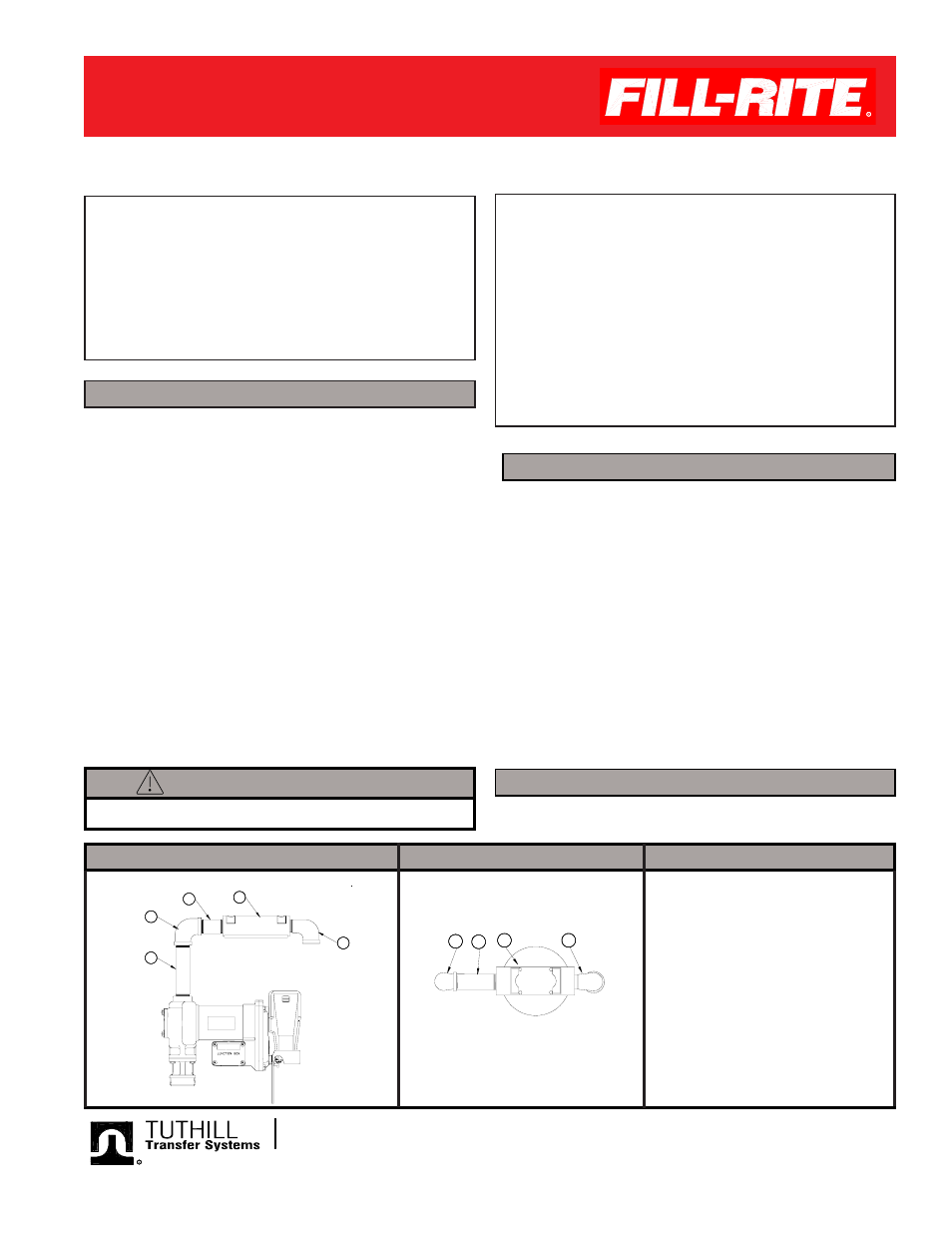

Parts

Top View (less pump)

Front View

1

2

3

4

5

3

4

5

1

IN

FR4210DBFQ

•Pumps gasoline, diesel fuel, and kerosene

•Heavy duty cast iron construction

•Thermally protected motor

•Automatic nozzle with hang-up hook

•Delivers up to 100 Gallons (376 Liters) in less than 6 minutes with

automatic nozzle 300F7801. Slightly higher flow rate can be

achieved with 1" manual nozzle. Expect a loss of flow rate (GPM)

whenever the nozzle outlet is higher than the pump outlet.

Box Contents:

Series 4200 High-Flow DC pump

*H100G9207

20 Ft. x 1" Fueling Hose

*4200G9349

25 Ft. 10 Ga. 3-wire Power Cable with Heavy Duty

Industrial Battery Clamps

*F4030PM0

High-Flow 30-Micron Particulate Filter

*300F7801

Automatic Nozzle

4200F9111

Nozzle Hook

*1200KTG9099

1" Steel Telescoping Suction Pipe

Pipe Fittings

Teflon® Tape

Owner's Manual

* Order above part numbers instead of part numbers shown in enclosed

owner's manual when ordering replacement hose, nozzle, power

cable and filter for the Fill-Quik pump.

Pump and filters not for use with aviation fuels.

DANGER

FILTER REPLACEMENT

Read and follow all safety information. Filter must be installed using rigid

metal piping.

1.

Remove power to pumping unit.

2.

Follow OSHA Lockout/Tagout procedures.

3.

Clear area of pedestrians and vehicles.

4.

Turn off fuel to pump. Operate nozzle until no flow occurs. Pump

should not be running at this point.

5.

Connect all pipe fittings and filter head as shown in diagram. Position

filter head so that filter mounts vertically (text should read left to

right). Use gasoline and oil resistant pipe compound on all pipe joints.

6.

Apply thin film of lubricating oil to gasket of new filter. Do not use

fuel oil.

7.

Screw filter onto flow adapter until gasket makes contact.

8.

Tighten filter by hand.

9.

Turn on fuel supply.

10. Apply power to pump.

11. Pressurize system and check for leaks.

FILTER INSTALLATION

Replace filter on a semiannual basis or when flow rate has dropped. Follow

installation instructions, omitting step 5 above.

To ensure safe and efficient operation, it is essential to read and

follow each of these warnings and precautions.

1.

Improper use or installation of this product can cause

serious bodily injury or death.

2.

Maximum pressure: 50 PSI/3.45 BARS. Filters should not be used

on systems with more than 40 PSI/2.76 BARS without pressure

differential gauges.

3.

Do NOT smoke or use power tools near filter, or use filter near

an open flame when filtering flammable fluids. Fire could result.

4.

All spilled fuel must be collected. Use and disposal of these

products is controlled by federal, state or local laws and

procedures.

5.

A surge dampening device must be installed with filter if system

contains additional check valves, long hoses or excessive piping

to prevent filter leakage or rupture.

6.

Wear goggles when installing filters to avoid eye injury.

7.

Wear a static control wrist strap when installing filter to prevent

fire or explosion.

8.

Do NOT use a foot valve in conjunction with fuel filter. Explosion

could result.

9.

Refer to Owner's Manual prior to installation.

SAFETY INSTRUCTIONS