Tm series, specifications & capacity, Materials, Pressure rating – Fill-Rite TM Series Precision Meter User Manual

Page 4: Temperature rating, Flow meter nominal capacity, Ae & k, Rotor code, Flow meter coefficient

Materials

:

TM

●●

A

Case & cover : Anodized aluminum

Posts

(shafts) : 316SS

Seal : Viton™ std., Teflon™ optional

TM

●●

C

Case & cover* : 303SS

Posts

(shafts) : 316SS

Seal

: Teflon™

standard

TM

●●

D

Case & cover* : 316SS

Posts

(shafts) : 316SS

Seal

: Teflon™

standard

Rotors (oval gears) : TM02 SS/Teflon

bearings

TM03 PPS

standard,

SS/Teflon bearings opt.

TM04 PPS

standard

TM06 PPS

standard

*

Pulser retainer (exterior non-wetted fitting) is anodized aluminum.

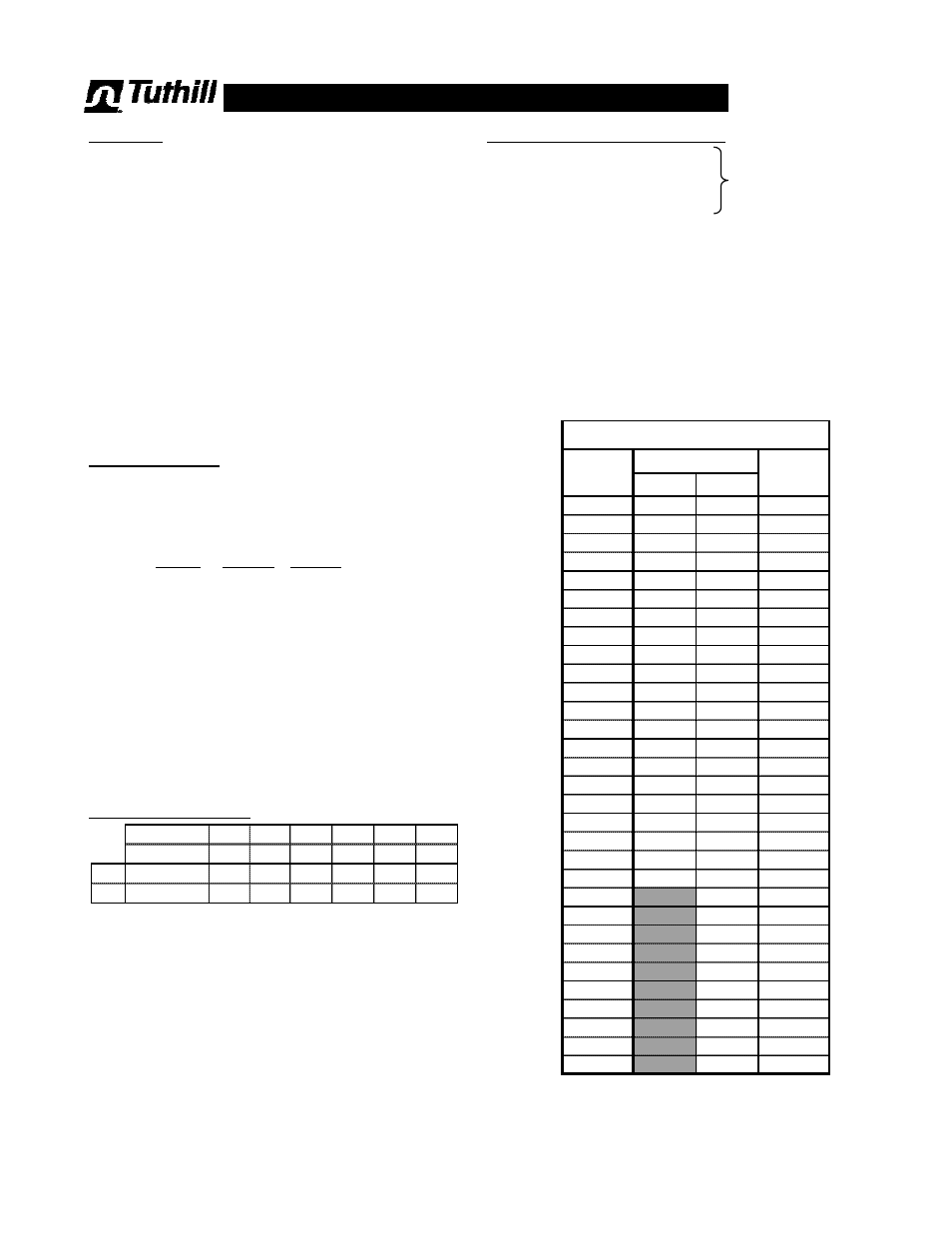

Pressure Rating:

TM Series meters are manufactured with 2 different pres-

sure ratings (though not in all sizes/materials). Pressure

rating is identified in position 11 in the Part Number:

Pos.

11

in P/No.

K L

F

obsolete 2009

1500

PSI 2500

PSI

400 PSI

MODEL

103

BAR 173

BAR

28 BAR

TM02D

TM03A

TM03D

TM04A

TM04C

TM04D

TM06A

TM06C

TM06D

Pressure rating applies to -40ºF/+100ºF (-40ºC/+38ºC) tem-

perature range. At higher operating temperatures the pres-

sure rating is reduced by factors shown below

:

Temperature Rating:

TM Series meters are rated for use on liquids with tempera-

ture in -40ºF/+300ºF (-40ºC/+150ºC) range. This tempera-

ture rating applies to the flow meter only.

Electronic signal conditioner, totalizer or register attached to

the flow meter will have a different rating, which may differ at

both the low and high end of the range (refer to manual for

electronic components). When that is the case, the elec-

tronic component must be installed remote from the flow

meter.

Flow Meter Nominal Capacity:

TM02D 0.3

GPM

1.1

lpm

TM03 3.0

GPM

11

lpm

TM04 10

GPM

38

lpm

TM06 20

GPM

76

lpm

Actual capacity depends upon liquid lubricity, viscosity and

operating temperature. Normal turn-down is 10:1 from nom-

inal (maximum) value shown. Optimum performance is be-

tween 50% and 85% of nominal capacity.

When the viscosity exceeds 200 cSt, maximum flow rate is

restricted, but the flow meter will have satisfactory linearity

(accuracy) down to 2-3% of nominal capacity.

To determine model maximum capacity on higher viscosity

liquids, find the flow meter coefficient for maximum liquid

viscosity in table below, and multiply nominal capacity with

this factor.

1 . 4

-40°F/+100°F 150°F 200°F 225°F 250°F 275°F 300°F

-40°C/+100°C 66°C 93°C 107°C 121°C 135°C 150°C

A.A.

1.00

0.89

0.79

0.75

0.72

0.62

0.43

S.S.

1.00

0.91

0.83

0.79

0.74

0.70

0.67

On liquids with

1 cSt viscosity.

A

E & K

1

cSt

1.000

1.000

32

SSU

10

1.000

1.000

60

50

1.000

1.000

240

100

1.000

1.000

475

200

1.000

1.000

925

300

0.855

0.855

1,425

400

0.770

0.770

1,875

500

0.710

0.710

2,350

600

0.660

0.660

2,825

700

0.625

0.625

3,300

800

0.595

0.595

3,775

900

0.560

0.560

4,250

1,000

0.540

0.540

4,725

2,000

0.350

0.350

9,450

3,000

0.275

0.275

4,000

0.240

0.240

5,000

0.190

0.190

6,000

0.160

0.160

7,000

0.135

0.135

8,000

0.115

0.115

9,000

0.100

0.100

0.085

0.072

0.061

0.052

0.044

0.037

0.031

0.026

0.022

0.019

Rotor Code

60,000

70,000

80,000

Liquid

Viscosity

141,600

188,800

236,000

283,200

330,400

377,600

424,800

90,000

472,000

Liquid

Viscosity

Flow Meter Coefficient

100,000

10,000

20,000

30,000

40,000

50,000

14,150

18,875

23,600

28,325

94,400

33,050

37,750

42,475

47,200

TM Series, Specifications & Capacity