Datamax-O'Neil I-Class Linear Scanner User Guide User Manual

Page 8

6

Alignment

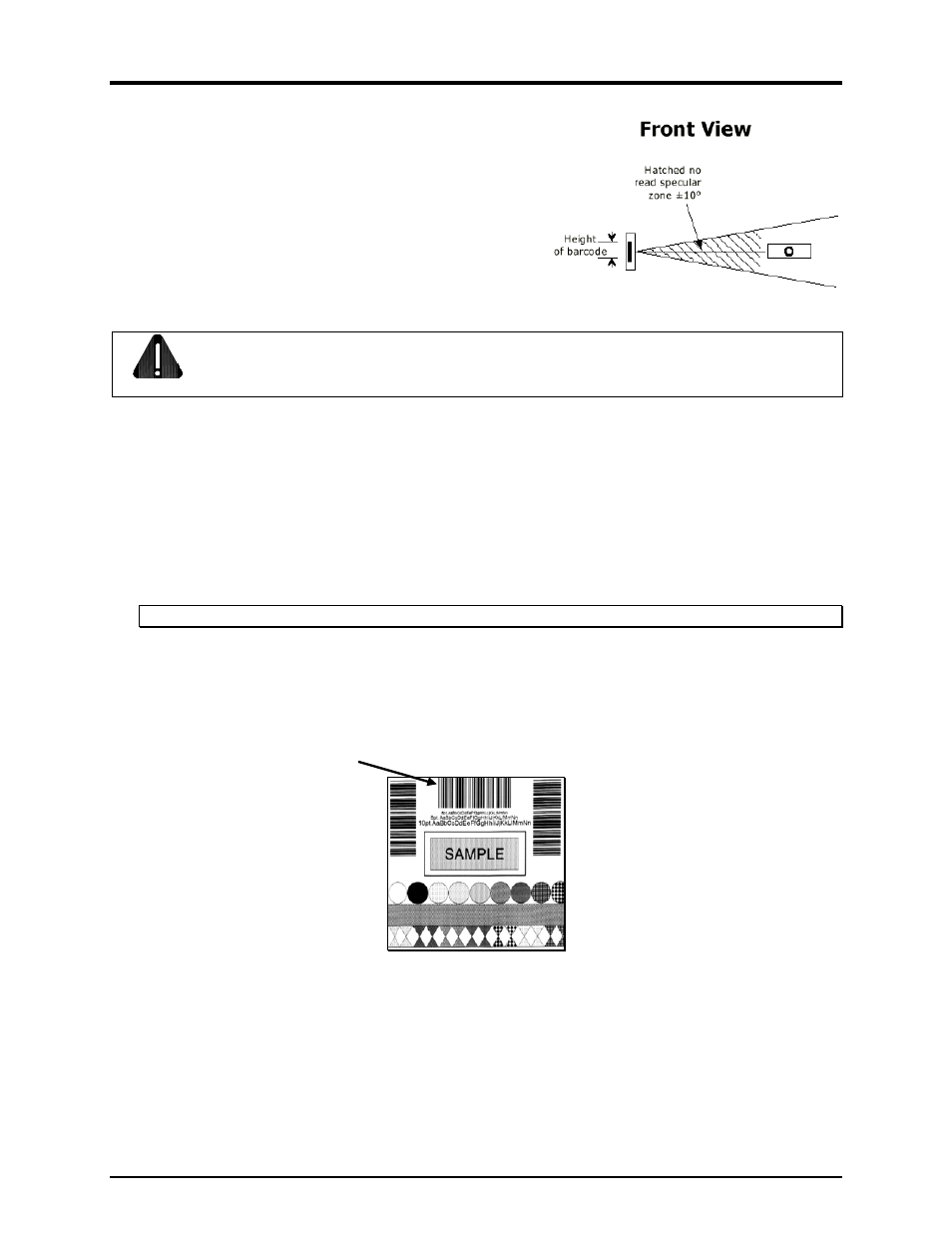

Avoiding Specular Reflection

The Scanner is factory-adjusted for optimum performance.

If, however, the label exit angle changes (due to, for

example, the addition of a peel mechanism or an external

rewinder), normally good bar codes may fail because of

excessive specular reflection. A high level of reflection can

“blind” the internal optics. The diagram (right) illustrates

the no read specular zone, between 0 to 10 degrees off

perpendicular.

CAUTION

The use of controls, adjustments, or the

performance of procedures other than those

specified herein may result in hazardous LED light exposure. Class 1 LED power up to 15

mW in a 0.1 ms pulse at 635-670 nm could be accessible in the interior.

To reduce specular reflection, follow the steps listed below:

1)

Ensure that the Tear Bar, Peel Mechanism, or Rewind Plate has been mounted to the printer (if using

an external rewinder, attach the labels to the rewinder). See the I-Class Operator’s Manual for

mounting details.

Note:

The cutter option cannot be used when the Scanner is installed.

2)

With four-inch wide label stock installed, use the printer’s front panel and enter ‘QUICK TEST

MODE.’ Print a Print Quality Label, as shown below (see the I-Class Operator’s Manual for details).

3)

Unlock the Printhead Latch and raise the printhead assembly. Carefully position the Print Quality

Label so that it comes straight out of the printer, and so that only the bottom ¼ inch of the Picket

Fence Bar Code is showing from the Ribbon Shield (see drawing below). Lower the printhead

assembly and lock the Printhead Latch.

Picket Fence Bar Code