CEMB USA N300 User Manual

Page 82

CONDITIONS OF VALIDITY OF THE BALANCING TOLERANCE GRAPH

1. The balancing values refer to the entire rotor; if there are two

planes of correction and if the rotor is approximately symmetrical,

each correction plane should be allotted a tolerance value equal

to half the value found, as long as the correction planes are

symmetrical with respect to the barycentre and the pedestals;

in

the case of marked asymmetry in the rotor or in the position of the

correction planes, the residual unbalance must be divided

accordingly between the two planes of correction.

2. The tolerance values arc valid both for static and for couple

unbalance.

3. A rotor should be considered to be rigid over its complete range of

service speeds and in the actual working conditions of the machine

itself (bearings, pedestals, bedplates, foundations, couplings with

other rotors, drive elements, etc.).

NOTE 1 - Balancing grades 0,4 and 1

For class 0,4 and 1 rotors, balancing tolerance must normally be

checked with the direct experimental method.

The influence of the means of rotor drive and of the bearings may be

significant.

NOTE 2 – Use of auxiliary equipment

For rotors that must be mounted on auxiliary shafts or flanges for

balancing,

the tolerances shown are only meaningful if, as well as the

unbalance of the auxiliary shaft or flange, the play of the mounting and

the working tolerance of the piece are checked for their concentricity

with the rotational axis, both for the residual unbalances and of the

ultimate shaft. The sum of the residual unbalances and of the plays,

converted into eccentricity values, must, of course, be lower than the

balancing tolerance, as the balancing accuracy obtained would otherwise

be purely illusory.

NOTE 3 - Assembled rotors

For assembled rotors the unbalance of the component parts must be

summed together vectorially, also bearing in mind the unbalance that

derives from the mounting (machining tolerances, clearances, keys,

set screws, etc.).

The unbalance resulting after the assembling should be lower than that

indicated by the graphs for the complete rotor; if it is not, the rotor

should be balanced after assembly, selecting two suitable planes of

correction.

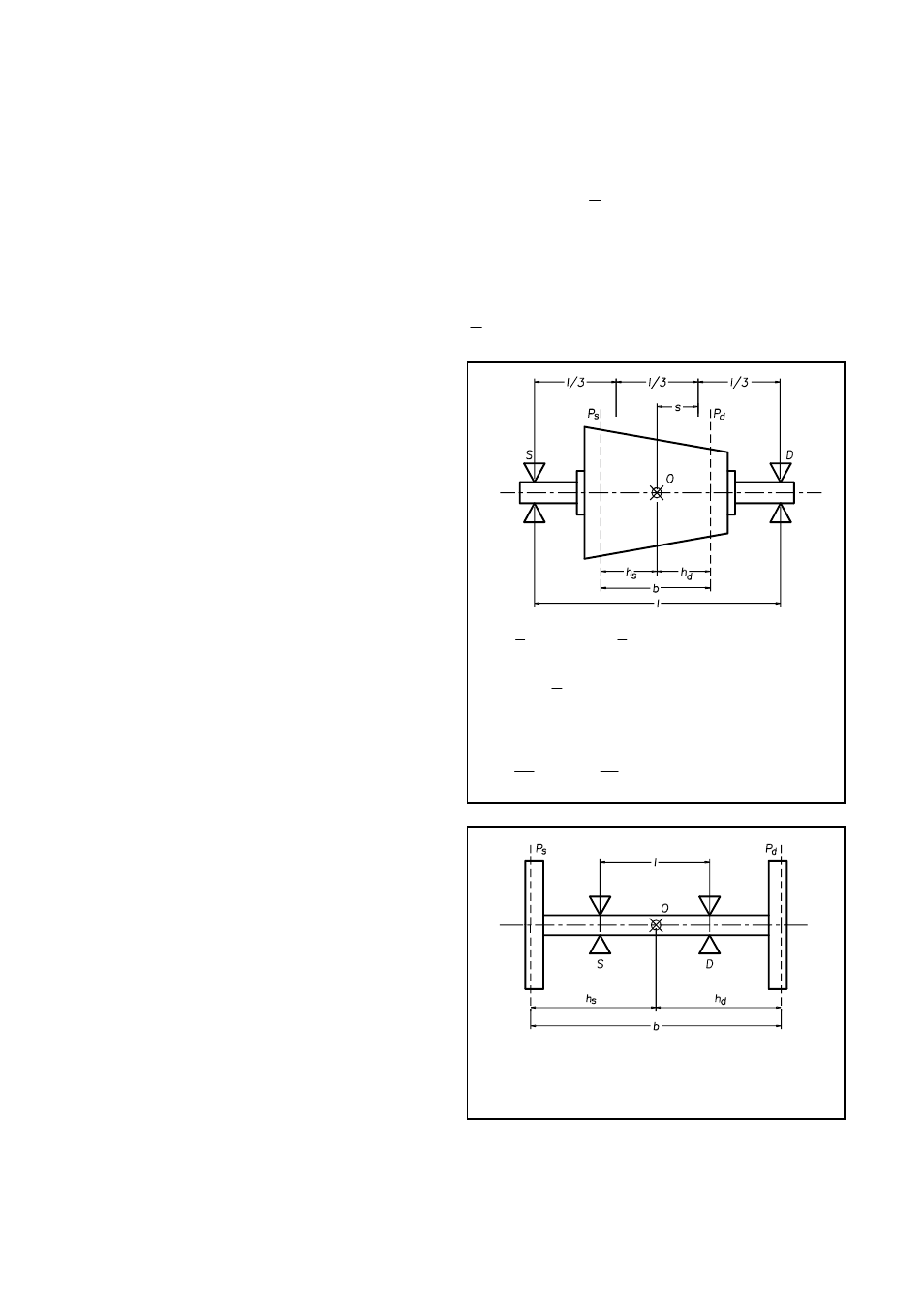

DIVIDING THE PERMISSIBILE RESIDUAL

UNBALANCE BETWEEN TWO CORRECTION

PLANES

In most rotors, a reasonable division of the total permissible

residual unbalance

U

of the rotor is possible between the two

correction planes using one of the following methods; choose

the method according to the conditions specified.

Us

and Ud are used to indicate the respective permissible

residual unbalances for the left and right correction planes (see

figures).

O

indicates the rotor’s barycentre.

1) If

l

b

l

<

<

3

;

3

l

s

<

with

d

s

h

h

≅

we can consider

U

U

U

d

s

2

1

=

=

With

d

s

h

h

≠

but

b

h

b

s

7

,

0

3

,

0

<

<

we can consider

U

b

h

U

d

s

=

;

U

b

h

U

s

d

=

2) If

l

b

>

it is advisable to consider a greater value of

overall unbalance

to be divided as above

DIRECT EXPERIMENTAL METHOD

The most accurate and safest value of the maximum permissible

residual unbalance can only be obtained with direct experiments.

To do this, balance the rotor on a balancing machine as accurately

as possible, then fit it on its ultimate machine in service

conditions. In successive tests, add increasing unbalances, until

the vibrations of the pedestals or of the machine become

significant. Now establish the maximum permissible unbalance

in relation to the value found, e/g. one third.

This testing must be systematic, so as to take all possible cases

of vibration and all possible conditions of the rotor and of the

position of the added unbalances into consideration.