Air feed features – PA Industries Precision AirFeed User Manual

Page 4

2

AIR FEED FEATURES

FASTER SPEEDS

Our patented system sequences

high speed models up to 400 cycles

per minute at full two inch pitch.

VERSATILE

Coil stock can be fed in any direction

or angle at any time during the

machine cycle. A single feed can

push or pull through long or short

progressions. A variety of stock

widths and thicknesses can be fed at

different speeds and feed lengths.

Two or more strips can be

simultaneously fed by the same feed.

INEXPENSIVE

The cost of P/A feeds are 65% to 90%

less than conventional roll or slide

feeds. With savings like that you

should consider leaving the feed

permanently mounted on the tool

to decrease set up time and increase

productivity.

Surveys show that Contract Job

Shop Stampers prefer P/A air feeds

because they are the easiest and most

economical way to change from one

job to another.

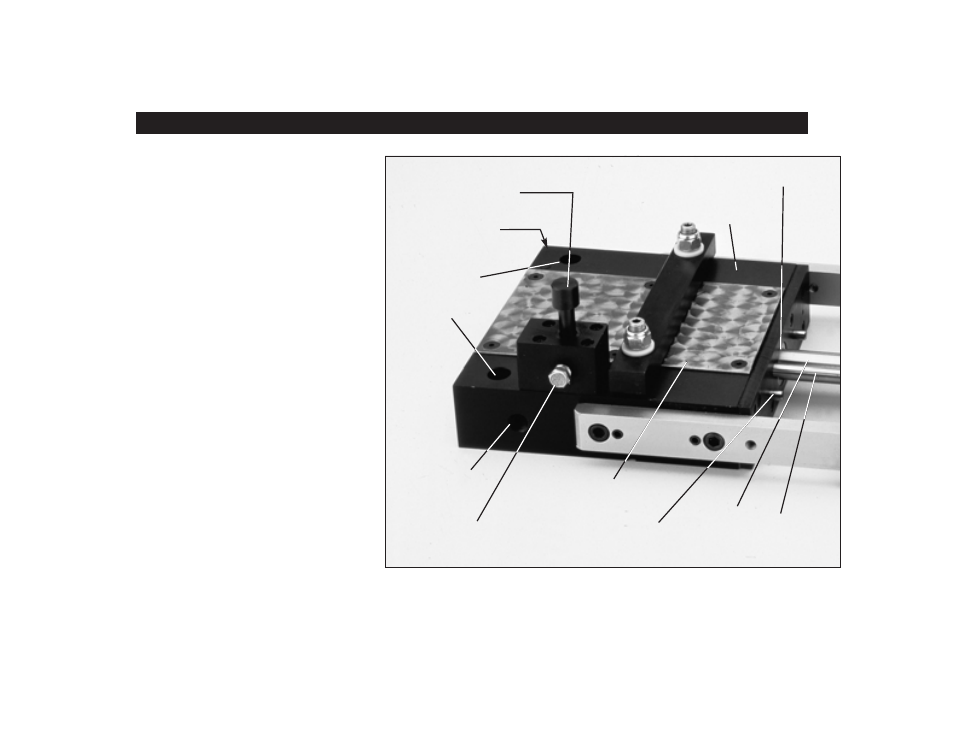

Modern Cup Wiper Seal (instead of “O” Rings) maintains

clean piston assembly and significantly increases cycle life

Body constructed of hard-coat

anodized, aircraft aluminum for weight

reduction and minimal wear characteristics

Actuating valve or optional

remote actuation controls feed

motion and clamp sequencing

Speed adjustment screw

controls feed head velocity

and material inertia

Two (or four) drilled

holes provide easy

mounting to die shoe,

bolster, or mounting

bracket

Oversized air inlet

eliminates air pressure

volume problems

Replaceable steel wear

plates protect feed surface

from material edges

Air silencers greatly

reduce noise to enhance

the operator’s environment

Two shock absorbers

automatically control feed

head and material inertia

Main piston

rod is hard

chrome plated

and ground

Twin

external air

tubes are

stainless steel.