Three pilot release methods – PA Industries Precision AirFeed User Manual

Page 16

14

THREE PILOT RELEASE METHODS

ADJUSTMENTS

For most pilot release applications, set the Feed Pitch

approximately .005" (.1mm) short and the Pilot

Release Stock Clamp will allow the pilot pin to pull the

material under the clamp pad into the proper position.

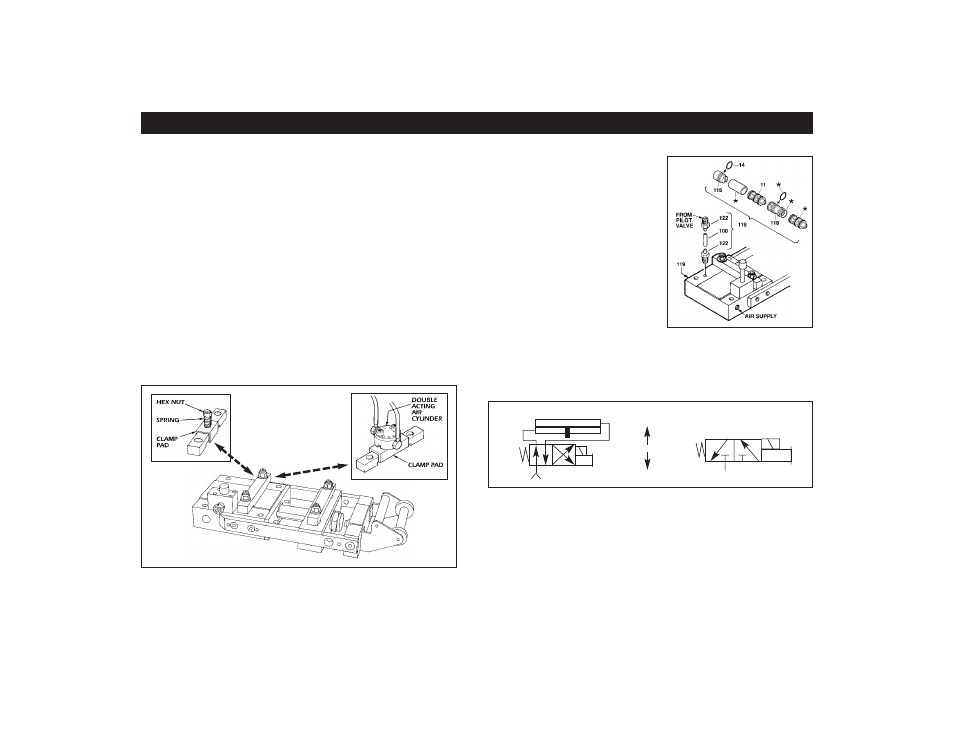

MECHANICAL PILOT RELEASE

The Mechanical Spring-Loaded Pilot Release Clamp

is installed in place of the standard Stock Clamp. Turn

the Hex Nut to compress the Spring for the desired

clamp and material pressure. Not available on LX.

PNEUMATIC PILOT RELEASE

The Pneumatic Pilot Release can be used for those

applications that require more sensitive clamping

pressure, or that the Clamp pad be completely free

of the material. With this system, the clamping

pressure may be adjusted by regulating the air

supply to the valve. The clamp pad is fitted with a

quick-response cylinder for positive stock grip and

release. Timing is controlled by an external 4-way

Solenoid valve or spool valve.

INTERNAL PILOT

RELEASE (IPR)

This internal valving system

provides up to 270 pounds

of clamping force with the

standard clamp and is

available on all FX, HX, and

LX models. The Internal Pilot

Release controls the release

of the Stock Clamp with a

timed air signal connected to

the 1/8" NPT port. This

feature gives you the option

of using pilot release, or not,without the downtime

necessary for changing clamps. One switch turns the

system on or off. The IPR requires an external 3-Way

Spool or Solenoid Valve.

*

ALREADY

INSTALLED

IN AIR FEED

AIR SUPPLY

EXHAUST

N.C. (STD)

PILOT

INTERNAL PILOT RELEASE

PNEUMATIC PILOT RELEASE

MECHANICAL

PILOT

RELEASE

PNEUMATIC

PILOT

RELEASE

IN

EX

CYLINDER

VALVE

S

AIR SUPPLY 120 PSI MAX. (8 BAR)

RELEASE

CLAMP