DE-STA-CO 115RSD User Manual

Page 9

its mating surface on center post (7).

18. Install shims (5) in housing (1).

19. Insert follower wheel (4) down through

opening of housing (1).

20. Install quad ring (27) in groove of output

bearing retainer (6).

21. Apply EXP 222 grease on quad ring (27)

and its mating surface on follower wheel (4).

22. Apply a bead of silicone around follower

wheel opening of housing (1).

23. Install shims (5) on housing (1).

24. Apply a bead of silicone under output

bearing retainer (6).

25. Install output bearing retainer (6).

26. Install screws (32) using Permabond thread

locking liquid as recommended in the

General Service Manual.

27. Wipe off all excess silicone.

OIL SEAL INSTALLATION

Install new oil seal as described in the General

Service Manual.

LUBRICATION

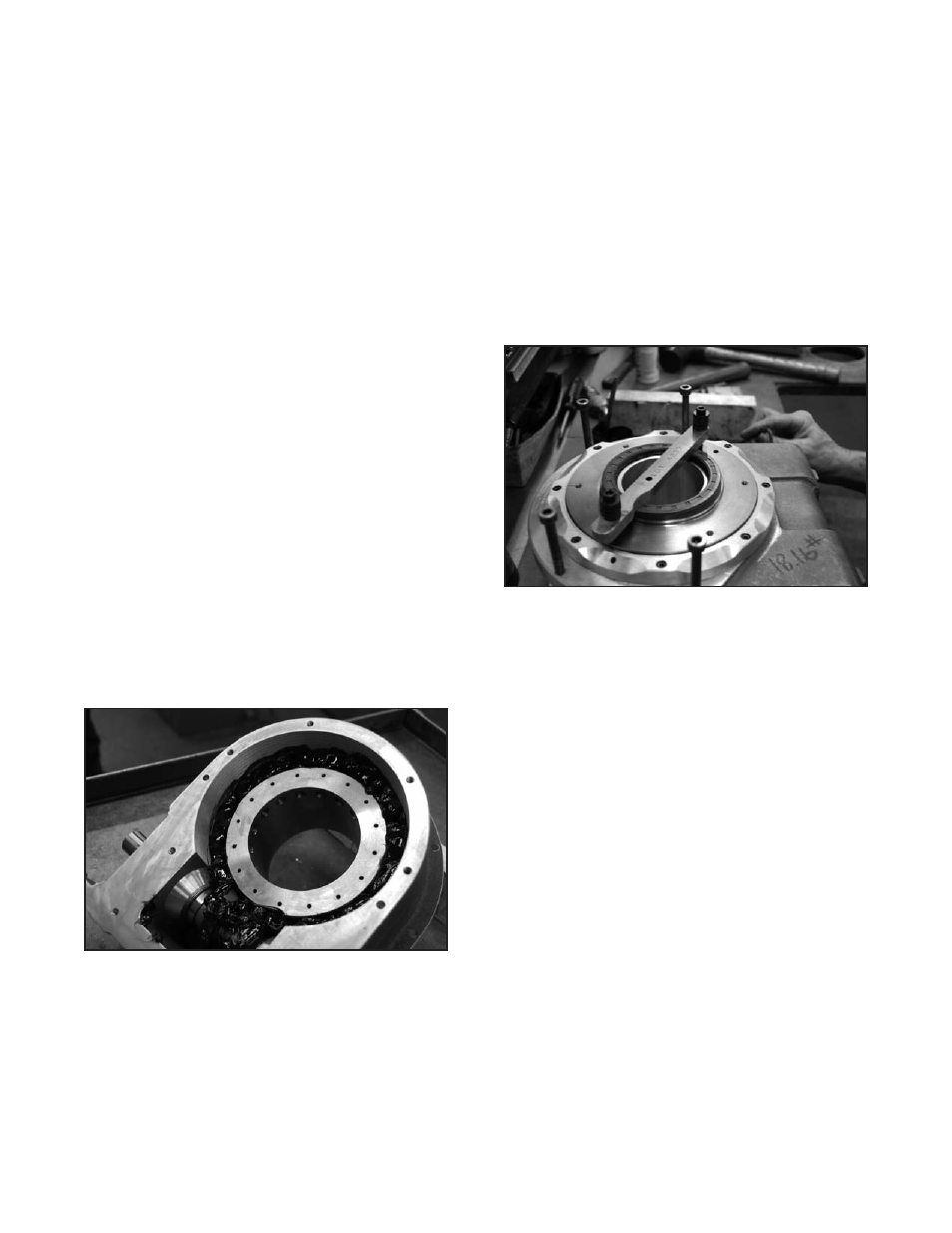

Fig.10Lubrication

With housing (1) upside down, fill housing with 16

oz. of EXP 222 grease, so that grease is level with

top of cam followers (25).

BOTTOM COVER INSTALLATION

A. Install two dowel pins (1b) in the cover for

alignment.

B. Apply a bead of silicone around bottom cover

opening of housing and install bottom cover.

C. Install screws (1a) using Permabond thread

locking liquid as recommended in the

General Service Manual.

SEAL INSTALLATION

Fig.11Sealinstallation

A. Apply EXP 222 grease to outside of seal

(9, 26).

B. Install seal around center post (7), taking

care to depress it evenly so that rubber seal

does not fold.

SERVO MOTOR INSTALLATION

A. Position clamp collar (13) on input shaft (15). The

collar should be positioned so collar screw will be

accessible through opening in mounting plate.

B. Position mounting plate and servo motor on

housing (1).

C. Working through opening in mounting plate,

tighten shaft collar screw (29).

D. Install motor mounting screws (23) using

Permabond thread locking liquid as

recommended in the General Service Manual.

8