Disassembly – DE-STA-CO 115RSD User Manual

Page 4

DISASSEMBLY

GENERAL

Remove all accessory equipment such as clutches,

reducers, and sprockets.

SERVO MOTOR REMOVAL

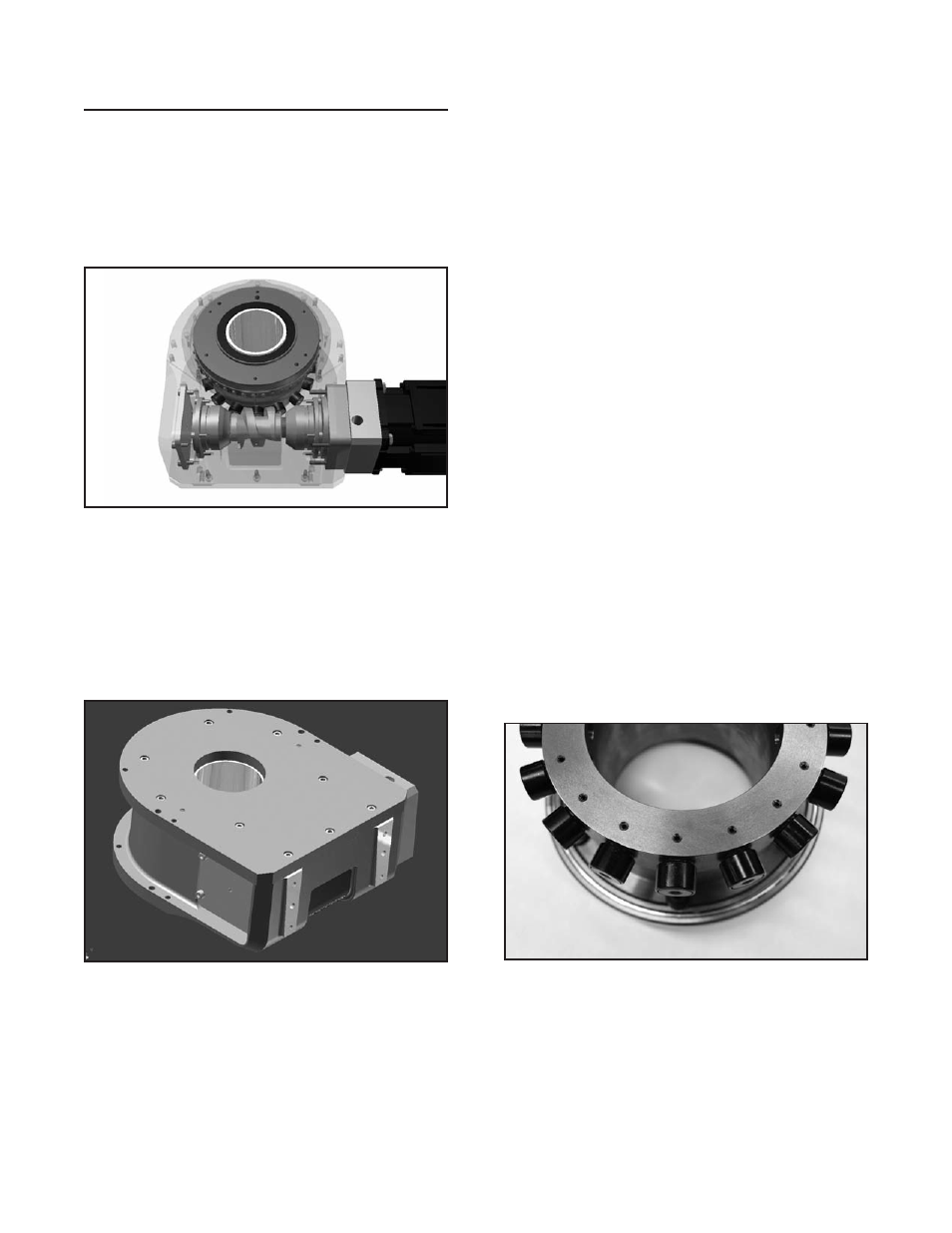

Fig.1Servomotorremoval

A. Loosen the screws (23) of servo motor

adapter (22).

B. Remove screws (23), servo motor, and shaft

collar (13) from input shaft.

BOTTOM COVER AND LUBE REMOVAL

Fig.2Bottomcoverandluberemoval

A. With housing (1) turned upside down,

remove screws (1a) and dowel pins (1b)

and bottom cover.

B. Flush entire unit with a solvent to remove grease

from cam compartment.

FOLLOWER WHEEL REMOVAL

A. Remove output bearing retainer (6) and shims (5)

from housing (1).

NOTE: Keep shims with retainer. You will be asked

to reinstall or replace with the same shim thickness

during assembly.

B. Remove quad seal (27) from output bearing

retainer (6).

C. Remove follower wheel (4) from housing (1).

D. Remove shims (5) from housing (1).

NOTE: Keep shims with follower wheel. You will be

asked to reinstall or replace with the same shim

thickness during assembly.

INSPECTION OF CAM FOLLOWERS

Inspect cam followers (25) for damage or radial

looseness. Looseness should not exceed 0.001

inch. Do not confuse radial looseness with axial

endplay. Endplay will be between 0.03 and 0.06 inch

as a normal condition. If it exceeds 0.06 inch, it may

require replacement.

NOTE: Generally, cam followers are replaced as

added insurance against eventual failure.

FOLLOWER REMOVAL

Fig.3Followerremoval

A. Apply heat to setscrews (31) and remove the

setscrews while still warm.

B. Turn the follower wheel (4) over to remove steel

balls.

C. Threaded holes have been provided in the ends

of the follower (25) for ease of removal. Use a

3