Assembly – DE-STA-CO 115RSD User Manual

Page 6

ASSEMBLY

PRIOR TO ASSEMBLY

A. Clean and deburr all parts before reassembling.

B. Follow tightening torque and Permabond

recommendations as outlined in the General

Service Manual.

INPUT SHAFT/CAM REASSEMBLY

Fig.5Inputshaft/camreassembly

A. Apply anti-seize lubricant to the end of the shaft

(15) with the smaller diameter.

B. Heat cam (16) to 250 degrees prior to installation.

C. Place cam (16) on an arbor press and press shaft

(15) in until bottomed.

D. Place cam (16) on its side until cool to the touch.

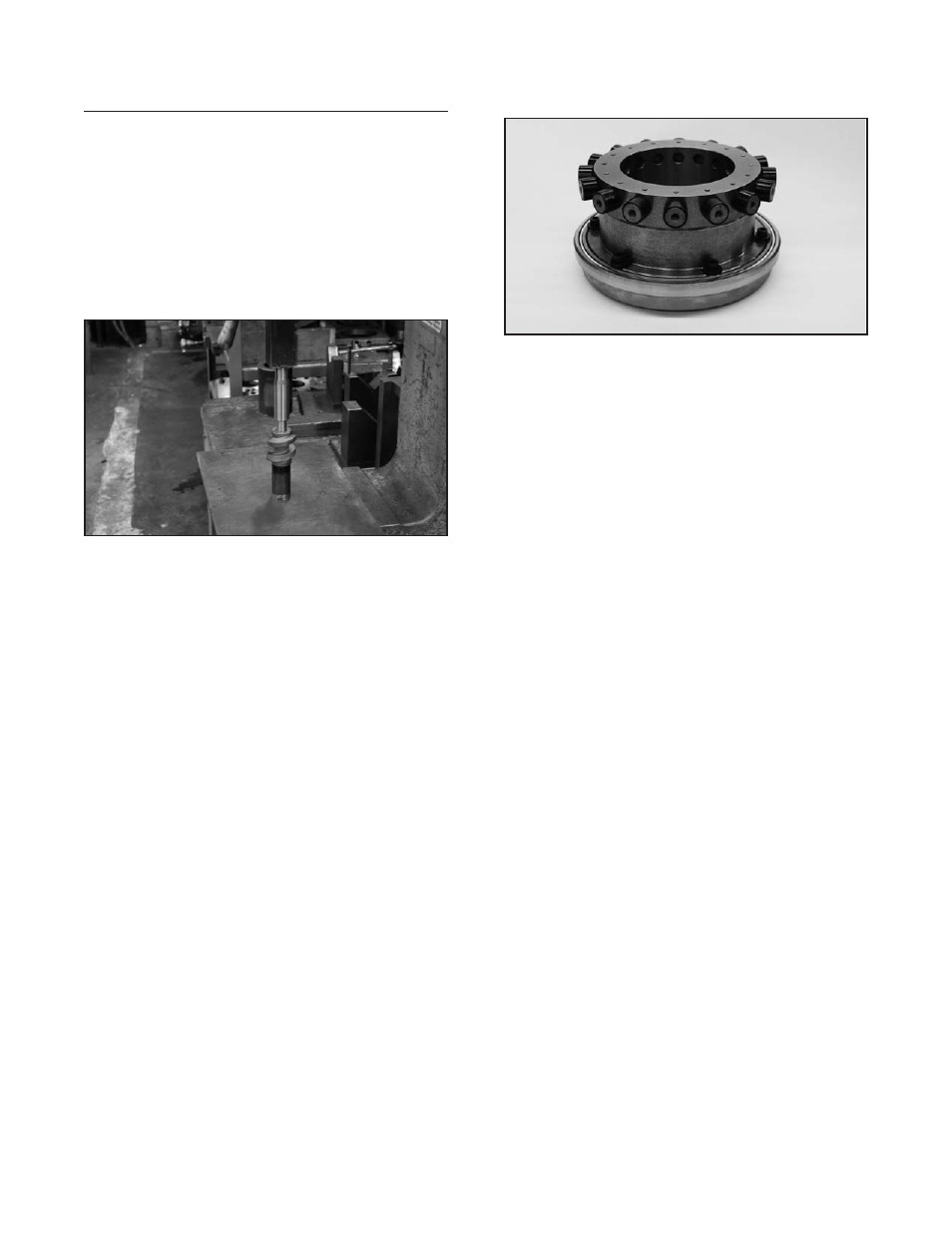

FOLLOWER WHEEL REASSEMBLY

Fig.6Followerwheelreassembly

A. Apply anti-seize lubricant to both follower wheel

(4) and bore of the bearing (3).

B. Using an arbor press and adaptor fixture, press

bearing (3) onto the follower wheel (4) until it is

seated. Heat may be applied to bearing if necessary.

C. Check cam followers (25) to make sure they

spin freely.

D. Install capscrews (28) with washers (24) using

Permabond thread-locking liquid adhesive as

recommended in the General Service Manual.

CAUTION:Besuretopressthefollowerinstraight,

asdamagetothefollowerandfollowerwheelcould

occurifimproperlyalignedduringinstallation.

E. Use these steps to install the cam followers:

1. Remove shipping o-ring from the stud of cam

follower (25). This o-ring is used only to hold

cam follower together.

2. Apply anti-seize lubricant to holes in follower

wheel (4).

3. Cam followers require use of an insertion

gage CAMCO Part Number 99A73565000000

for proper installation.

a. Place insertion gage CAMCO Part

Number 99A73565000000 around cam

follower (25).

b. Press cam follower (25) onto follower

wheel (4) to the position prescribed by the

gage. If pressed too far, the follower will

not turn freely.

4. Install setscrews (31) using Permabond

thread-locking liquid as recommended in the

General Service Manual.

5. Install remaining followers (25) in the

same manner.

5