DE-STA-CO 115RSD User Manual

Page 7

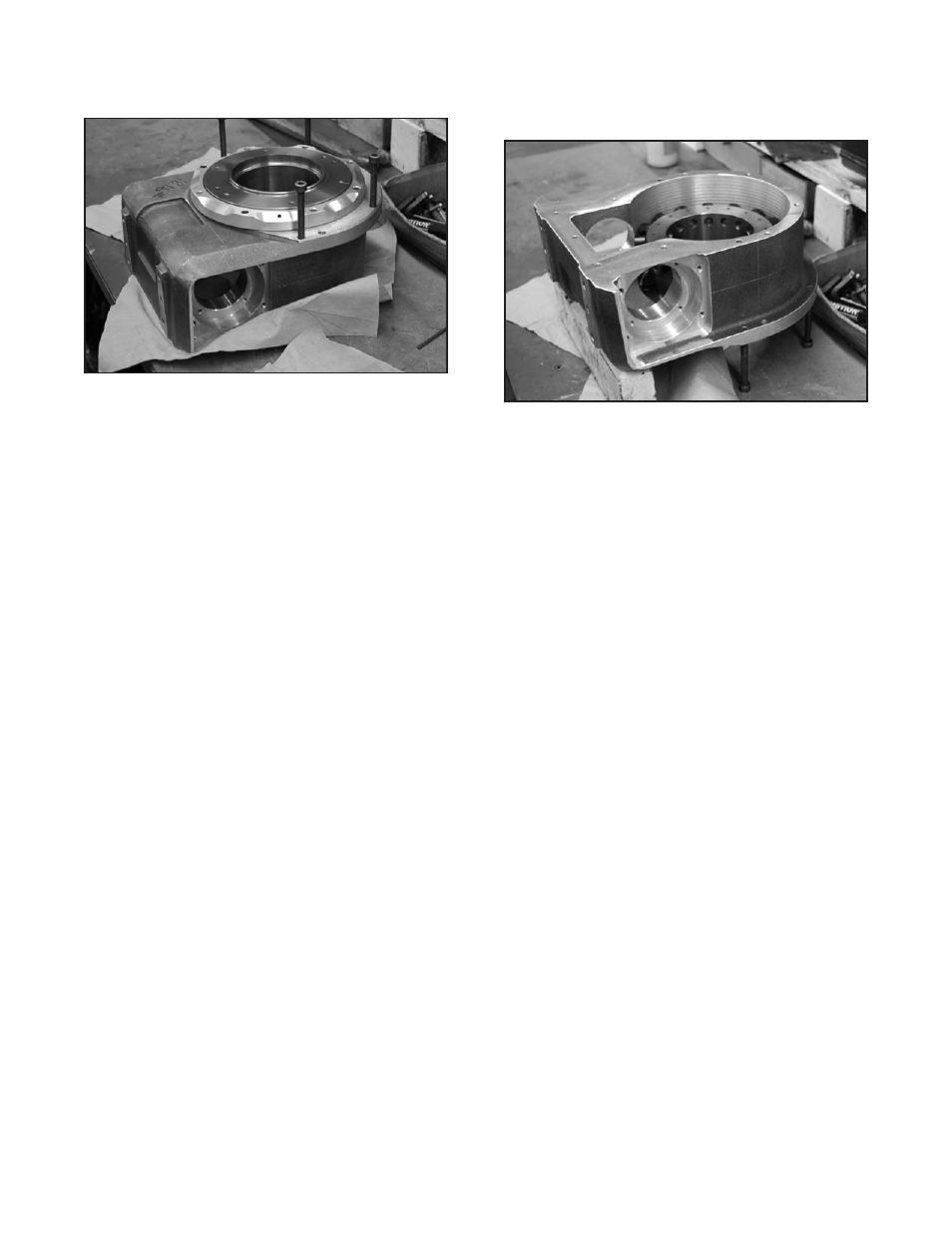

FOLLOWER WHEEL INSTALLATION

Fig.7Followerwheelinstallation

A. Loosen either cartridge (11, 12) so that follower

wheel (4) has a small amount of play.

B. Position housing (1) on a work bench with

opening for cover facing up. Create temporary

legs with screws to hold housing.

C. Install shims (5) in housing (1). It is preferable to

install the same shims that were removed from

the housing during disassembly; if that is not

possible, use shims of equivalent thickness.

D. Insert follower wheel (4) down through opening of

housing (1).

E. Apply a bead of white silicone on the surface

where output bearing retainer (6) will rest.

F. Install output bearing retainer (6) with shims (2). It

is preferable to install the same shims that were

removed during disassembly; if that is not

possible, use shims of equivalent thickness.

G. Install and tighten capscrews (29a).

H. Tighten cartridges (11,12).

BEARING CARTRIDGE REASSEMBLY

A. Coat the outside of bearing and bore of the

bearing cartridges (11, 12) with anti-seize

lubricant.

B Using an arbor press, install bearing into bearing

cartridges (11, 12). The rounded edge of bearing

should be pressed into cartridge.

SETTING INPUT SHAFT/CAM

BEARING PRELOAD

Fig.8Settinginputshaft/cambearingpreload

A. Position housing (1) on a work bench with

opening for bottom cover facing up. Create

temporary legs with screws to hold housing.

B. Apply EXP 222 grease to bearings

(18, 19, 20 and 21).

C. Install first cartridge (11) into the same side and

position as disassembled. It is preferable to

install the same shims that were removed during

disassembly; if that is not possible, use shims of

equivalent thickness.

D. Install and tighten screws (29a).

E. Insert input shaft (15) into housing (1) so that

shaft orientation is the same as before

disassembly.

F. Apply EXP 222 grease in bearing.

G. Install second cartridge (12) in the same position

as disassembled. It is preferable to install the

same shims that were removed during

disassembly; if that is not possible, use shims of

equivalent thickness.

H. Install and tighten screws (29a).

I. Rotate shaft (15) and check preload. There should

be no endplay and a small amount of drag should

be felt from preloading bearings—add or remove

shims (14) as necessary to obtain this condition. In

rare instances, it may be necessary to machine the

cartridge if all shims have been removed and

endplay still exists.

NOTE: The same amount of shims should be added

or removed from both cartridges.

6