Frequently asked questions cont’d, General information, Dimensional data – BRAND Hydraulics LS DIRECTIONAL CONTROL VALVES User Manual

Page 2: Flow & pressure information

04/14

7

.2

9

"

[1

8

5

.2

]

0

.7

1

"

[1

8

.1

]

0.25" [6.4]

0.25" [6.4]

8.55" [217.1]

1

.0

0

"

[2

5

.4

]

2

.4

4

"

[6

2

.0

]

1

.0

6

"

[2

6

.9

]

2

.1

2

"

[5

4

.0

]

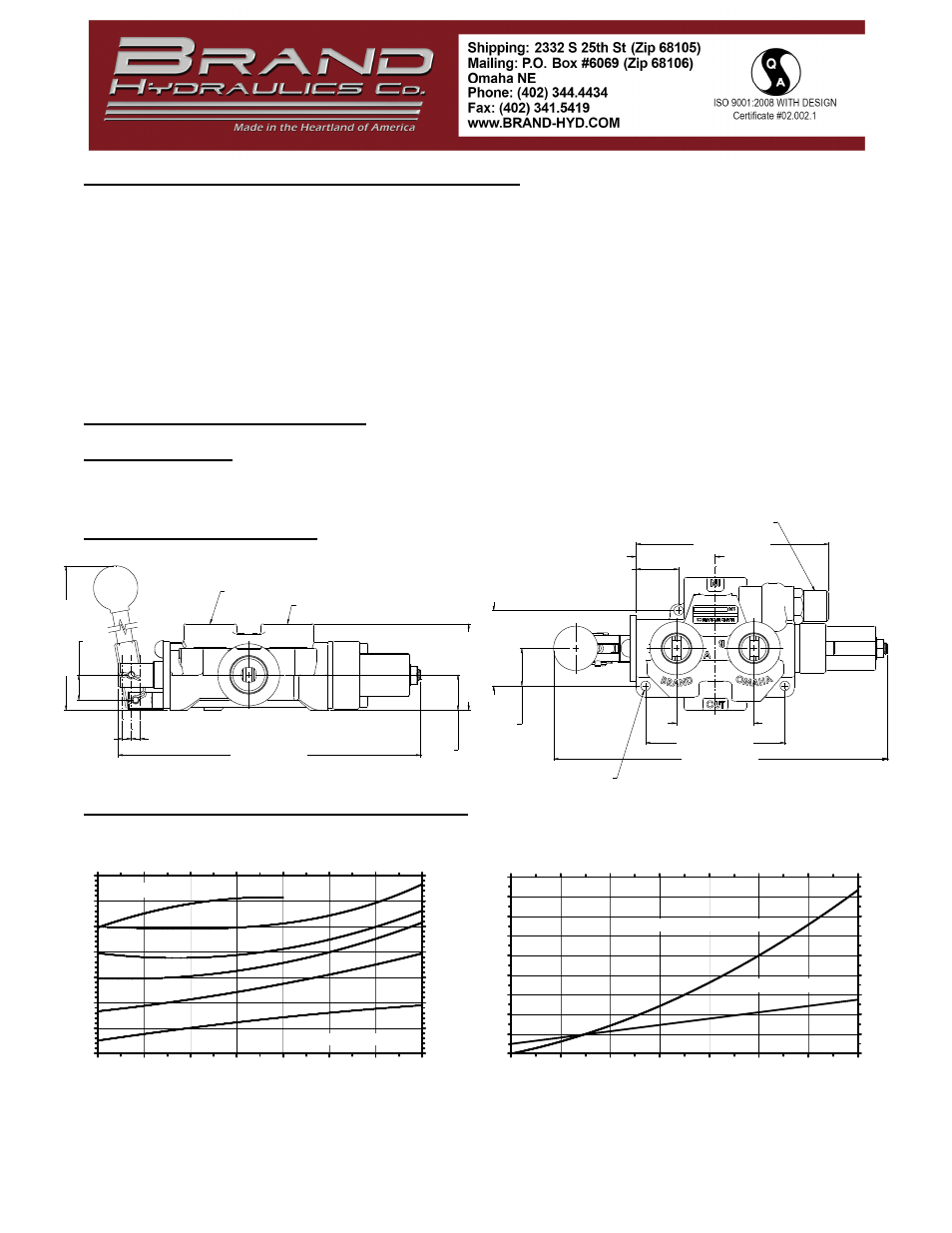

3.94" [100.0]

1.20" [30.6]

2.24" [56.8]

5.44" [138.2]

9.42" [239.2]

ADJUSTABLE RELIEF (2000 PSI (138 BAR) FACTORY SETTING)

2.19" [55.5]

B PORT

A PORT

3X Ш0.27" [Ш6.7]

Pressure vs. Flow for LS Relief (R)

0

500

1000

1500

2000

2500

3000

3500

1.0

3.0

6.0

9.0

12.0

15.0

18.0

20.0

Flow (gpm)

P

re

s

s

u

re

(

p

s

i)

0.0

34.5

68.9

103.4

137.9

172.4

206.8

241.3

3.8

11.4

22.7

34.1

45.4

56.8

68.1

75.7

Flow (lpm)

P

re

s

s

u

re

(

b

a

r)

B505 Spring

Relief is set at 6 gpm

Pressure Drop vs. Flow

0

5

10

15

20

25

30

35

40

45

1.0

3.0

6.0

9.0

12.0

15.0

18.0

20.0

Flow (gpm)

P

re

s

s

u

re

D

ro

p

(

p

s

i)

0.0

0.3

0.7

1.0

1.4

1.7

2.1

2.4

2.8

3.1

3.8

11.4

22.7

34.1

45.4

56.8

68.1

75.7

Flow (lpm)

P

re

s

s

u

re

D

ro

p

(

b

a

r)

P to A or B, and A or B to T

Neutral Flow (T4 Spool)

FREQUENTLY ASKED QUESTIONS cont’d:

Q: Can I paint the valve?

A: Painting valves is acceptable as long as the following precautions are taken:

1- All ports must be plugged

2- Spool must be masked or taped off completely.

Any paint on the spool will cause leakage when it chips off. Warranty is void if any valve is returned with paint on

the spool.

Q: What is the typical use of the “Hydraulic Kick-out”?

A: The typical set-up for using hydraulic kick-out is the retraction of a log splitter cylinder. In this case, the cylinder can

retract unmanned while another log is being loaded onto the splitter.

GENERAL INFORMATION:

Pipe Thread Sealant - Warranty is void when Teflon tape is used to seal pipe threads. This is because Teflon tape is a

friction reducing agent which allows customers to over-torque fittings. We recommend using a sealant that does not include

friction reducing agents i.e. Lead Plate.

DIMENSIONAL DATA:

FLOW & PRESSURE INFORMATION: