Spool schematics, Safety precautions – BRAND Hydraulics DCF DIRECTIONAL CONTROL VALVE User Manual

Page 3

04/14

T

P

A

B

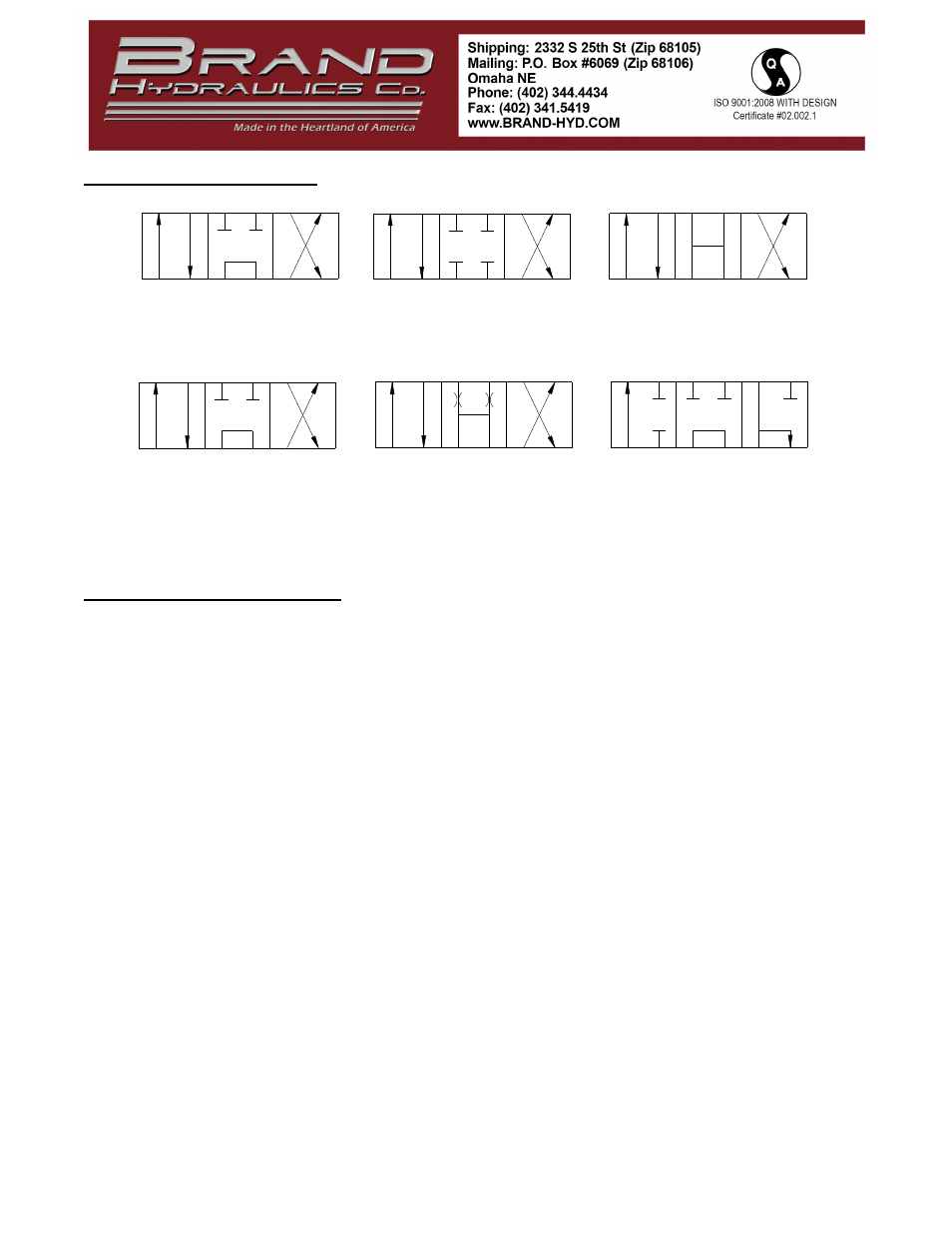

Tandem Center (T) - Powers cylinder or motor in

both directions (metering capability is very

limited). Pump unloads to tank when spool is in

neutral. Cylinder or motor blocked when spool in

neutral. This spool is not designed for DCF valve.

Open Center (O) - All of the ports are connected

to tank when the spool is in neutral. Allows

cylinder to move or motor to rotate when spool is

in neutral. This spool is not designed for DCF

valve.

Fine Metering Spool (M) - The pressure drop in

neutral is higher then the (TM) spool. Requires

external locking valves to hold cylinder, because

ports A and B are open (orificed) in the neutral

position. Extremely fine metering control. This

spool is designed for the DCF valve and acts as

closed center in DC valve.

B

A

P

T

B

A

P

T

Tandem Metering Spool (TM) - Similiar to (T)

spool except much finer metering control. The

pressure drop in neutral is lower then the (M)

spool. Cylinder or motor blocked in neutral and

pump unloads to tank. This spool is designed for

DCF valve.

P

T

A

B

Tandem Three Way (T3) - Powers the cylinder in

one direction. Pump unloads to tank when spool

is in neutral, or when spool is being reversed.

Cylinder is blocked when spool is in neutral. Port

"B" is plugged. This spool is designed for the DC

valve.

P

T

Closed Center (C)- All ports are blocked in

neutral. Blocks cylinder or motor in neutral.

Required for use with pressure compensated

pump. This is not available for DCF valve.

A

P

A

B

T

B

SPOOL SCHEMATICS:

SAFETY PRECAUTIONS:

It is the purchaser’s responsibility to determine the suitability of any Brand Hydraulics Co. product for an intended

application, and to ensure that it is installed in accordance with all federal, state, local, private safety and health

regulations, codes and standards. Due to the unlimited variety of machines, vehicles and equipment on which our

products can be used, it is impossible for Brand Hydraulics Co. to offer expert advice on the suitability of a product

for a specific application. It is our customer’s responsibility to undertake the appropriate precautions, testing and

evaluation to prevent injury to the end-user.

Overpressure may cause sudden and unexpected failure of a component in the hydraulic system, resulting in serious

personal injury or death. Always use a gauge when adjusting a relief valve.