Carlon Expansion Joints for PVC Rigid Nonmetallic Conduit User Manual

Page 4

Setting Expansion Joint for Temperature

When a more precise calculation for expansion is needed,

it can be calculated as follows:

1.

You must determine the maximum temperature range. This is done by subtracting the lowest

temperature you anticipate from the highest temperature you anticipate.

Example: Let’s say in winter, we expect the temperature to get down to -10°F and in the summer, we

expect the temperature to get as high as 110°F. The maximum temperature range is 110 -(-10) = 120°F.

2.

The length of run between fixed points must be determined.

Let’s assume 90 feet for this example.

3.

The total expansion change can be calculated as follows:

Total expansion change in inches = (coefficient of thermal expansion) x (maximum temperature range)

x (length of run in inches).

Example: Total expansion change = (3.38 x 10

-5

in./in./°F) x (120˚F) x (90ft x 12in./ft) = 4.38 in.

Thus, travel can be covered with one 6 inch expansion joint.

4.

The “set position” can be determined from the following example.

Example: If the temperature at installation was 65°F, the difference from maximum is 110°F- 65°F = 45°F.

Use ratio: (difference from maximum) / (Total expected range) = 45/120 = .375 in.

(0.375) x 6 inch travel = 2.25 in.

The piston at 65°F would retract 2.25 inches.

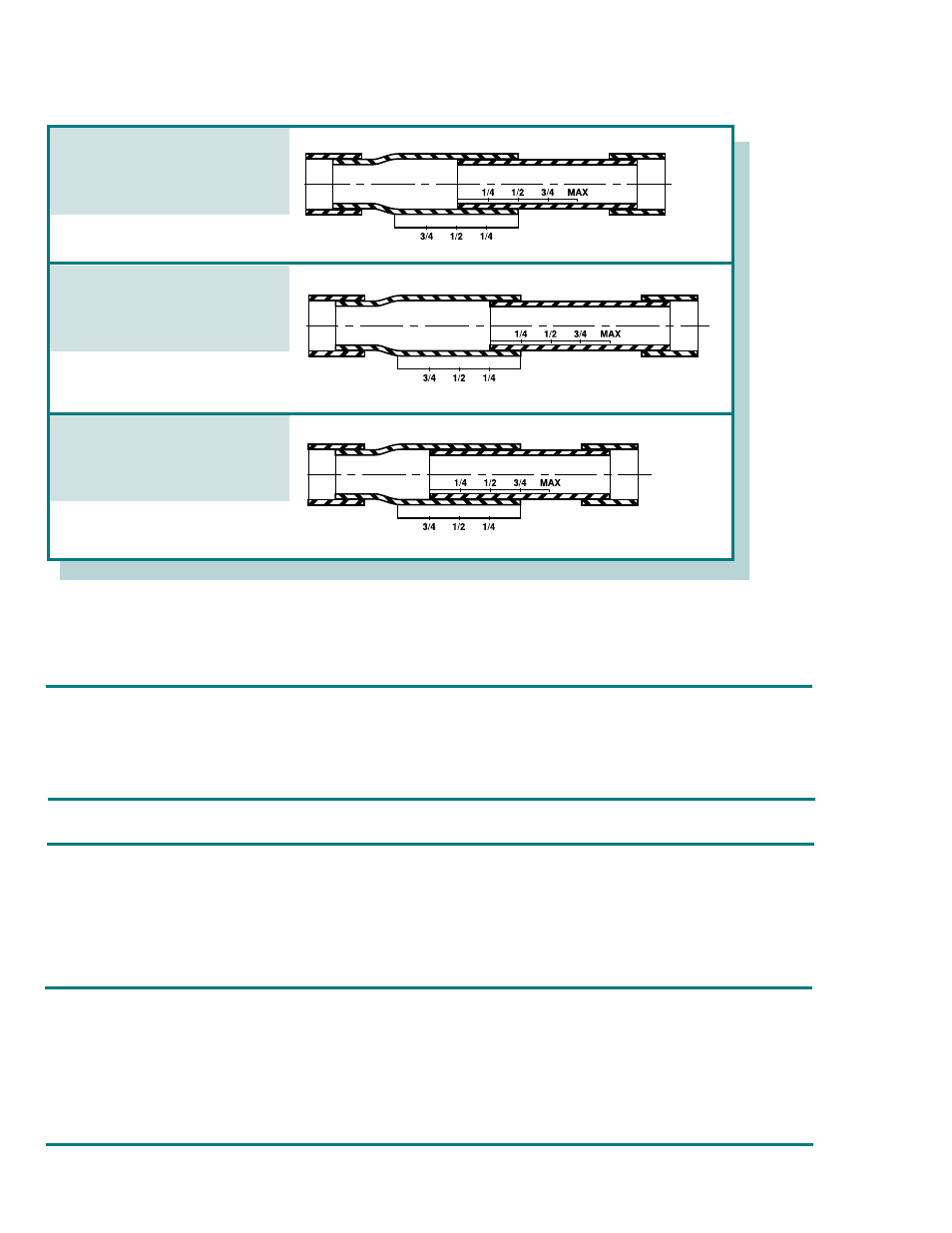

A.

For medium temperature

(65˚ - 75˚ F) set piston

1

/

2

way in barrel.

B.

For cold temperature

(20˚ - 30˚ F) set piston

1

/

4

way in barrel.

C.

For hot temperature

(95˚ - 105˚ F) set piston

3

/

4

way in barrel.

Gross Automation (877) 268-3700 · www.carlonsales.com · [email protected]