Features – Atec Wallace-Tierman-65-120 User Manual

Page 2

Features

2

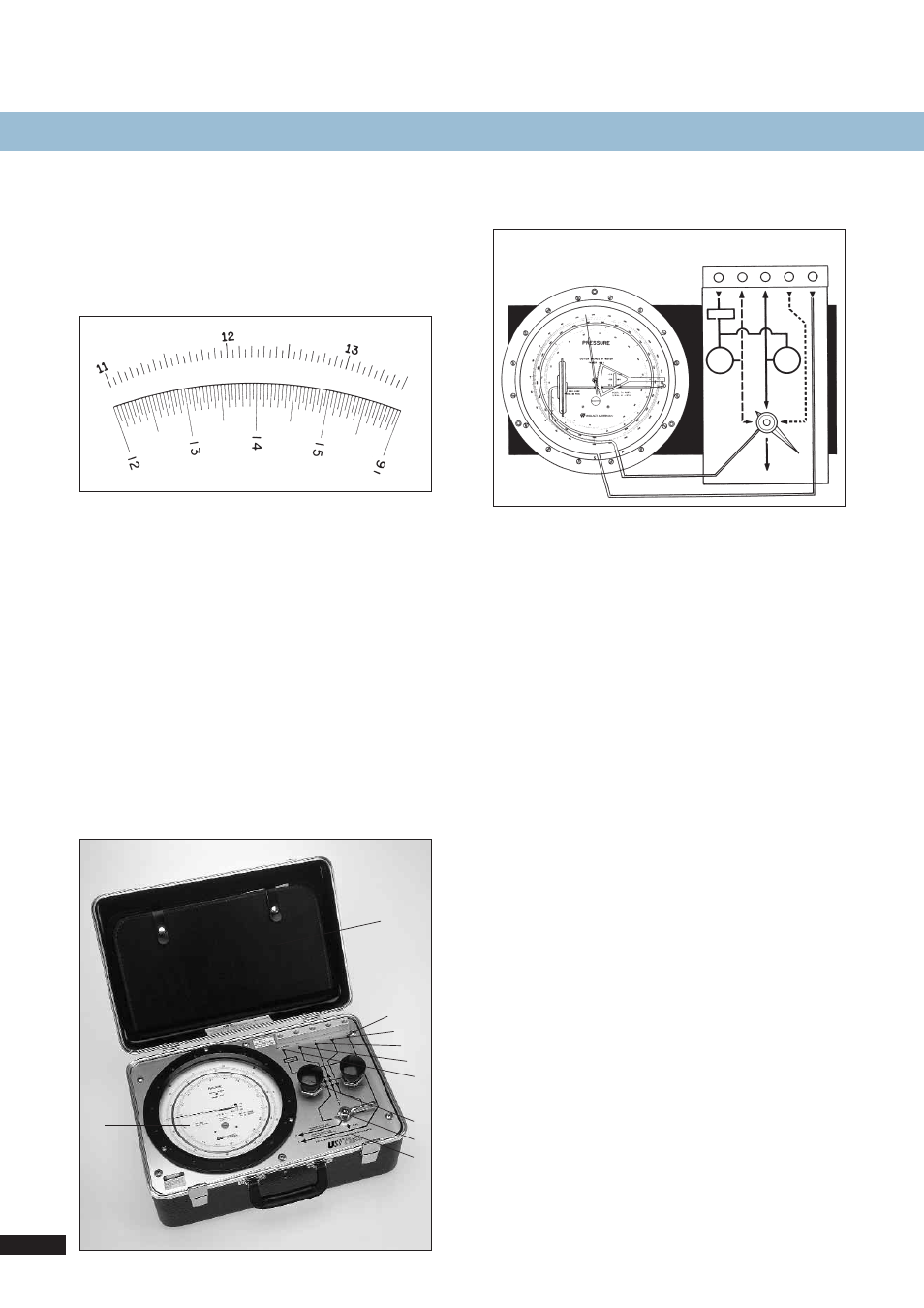

Clear, Accurate Readout

Sharply defined graduations, a 45-inch (1140 mm) scale length

over two pointer revolutions, and a knife-edge pointer facilitate

precise readouts. All scale calibrations are individually plotted

and hand marked to produce a dial custom fitted to the pres-

sure element and mechanism of that gauge.

Connections for different Pressure readouts

For gauge pressure:

test pressure is applied to the capsule through the appropriate

P connection; the case is open to atmosphere through S.

For differential pressure:

high test pressure is applied to the capsule through the appro-

priate P connection. Low test pressure is applied to the case

through S.

For absolute pressure:

test pressure is applied to the capsule through the appropriate

P connection and the case is continuously subjected to full

vacuum through S.

For vacuum:

the capsule is open to atmosphere through connection P; the

case is connected to test vacuum at S.

For positive and negative pressures:

test pressure is applied to the capsule through the appropriate

P connection and the case is open to atmosphere through S.

Engineered for perfomance

The gauge housing is heavy cast aluminum with a tempered

glass dial cover. A built-in pressure-relief valve has a dumping

capacity which protects the case against overpressures to 10

times the maximum pressure rating. A separate pressure-relief

valve protects the capsule mechanism. The gauge is mounted

inside the carrying case on rubber-padded shock mounts. The

carrying case is constructed of strong but lightweight molded

ABS that flexes to absorb shock from impact.

Compact, built for on-site service

The W&T Portable Pneumatic Calibrator weights only 20 lb

(9 kg) and is only slightly larger than a attache case. The easy

portability, simple set-up, and the versatile capabilities of this

unit extends its usefulness for service in the field. Its portability

saves the time and expense of shop calibration.

W&T (top) and competitive scales of the same range.

Dif

f

Input

Input

to be

Read

Regulated

Output 2

Regulated

Output 1

Air

suppl

y

Filter

Reg.

Reg

.

P

1

P

2

P

3

S

P

1

P

2

P

3

Vent

1

2

3

4

5

6

7

8

9

10

1

Compartment for accessories

2

Differential Input

3

Input to be read

4

Regulated output no. 2

5

Regulated output no. 1

6

Air supply connection

7

Regulators

8

Selector Valve

9

Schematic flow diagram

10

Shock-mounted gauge