Vibrating test tables – Atec Vibco-Vibrating-Tables User Manual

Page 6

6

• Simulate Handling &

Transportation Shocks

• Verify Integrity of Electric Circuits

• Removes Dangerous Residue

• Detect Marginal Connections

VIBRATING TEST TABLES

VIBRATING TEST TABLES

Heavy duty all welded

construction

VIBCO’s test tables result in savings on manufacturing costs, increased product reliability and greater customer con-

fidence by detecting future failures right in your own plant, prior to shipment. Defective electrical components and

connections fail under the induced vibration, helping you to quickly identify the problems. This eliminates embarrass-

ing and costly repair and difficult tracing of circuits in the field. The simulation of transportation and handling shocks,

on the Vibco test table give the added advantage of showing up the defective solder joints, marginal connections and

faulty components.

Forces generated will not, however, effect components of sound integrity../ the vibration also removes potentially

harmful residue such as pigtail clippings, solder splashes and other debris lodged in the chassis. Vibco’s test tables

are also extensively used in fatigue testing of many, varied electronic and space industry products, including: radios,

TVs, military hardware, lights, computers, etc.

Over 40 years of vibration know how enables us to “tailormake” a vibrating table to fit your needs as to size, force,

frequency and amplitude. Consult our Engineering department.

PATENTED “LIVE-TOP” TABLE

Exclusive Vibco design assures full and even vertical vibration in all areas of the table top. This enables the quality

control station to utilize the full potential of the available working area. Quality control can now standardize test pro-

cedures now that consistency of testing and reliability of results is assured. Vibco’s wide choice of variable frequency

and constant frequency equipment gives you the ultimate in low cost product liability testing.

SPECIFICATIONS

Model US-900, 10000 VPM (*vibrations per minute - speed will vary with load) adjustable eccentrics with 3 force set-

tings at 10000 VPM Setting 1, 600 lbs. of centrifugal force; Setting 2, 950 lbs.; and Setting 3, 1100 lbs., 3.5 amps;

115 volt will handle test pieces up to 125 lbs. Model US-1600, 9000 VPM*, 3 force settings, 1100, 1600, 1900 lbs.,

4 amps 115 volt will handle test pieces up to 200 lbs.

• Stop Costly Field Service Calls

• Handles both Sub-Assemblies &

Complete Chassis

• Safe! No Harm to Sound Circuits

• Inexpensive Full Range Control

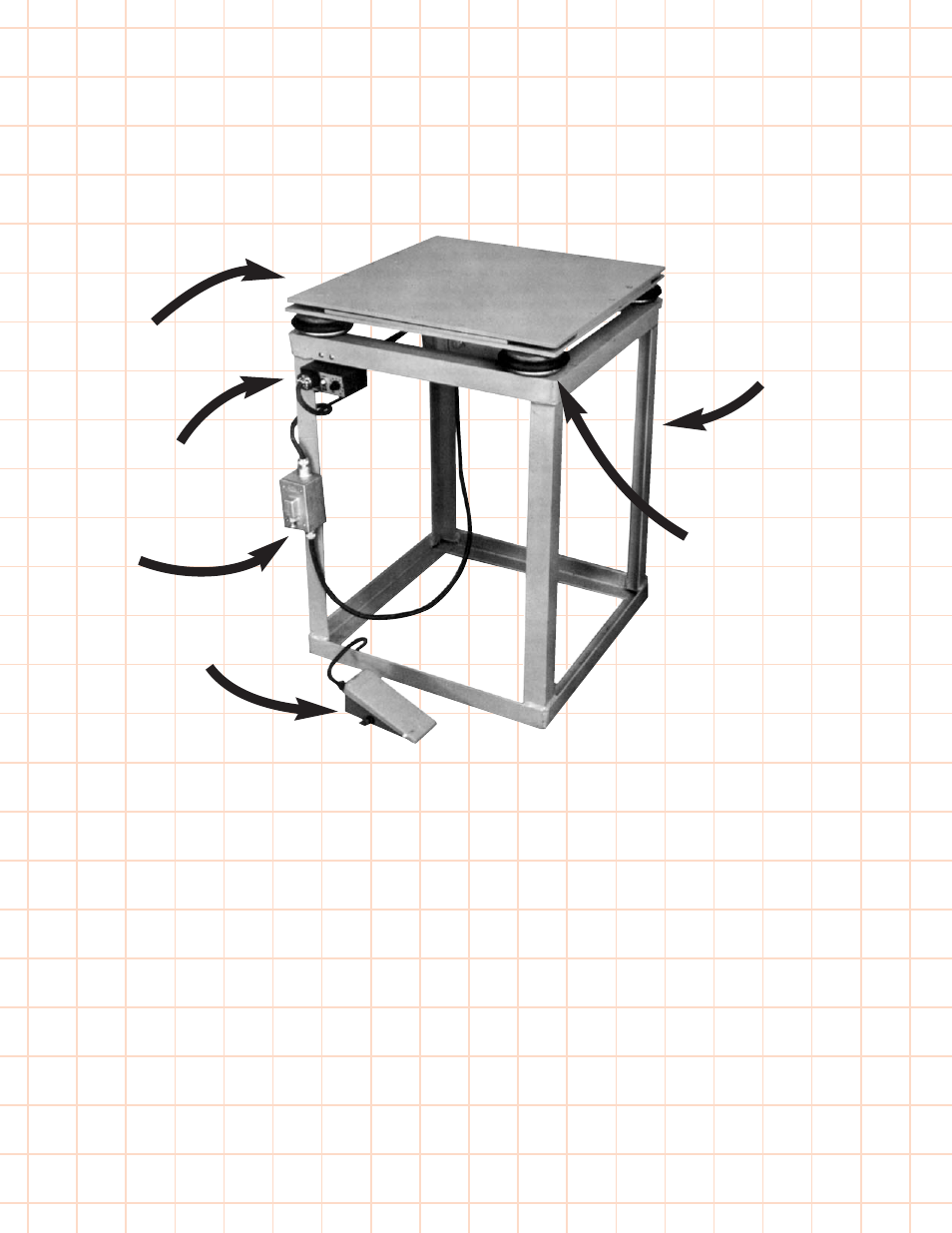

Inflatable rubber

shocks for almost

100% vibration

isolation

Patented “Live-Top”

Variable Speed Control

Overload Protection

On-Off convenient foot

switch

TABLE MODEL US-RD

24” x 24” x 36” High