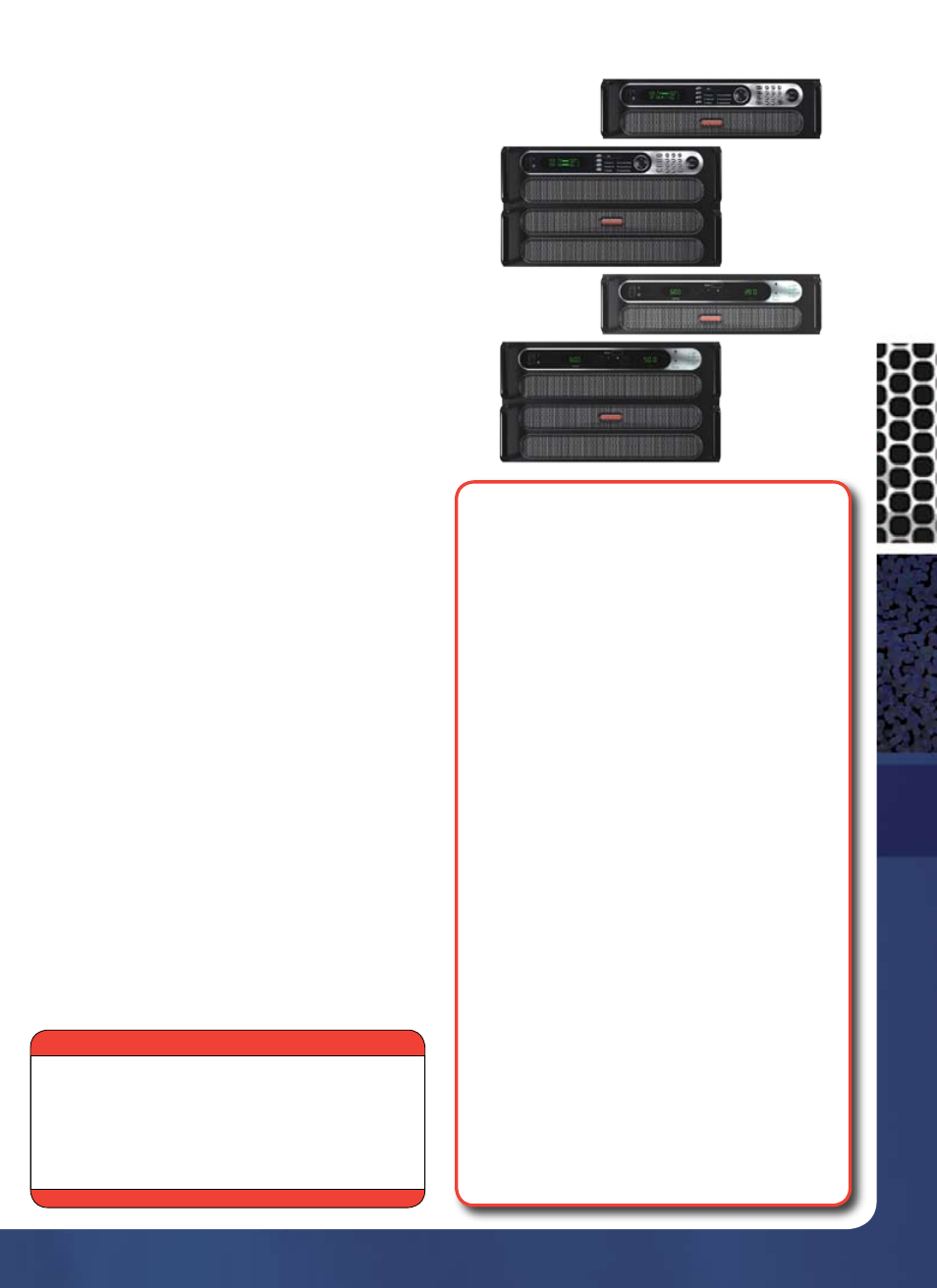

Applications and key features, Key features – Atec Sorensen-SG Series User Manual

Page 3

Applications

Process Control

Whether you are controlling ion beams for the manufacture of

semiconductors, or driving a current through electrolyte for precise

control in a plating process, the SG series is an ideal choice with it’s

small size, reliable modular design and standard analog programma-

bility. Direct control of V and I along with monitoring of the actual

voltage and current, provides a simple interface for your PLC or

other type of analog controller.

Product Development

Testing & Burn-in of DC-DC converters, laser diodes, automotive and

semiconductor components and aircraft flight hardware are just a few

of the items being tested using the SG product family. From simple

front panel control to complex test sequences for compliance testing,

the SG series will keep pace with your changing application needs.

Research

A research environment presents some of the most demanding

requirements on your test instrumentation. Equipment that is

sufficient today, may not meet the needs of the next project. With

the SG series this is no longer a problem. The modular design

allows you to easily upgrade to higher power levels in the future,

or parallel units to achieve up to 150 kW. With the sophisticated

sequencing capability of the SGI model, you can build an infinite

variety of test or diagnostic programs and have them execute

directly from the power supply.

Automotive Component Test

The 16-bit resolution and Ethernet enabled hardware triggering

allows for detailed sequencing associated with battery fluctuation

simulation. The tight load regulation capability of the SG series

makes it a superior source for validation and acceptance testing

and burn-in of automotive components. The 40V models, in

particular, provide a full range of testing to simulate battery

conditions. Margin testing of components, such as electronic control

units (ECU) and electromechanical components, is easily achieved.

Rackmount ATE Systems

The high power density of the SG series makes it ideal for

ATE System integration. The wide variety of voltage and current

combinations in 3U and 6U heights allows multiple voltage outputs

in a small amount of space. The wide variety of control methods

possible, allows easy integration into legacy systems as well as high

speed systems.

Battery Charging

The SG series provides high accuracy voltage output to optimize

battery charging. Battery charging requires high accuracy voltage and

stable current output. With the remote interface options, the charging

process can easily be automated for volume production.

Key Features

•

High Power Density: Up to 15 kW in a 3U / 30 kW

in a 6U chassis

•

Wide Voltage Range: 0-40V up to 0-600V, in

increments of 5 kW from 5 to 30 kW

•

Fast Load Transient Response: Protection from

undesired voltage excursions

•

Low Ripple and Noise: Suitable for the most

sensitive applications

•

Parallelable up to 150 kW: Expandable as your

requirement grows

•

Modular Design: Upgradeable for the ultimate in

investment protection.

•

Sequencing: Program custom waveforms

•

Easy-to-read Fluorescent Display: SGI supports

English, French, German, Italian, Spanish, Chinese,

Japanese, and Korean languages

•

16-bit Resolution: Optional IEEE-488.2 + RS-232C

or Ethernet provides precise control

•

Ethernet Control: LXI Class C compliant

communication with integrated web server

•

Direct Relay Control: Control output and sense

isolation relays, along with polarity relays. (Ethernet

Option Only)

•

Hardware Trigger: Ethernet Option Only

•

5 Year Warranty

Burn-In

Compliance Testing

Materials Research

Process Control

Product Validation

Automotive Electronics

Rackmount ATE Systems

Battery Charging

See the SFA product brochure for very high current slew

rate and low stored energy applications.

Applications