Ge sensing – Atec Panametrics-Olympus-DF868 User Manual

Page 7

GE

Sensing

DF868

Application

Notes In Brief

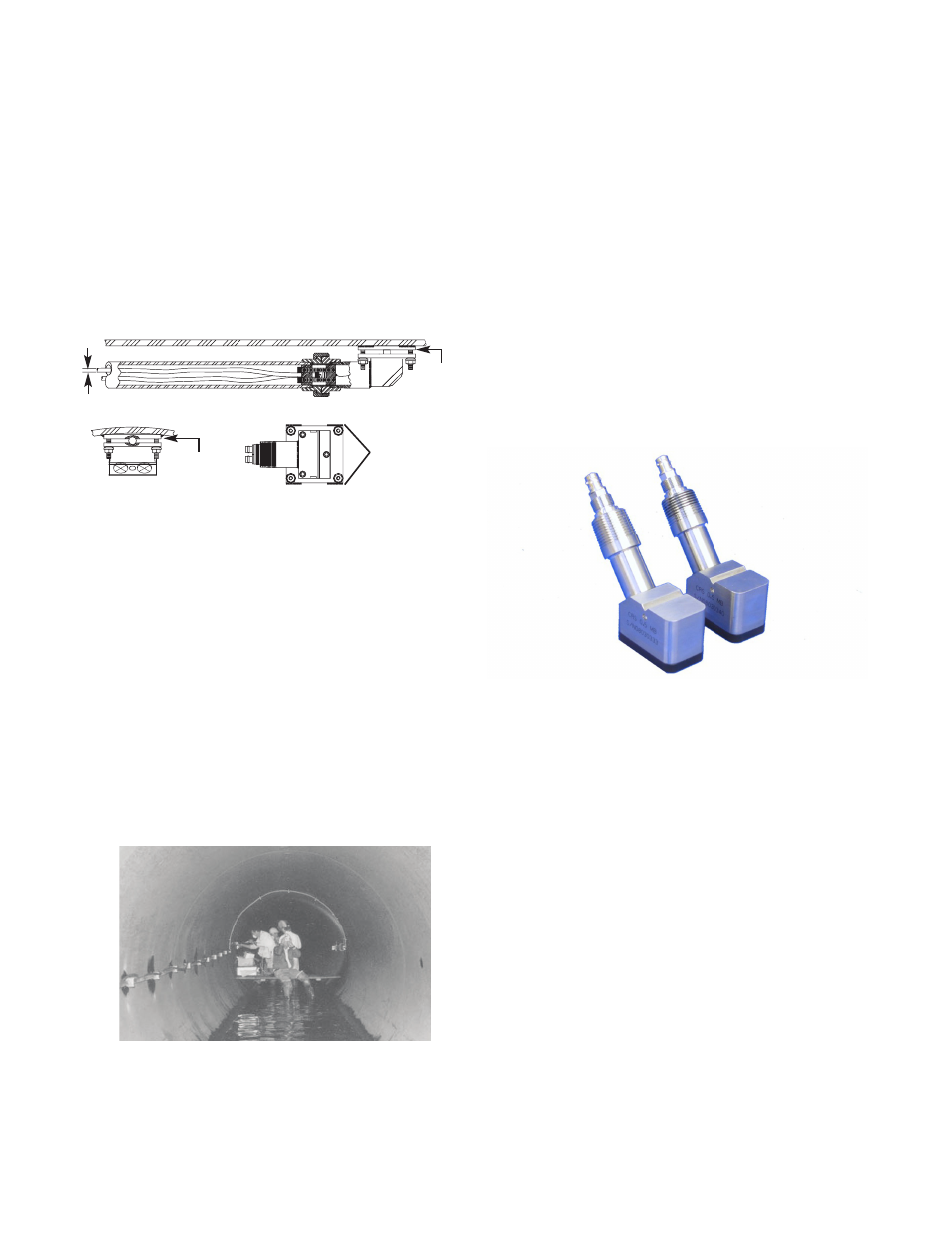

Clamp-In Capability

GE offers a wide variety of ways to install transducers to

adapt to each piping and application situation. For large

buried pipes, where access to the outside of the pipe

prevents using clamp-on or standard wetted

transducers, GE offers clamp-in transducers. These

transducers offer the unique ability to be attached to the

inner wall of large pipes. With a precision laser alignment

tool, the transducers, can be set up properly facing each

other, so when the water fills the pipe, the transducers

will work flawlessly. The clamp-on transducer is design

with a dual element head for 100% redundancy. GE is an

industry leader in transducer design with extremely low

failure rates. By making these transducers with two

elements, ensures years of operation without their ever

having to be serviced.

Clamp-On Avoids Plugged Impulse Lines

GE offers clamp-on transducers for a wide variety of

installations. One customer purchased the C-RS

transducer with a DigitalFlow DF868 to measure flow on

a 12 in (300 mm) crude resid stream. Previously, an

orifice plate was used for the measurement. The impulse

lines for the DP transmitter were consistantly getting

plugged, resulting in the need for service and unreliable

flow measurements. The clamp-on system offered by GE

was a preferred measurement setup because installation

could be done while the unit was operating, and no

additional restrictions that could cause pressure drop

were introduced. The customer saved approximately

US $50,000 in the first year, due to reduced maintenance

costs.

Pair of CRS transducers

Ø 0.25 in

(6.3 mm)

0.125 in

(3.175 mm)

0.125 in

(3.175 mm)

1/4-20 nuts for

adjusting the

transducers’

alignment during

installation