Ge sensing, Automatically adjusts to changing fluid properties, Is built to be economical and stay economical – Atec Panametrics-Olympus-DF868 User Manual

Page 3

GE

Sensing

Transmit

signal

Tracking

window

locked onto

receive signal

Time

Variable time

interval

Range of tracking window

Receive

signal

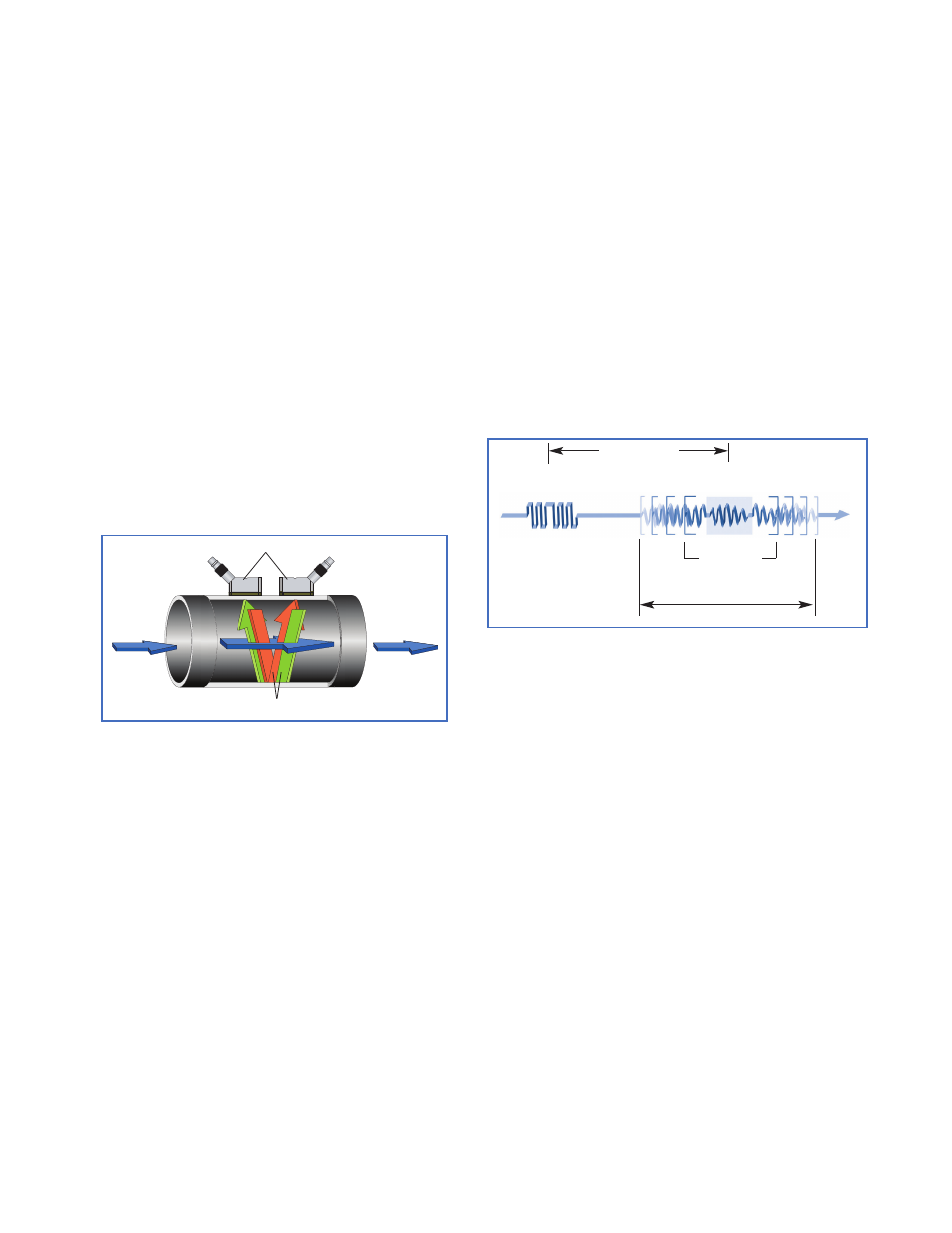

ATW ensures accuracy when fluid conditions change.

Flowmeter Transducers

Fluid

Flow

Ultrasonic Signal Path

Transit-time flow measurement technique

The difference between the downstream and upstream

transit times is proportional to the velocity of the flowing

liquid, and its sign indicates the direction of flow.

The DF868 Flowmeter

Uses the Transit-Time Flow

Measurement Technique

The transit-time technique uses a pair of transducers,

with each transducer sending and receiving coded

ultrasonic signals through the fluid. When the fluid is

flowing, signal transit time in the downstream direction is

shorter than in the upstream direction. The difference

between these transit times is proportional to the

velocity of the flow. The DigitalFlow DF868 measures this

time difference and uses programmed pipe parameters

to determine flow rate and direction.

Automatically Adjusts to Changing

Fluid Properties

Our unique Automatic Tracking Window™ (ATW™)

feature, standard in all DigitalFlow DF868 meters,

ensures accurate flow measurements even when fluid

properties are unknown or changing. Like the seek mode

on a car stereo, ATW dynamically sweeps the receiver

window whenever the sound speed of the fluid changes.

This powerful feature enables flow measurement when

the fluid sound speed is unknown, when it is changing

due to large temperature shifts, or when a new liquid

starts to flow in a multiproduct pipeline.

Is Built to Be Economical and

Stay Economical

To be of real value, a flowmeter must be as economical

to own and operate as it is capable in the field. Using the

latest microcircuit and manufacturing technologies, the

DigitalFlow DF868 flowmeter is built to stay in service for

many years. Completely solid state, the

DigitalFlow DF868 rarely wears out or needs servicing,

resulting in little downtime and low maintenance costs.

The DigitalFlow DF868 will continue to save money by

streamlining the measurement process and trimming

labor costs.

ATW works for both clamp-on and wetted transducer

applications by searching for a reliable ultrasonic receive

signal. It does this by varying the time between the

transmit signal and the receive signal window until the

receive signal is found. The tracking window

automatically sweeps through a range of time intervals

based on the minimum and maximum expected sound

speeds programmed by the user.

The window moves (tracks) in response to changes in the

fluid sound speed. Once the optimal signal is found, ATW

locks onto it until another large change in sound speed

occurs. When this happens, ATW returns to the seek

mode until the optimal signal is found again.