Atec Megger-bite-3 User Manual

Page 3

drop of the intercell connector to calculate the resistance

of the intercell connector. Then, it measures the strap

again without the instrument current. A mathematical

calculation is performed to determine float and ripple

currents and the intercell connection resistance.

The optional CT can be used with short strings in parallel

configurations to measure “escape current.” Other

techniques do not measure the current and can overstate

the health of batteries in these types of configurations. By

using a CT to measure the actual current in the cell being

tested, better results are obtained.

ProActiv can download string header info (with baselines

and limits) into the BITE 3 along with the most recent data

(even if measured by a different BITE). See Figure 3. Then

using the menus, simply scroll to the site and string and

start taking readings. When finished, close the test and

continue to the next string. At the conclusion of the test,

simply download to a PC for further data analysis and

long-term trending. Its versatility allows comments to be

added about the string. These comments will be uploaded

with the battery data. Additional comments about the site,

string and/or cell such as ambient and pilot cell

temperature can be stored by using the keypad to enter

them.

DATA ANALYSIS

The interface between BITE 3 and ProActiv is an

advanced, state-of-the-art feature that ensures that

everyone has access to the latest information and data on

which to base intelligent battery decisions. Not only can

emergency cell replacement criteria be developed but also

budgetary planning for string replacements can now

become part of the fiscal planning process.

ProActiv has the ability to download site and string

information and data as well as firmware updates to the

BITE 3. The data downloaded into the BITE 3 gives access

to the most recent data for the strings being tested during

the upcoming week or month.

BITE

®

3

Battery Impedance Test Equipment

FEATURES AND BENEFITS

■

Calculates impedance automatically

and stores results for on-site review to

make immediate decisions.

■

Serial connector for uploading stored

data to a personal computer and to

download data from ProActiv.

■

Measures lead-acid cells up to 2000 Ah

to test a wide range of batteries.

■

On-line testing requiring no downtime

and introduces less risk to battery

testing compared to load testing and

other techniques.

■

Stores more than 1 million cells’ data

in any string configuration – no need

to stop, download, delete and continue.

■

Firmware and software updates are fast and easy for

ProActiv and the BITE 3 through the Internet.

■

No programming skills required. ProActiv is an easy to

use, fully functional battery database capable of storing

as much information and data as your hard drive (or

network) has memory to store.

■

ProActiv has the ability to import images such as IR

thermographs, diagrams or photographs. This helps to

document visual inspections, string configurations,

installation techniques, or other aspects of battery

systems. Images and data are stored together, providing

convenient and easy access.

■

The BITE 3 and ProActiv accommodate multiple

languages.

TEST PROCEDURE

The BITE 3 works by placing the lead set at the cell

terminals to measure the voltage drop of the ac current

signal applied by the instrument to the cell while it is

on-line. During each measurement, impedance is

calculated following Ohm’s Law, displayed on the LCD,

and stored. It also measures, displays and records dc

voltage, interconnection (strap) resistance, float and ripple

currents. Float and ripple current measurements are

performed separately at the start of the test. This is

because current is the same everywhere in the series

connection of the string in accordance with Kirchhoff’s

law. All of these data together help determine the overall

health of the entire battery string’s electrical path from

terminal plate to terminal plate and to a lesser extent, the

charger (by measuring ripple current and its harmonic

content).

An innovative, patent-pending measuring technique is

being employed so that a clamp-on current sensor is no

longer necessary. It is well-recognized that the best way to

measure current is with a shunt. Since the battery has

many straps, simply by determining a strap’s resistance, it

can be used as a shunt to determine float and ripple

currents. First, while across an intercell connector, the

instrument applies a current and measures the voltage

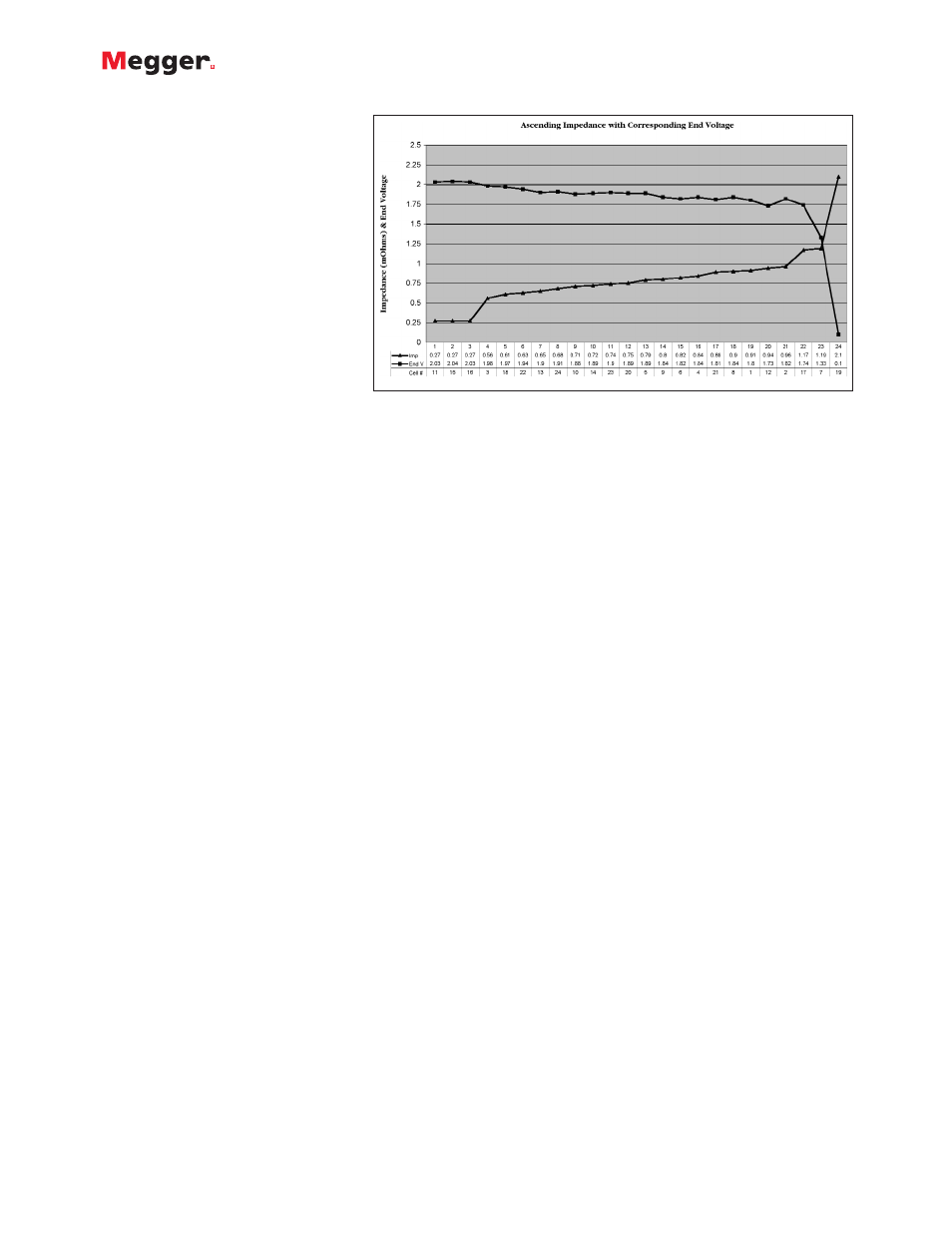

Figure 2: Ascending impedance compared to load test