Atec Megger-bite-3 User Manual

Page 2

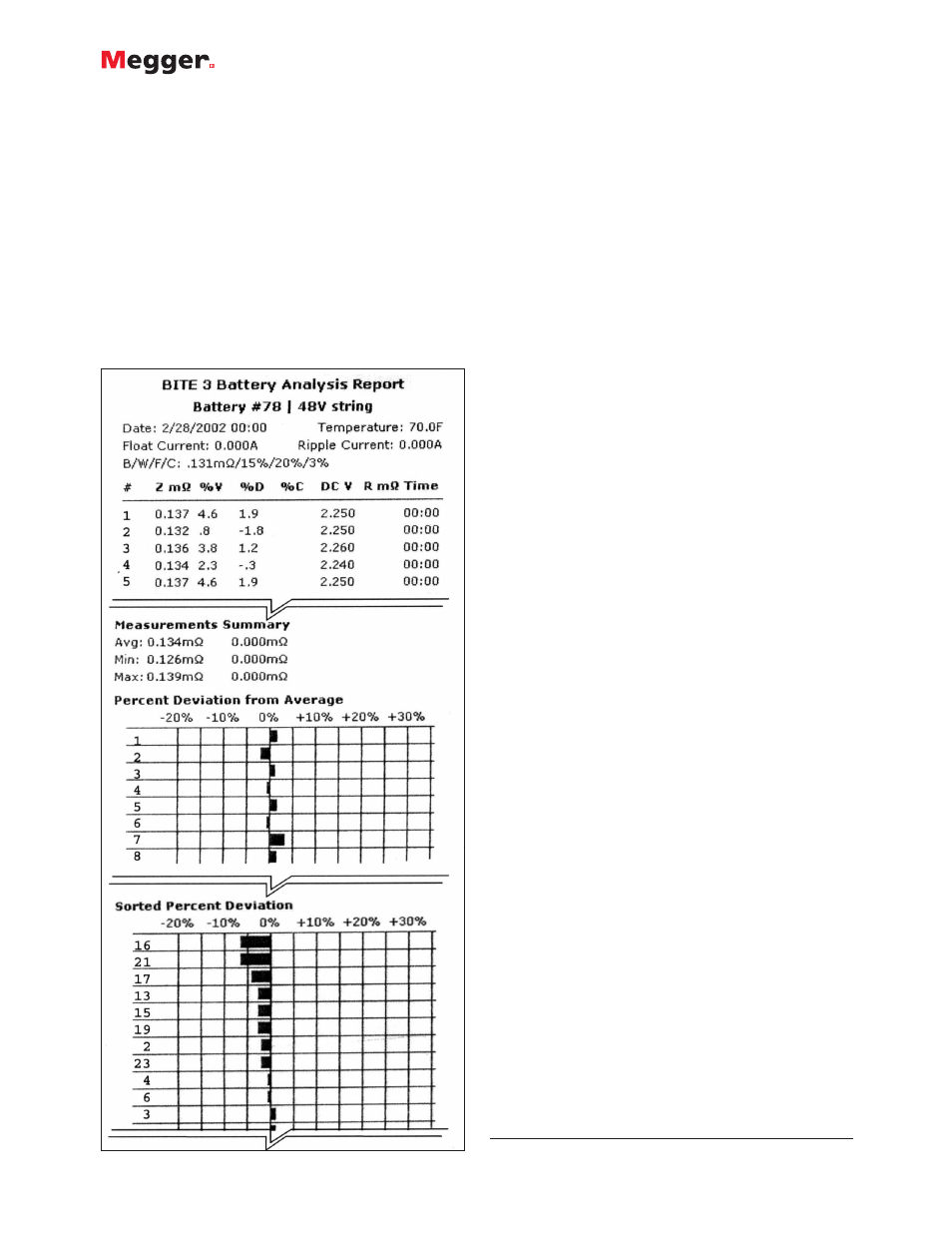

Figure 1: Battery Analysis Report

BITE

®

3

Battery Impedance Test Equipment

systems, operating controls, switchgear components,

protective relays and continuous process systems. Failure

of a battery system within environments such as utilities,

hospitals and manufacturing plants can result in

operational failure of the devices connected to it. ProActiv

assists the user to avoid battery failures, budget for future

battery string and cell replacements, and plan battery

changeouts in an orderly manner.

The BITE 3 along with ProActiv software offer the most

comprehensive data analysis system to provide confident

and reliable evaluation of batteries in the dc network.

Together, they combine to make the most powerful battery

health analyzer available on the market today.

APPLICATIONS

It is known that impedance is correlated to battery

capacity and there has been a long-standing question as to

when a user should replace a cell. See Figure 2. Recent

studies by EPRI* and other organizations indicate that

when the impedance of a sealed battery increases by

about 50% from its baseline value, the cell has degraded to

less than about 70% capacity. BITE 3 and ProActiv allow

the user to trend data and to enter baseline values for

comparison purposes and to make decisions whether on-

site or in the office. Both the BITE 3’s impedance

deviation graph and the trend graph in ProActiv clearly

show the status of a cell which helps users to decide what

action needs to be taken to ensure battery back up

reliability based on users’ criteria.

A battery’s internal impedance increases as its capacity

decreases due to various factors such as age, ambient

temperature, discharge history, etc. The BITE 3 measures

internal impedance and dc voltage for lead-acid cells up to

2000 Ah in capacity. It also measures intercell connection

resistance, float current and ripple current and the

harmonic content of the ripple current to provide a much

better evaluation than any other single instrument.

Impedance finds electrical path problems due to plate

sulphation, post-seal corrosion, dry-out (loss of

compression), poor intracell welds and intercell

connections and more. These data let the user determine

maintenance needs such as:

■

Cell replacement criteria based on impedance trends

■

Jumper out a cell or two

■

Clean and/or retighten intercell connectors

■

Shorten the maintenance interval, etc.,

■

Evaluate float current and ripple current effects

Typical installations that can be tested using the BITE 3

include:

■

Electrical power generation plants

■

Substations — utility, railroad, industrial

■

Telecommunications facilities — OSP, Wireless, POPs,

MTSOs, Fiber Regens

■

UPS systems — standard and cabinetized batteries

■

Railroad — Signals and Communications, CTC

■

Aircraft power supplies

■

Marine and military

*Stationary Battery Monitoring by Internal Ohmic Measurements

EPRI, Palo Alto, CA: 2002. 1002925