Building on field-proven technology, Csi 2140 machinery health analyzer, June 2013 – Atec Emerson-CSI-2140 User Manual

Page 4

CSI 2140 Machinery Health Analyzer

June 2013

Building on Field-Proven Technology

Emerson’s next generation vibration analyzer builds on the

field-proven, industry-leading technology of its predecessors.

The same great capabilities you count on in the CSI 2130 are

available in the CSI 2140.

Earliest Detection of Bearing and Gear Wear - Detecting

imbalance or misalignment is simple with most data collectors,

but these issues are the least impactful of the faults you will

find on your equipment. Over 50% of mechanical faults are

due to bearing and gearbox issues. And most data collectors

do not have the technology to detect these faults as they are

developing – and can only find them when the machinery is

already damaged and near failure.

The CSI 2140 uses Emerson’s patented PeakVue

™

processing

and applies digital technology to determine bearing and gear

wear earlier than any other technology. By measuring stress

waves emitted from impacting – the earliest sign of bearing

and gear wear – the CSI 2140 gives you time to plan for

maintenance on your machine – while avoiding significant,

and costly, damage.

PeakVue technology not only offers the earliest warning of

developing faults, it also provides an indication of severity.

Measurements can be translated into reliable trends to

determine the optimal timing for maintenance. Machinery

faults are clearly visible in the waveform, opening up new

options for fault detection and diagnosis.

www.assetweb.com

4

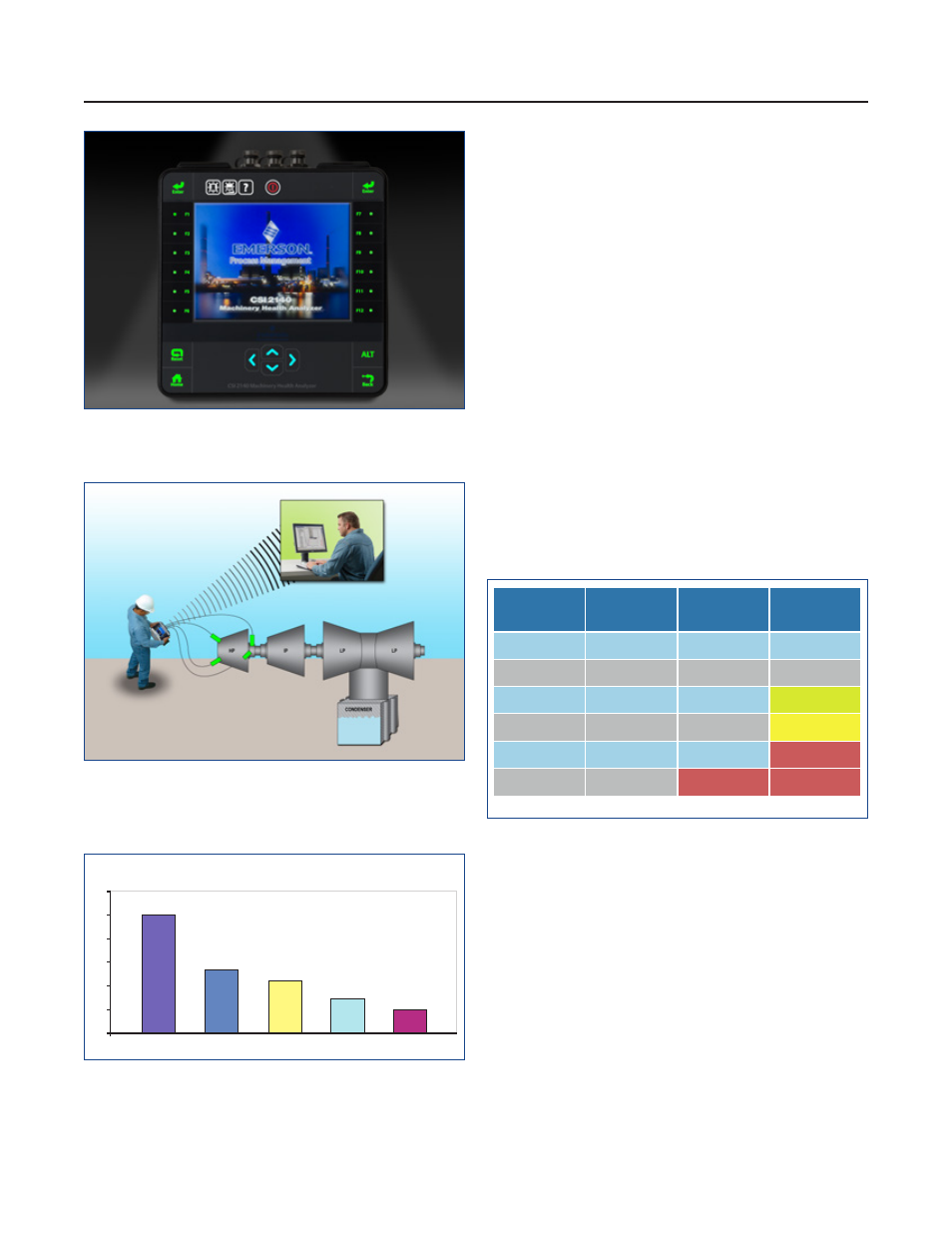

Failure

Typical values for a Horizontal Pump, direct coupled, with machine speed of 600-60000 RPM.

0%

>0.30

>40

4

<1%

0.45

25

3

<5%

0.25

12

2

<10%

0.20

8

1

<20%

0.15

4

0

20-100%

0.15

0

Bearing Life

Remaining

State

Vibration

(in/sec)

PeakVue

(g’s)

300

Tempo de Correção de Dados Relativos em Segundos

CSI 2120

Analyzer

213

CSI 2130

1 Ch.

Analyzer

133

CSI 2130

2 Ch.

Analyzer

108

CSI 2130

2 Ch.

Analyzer

with Triax

73

CSI 2140

4 Ch.

Analyzer

with Triax

55

250

200

150

100

50

0

Wireless transmission of route data from the field to the analyst

back at the office allows collection and analysis to be performed in

parallel

PeakVue data provides the earlier indication of developing faults in

bearings and gearboxes

The backlit keypad and ambient lighting of the larger, brighter

screens makes the CSI 2140 visible in any environment.