Motor circuit analysis, Introduction to motor circuit analysis – Atec All-Test-IV-Pro User Manual

Page 4

Introduction to Motor Circuit

Analysis

One of your motors has just stopped running, and your

production has stopped. Is the problem mechanical or

electrical? Is it the drive? Overload? Load? Connections?

Capacitors? Finding the root cause could take hours.

And could you have seen it coming? Could you have identified

the potential fault in advance, and corrected the issue through

scheduled maintenance, and avoided the unplanned

shut-down?

From the day you install a motor, it is in the process of failing.

The only question is when. According to an EPRI study,

almost half of all motor failures are electrical in nature (the

rest are mechanical). The majority of electrical motor faults

start as shorted turns within the windings.

In addition, poor connections, winding contamination,

and rotor issues all lead to motor failure.

Some facts about winding faults:

• They usually start in the end-turns of the windings where stress is greatest, and the insulation system

is the weakest

• They start small, and escalate over time

• They sometimes progress to a ground fault

• They always end in motor failure

• You can’t detect them with a Megohm meter or DMM until the motor has totally failed

Motor Circuit Analysis (MCA)

MCA is a technology that lets you examine the electrical health of a motor through measuring multiple

electrical properties of the windings. The ALL-TEST IV PRO

™

Motor Circuit Analyzer performs 5

measurements on each of the three winding phases:

• Winding resistance, impedance, and inductance is measured

• A low voltage AC signal is applied, and the resulting phase angle is measured

• A multiple frequency current response test (I/F) is performed

• Insulation resistance to ground is measured at either 500 or 1000 V

In a healthy motor, all of these measurements are balanced. When one or more is out of balance, you have

a clear indication of where the fault most likely is. For example if all measurements except resistance are

balanced, a loose connection is indicated. Unbalance in the phase angle or I/F test indicates shorted turns

within the windings. You can also isolate and identify rotor faults, and eccentricity in assembled motors

without run testing under load!

Extensive research and field tests have shown that the guidelines for detecting fault conditions are the

same on any size and type of device—we have successfully evaluated 40,000 HP synchronous machines,

tool machine servos, induction motors of all sizes and voltages, and even pad and pole mounted distribution

transformers. And you can rely on the results—there are virtually no “false” positives or negatives.

Most tests are done from the motor control center, through cable runs of 1000 feet or more. All tests are

low voltage and totally non destructive, so there is no danger of damaging sensitive equipment. A test

takes less than 3 minutes, and can show you turn, coil, and phase-to-phase faults, open phases, poor

connections, contaminated or burned windings, grounded windings and connections—or a motor that is

perfectly healthy.

There is no more powerful instrument for electrical

motor evaluation!

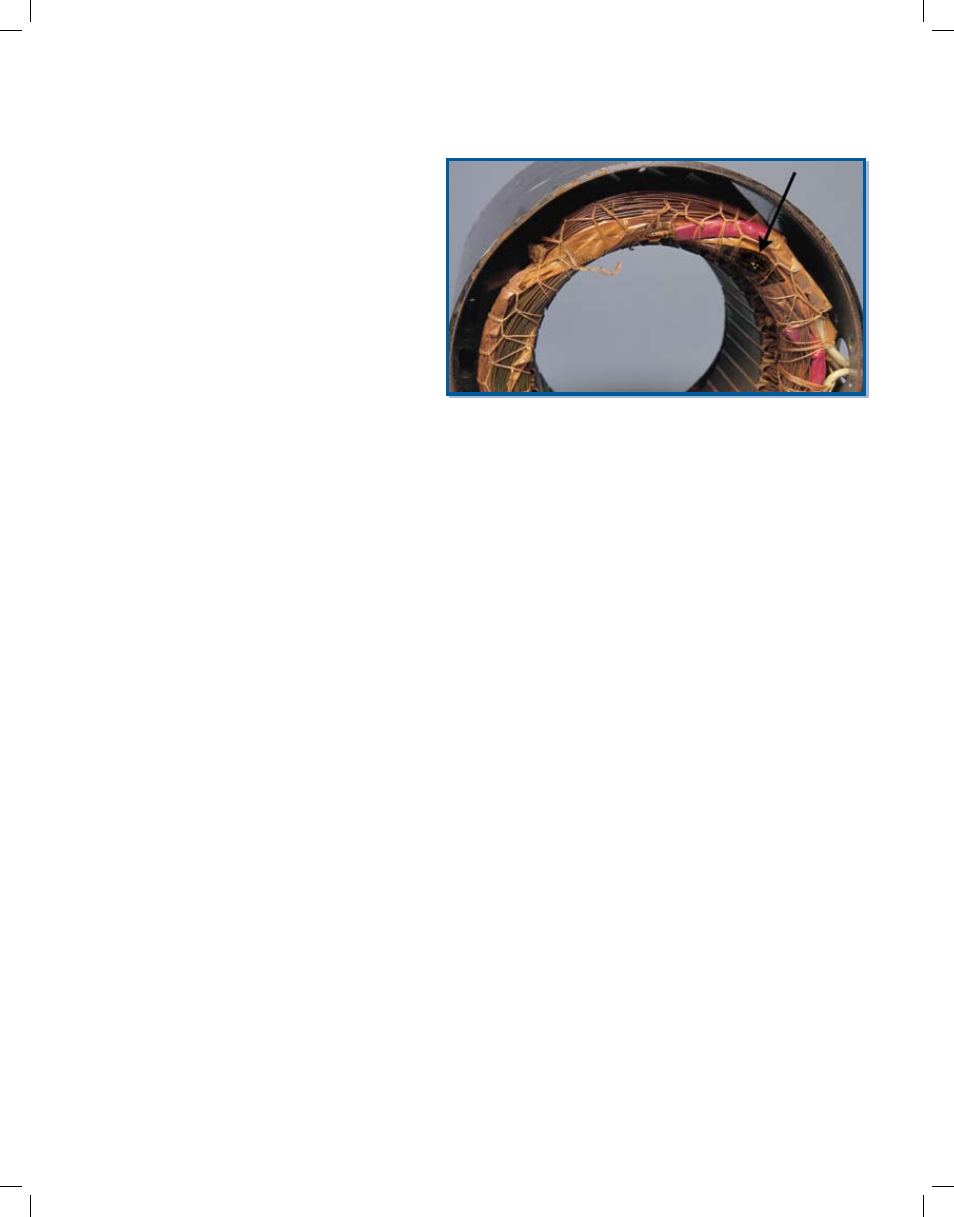

Once your motor looks like this, it’s too late!

MOTOR CIRCUIT ANALYSIS