Danger, Warning – Elmo Rietschle L-BL2 User Manual

Page 24

Shutting Down and Longer Standstill

610.44444.40.000

24 / 36

© Gardner Denver Deutschland GmbH

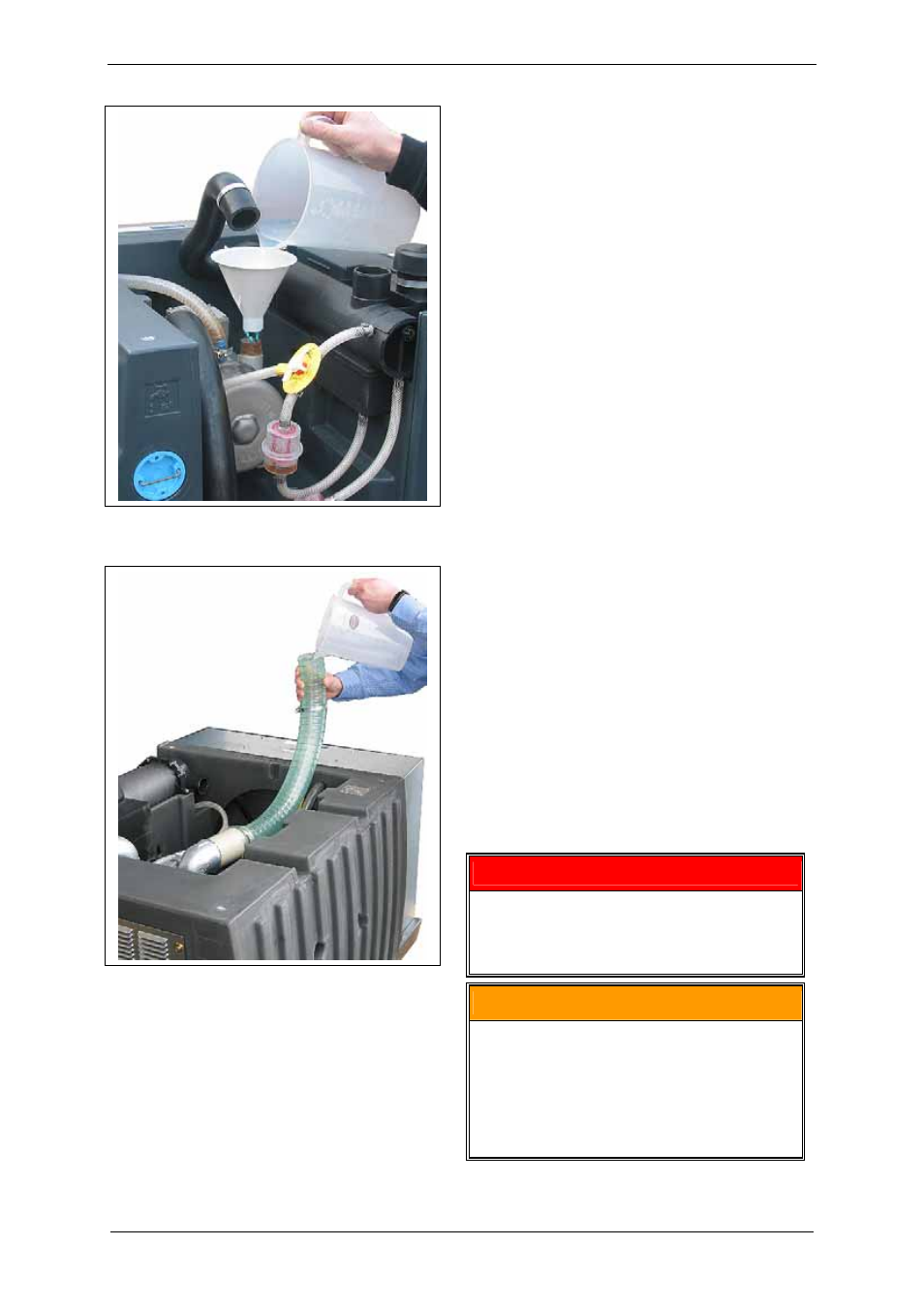

Fig. 13: Pouring preservative/antiliming liquid

into installed unit

(for models 2BL2 041 - 2BL2 141)

Fig. 14: Pouring preservative/antiliming liquid

into installed unit

(for models 2BL2 251 - 2BL2 341)

8.3 Storage

conditions

This chapter applies in the following cases:

New

systems,

Systems that are already installed in a system

and were prepared for a longer standstill, as

described in Chapter 8.2, "Preparing for

longer shut-down", Pg. 23.

To prevent standstill damage during storage, the

environment must provide the following

conditions:

dry,

dust-free,

low-vibration (effective value of vibration

speed v

eff

≤ 0.2 mm/s [0.008"/sec]).

Take the following measures for commissioning

following a longer standstill

:

Measure the insulation resistance of the

motor.

In case of values ≤ 1kΩ per volt of nominal

voltage, dry winding.

Drain off the anti-corrosive agent via the drain

opening of the installed unit, as described in

Chapter 8.1, "Draining", Pg. 23.

Dispose of preservative in accordance with

the manufacturer's specifications.

Then clean the system:

Pour operating liquid into the system via the

filling opening (Fig. 1, Pg. 3, Item 007).

If appropriate, Briefly operate the system to

circulate the operating liquid in the system.

See Chapter 6.1, "Preparation and start-up",

Pg. 20.

Switch off the system again. See Chapter 6.2,

"Shut-down", Pg. 20.

Drain the system. See Chapter 8.1,

"Draining", Pg. 23.

For new systems:

Install the system as described in Chapter 5,

"Installation", Pg. 12.

Commission the system as described in

Chapter 6, "Commissioning", Pg. 20.

For systems that are already installed in a

line:

Commission the system as described in

Chapter 6, "Commissioning", Pg. 20.

DANGER

Electrical danger!

Work on electrical installations may be carried

out by trained and authorised electricians only!

WARNING

Danger of slipping due to escaping

operating liquid!

When draining the system, operating liquid will

be discharged downward via the opening in the

bottom of the separator. Have a catch

container ready under the system.