Caution, Warning – Elmo Rietschle L-BL2 User Manual

Page 18

Installation

610.44444.40.000

18 / 36

© Gardner Denver Deutschland GmbH

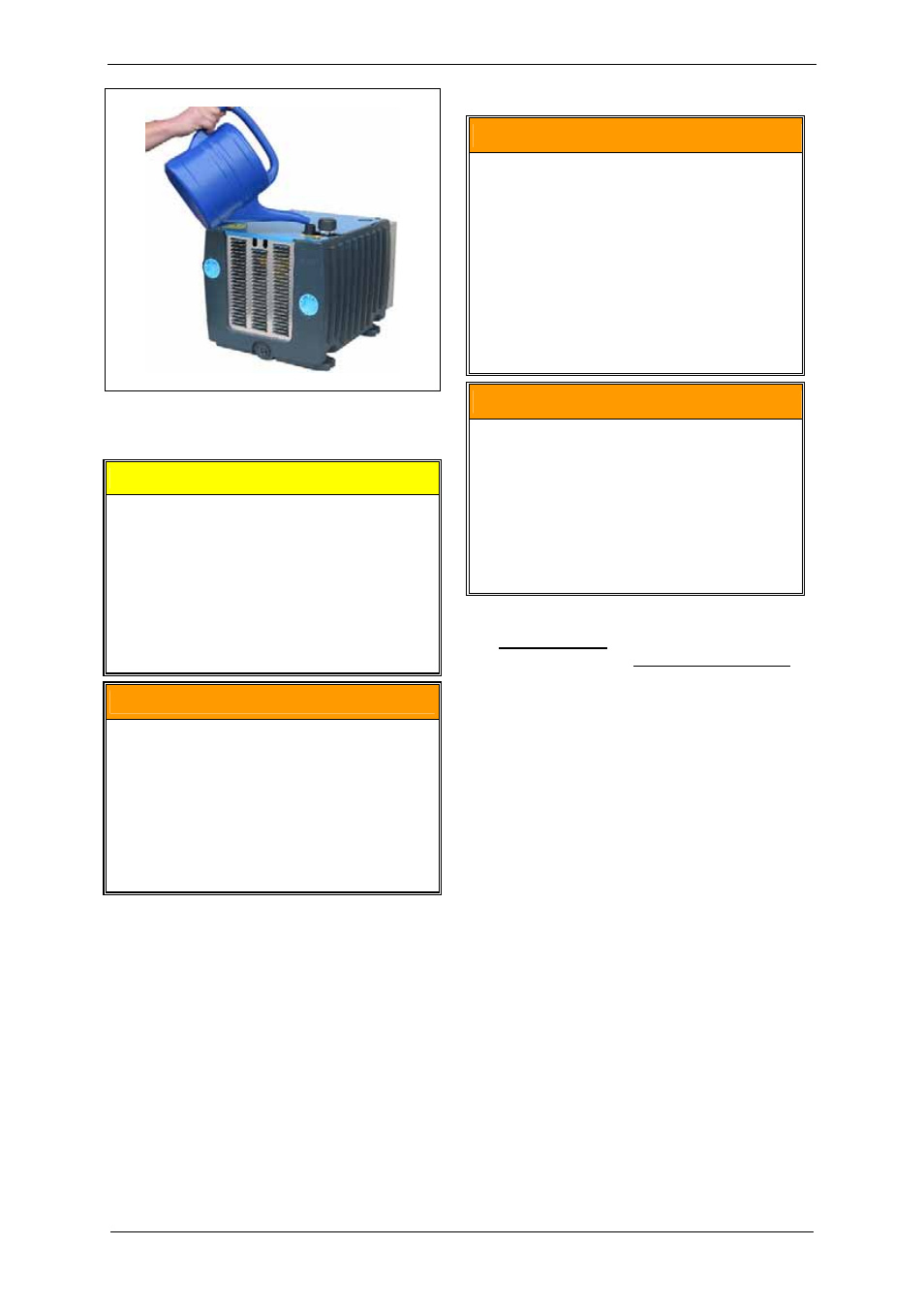

Fig. 9: Filling installed unit (via inlet

connection)

CAUTION

If the installed unit is run dry, the mechanical

seal will be destroyed in a matter of seconds!

DO NOT switch on until the following

conditions are met:

The separator must be correctly filled with

operating liquid.

The interior of the installed unit must be

filled with operating liquid.

WARNING

Danger due to escaping fluid!

Make sure that all openings in the separator

(feed/drain regulator connection, fill opening,

drain opening) are tightly closed (by means of

screwed-in bung plugs or installed feed

regulator, drain regulator and drain valve)

when the separator is filled with operating

liquid.

5.4 Connection

of

pipes/hoses

WARNING

Danger from vacuum!

Do not operate the unit unless the pipe / hose

has been fitted to the inlet connection!

If there is a danger that the system could suck

in:

Do not go near the inlet connection with

long, open hair or loose fitting clothing,

Do not look into the inlet connection or

move your eyes in front of the inlet

connection opening.

WARNING

Danger from vacuum!

Danger due to escaping fluid!

During operation connected pipes and vessels

are vacuumised!

Make sure that all connections are sufficiently

tight! Use only pipes and vessels of sufficient

strength!

The pumped gases/vapours are sucked in via

the inlet connection (see Chapter 5.4.1, Pg. 18)

and discharged via the exhaust-air connection

(see Chapter 5.4.2, Pg. 19).

5.4.1 Inlet

connection

Remove sealing plug

To prevent the penetration of foreign bodies, the

connection opening on the inlet connection

(Item A) is sealed off on delivery.

Do not remove the sealing plug until immediately

before connecting the pipes/hoses.

Check valve:

In the following cases a check valve must be

attached to the inlet connection (Item A):

If two or more systems are operated in

parallel, e.g. reserve system.

(Note: A separate check valve must be

attached to the inlet connection on each

system.)

If a vacuum can occur for more than

one minute in the connected intake line on the

system switched off.

The check valve prevents the backflow of

pumped gases/vapours from the system during

an interruption in operation.