Elmo Rietschle S-VSI 300(42) User Manual

Page 30

30

|

www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

Maintenance and repair

m

q

n

s

5

k

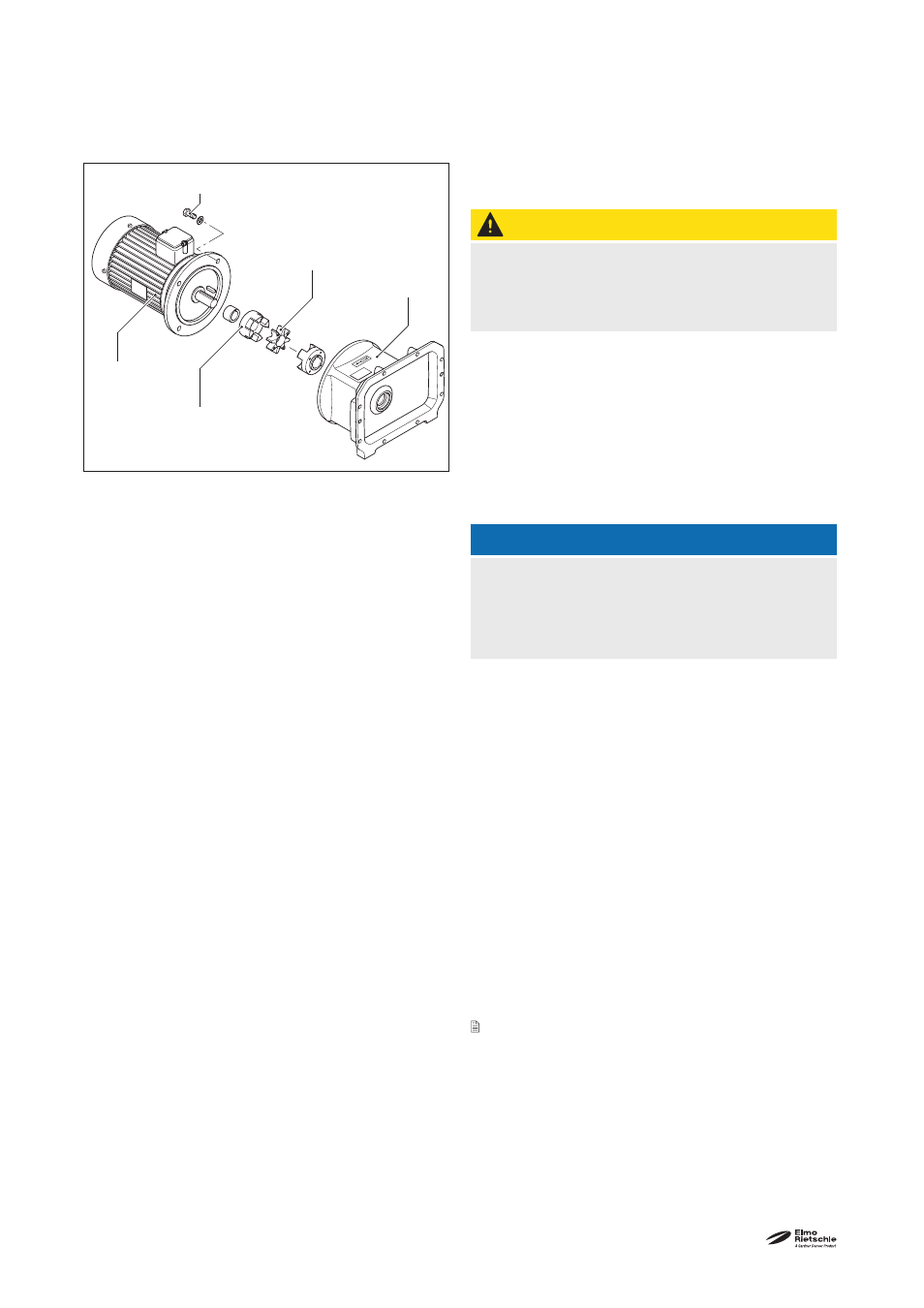

7.2.3 Coupling

The coupling sprocket (Fig. 13/k) is subject to wear

and must be checked regularly (at least once a year).

CAUTION

Defective coupling sprocket

Defective sprockets may lead to the rotor shaft

breaking.

To check the coupling switch the motor off and

ensure that it cannot be switched on again.

Suspend the motor (Fig. 13/m) on the eyebolt by

means of lifting equipment.

Undo the screws (Fig. 13/s

5

) on the motor fl ange.

Remove motor and the coupling half on the mo-

tor side (Fig. 13/q) from the motor fl ange housing

(Fig. 13/n) axially. If the sprocket (Fig. 13/k) is dam-

aged or worn, then replace it.

NOTICE

Frequent starting up and high ambient tem-

perature

The service life of the sprocket (Fig. 13/k) is reduced

as a result of this.

Re-assemble in reverse order.

Fig. 13 Coupling

k

Coupling sprocket

m

Motor

n

Motor fl ange housing

q

Coupling half on the motor side

s

5

Screws

7.2.4 Cooling

Check the cooling water system and the pipes

monthly.

Continuous fl ow cooling

The dirt trap (Fig. 5/U

6

) must be cleaned periodically,

depending on the cooling liquid quality. To do this

unscrew the lock screw and clean the built-in mesh

fi lter.

Circulation cooling

For maintainance see Operating Instructions, is

enclosed on the cooling device