Elmo Rietschle S-VSI 300(42) User Manual

Page 29

29

www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

|

Maintenance and repair

f

4

f

4

h

1

f

3

g

1

1

2

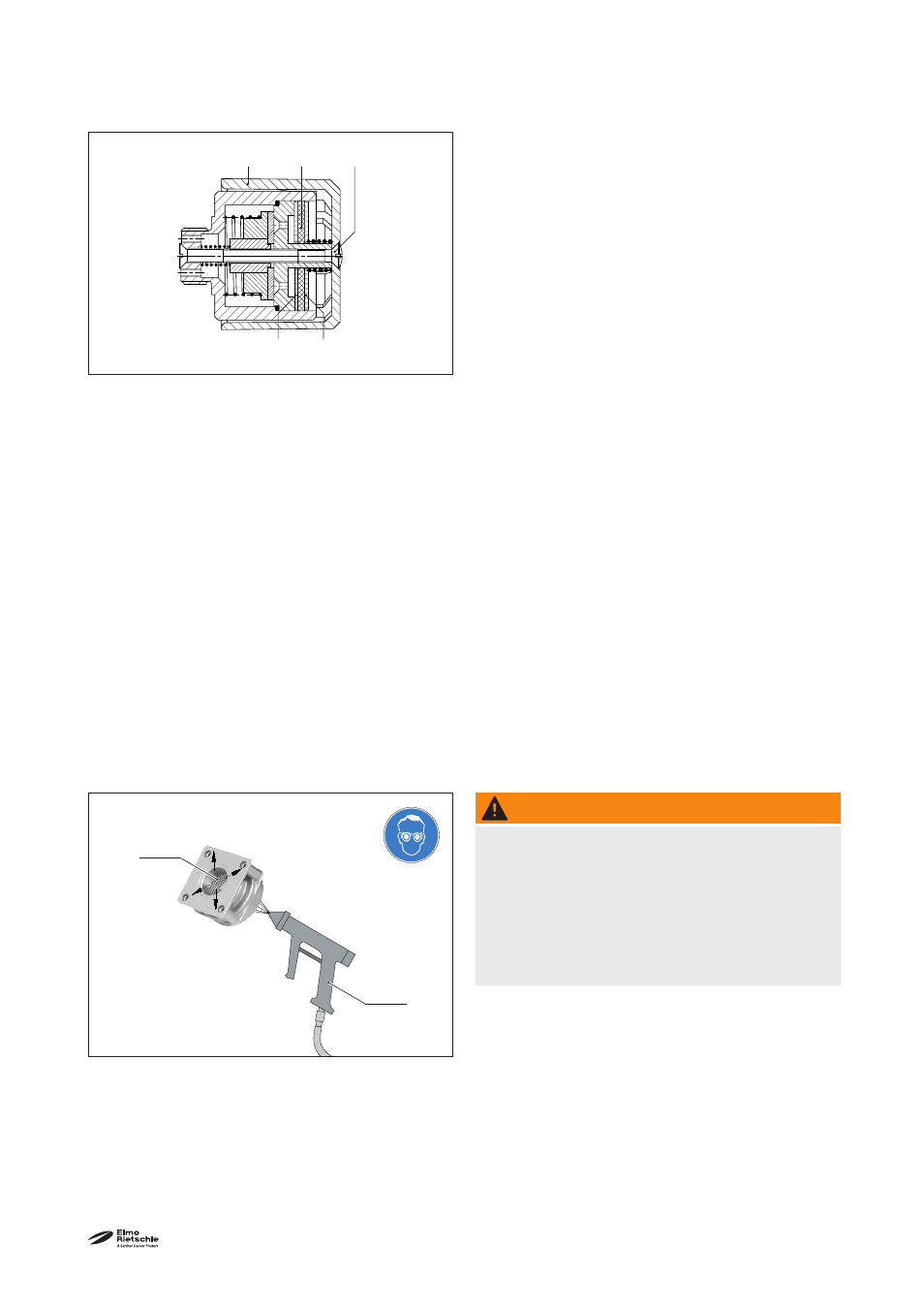

Fig. 12 Blowing out the mesh fi lter

1 Mesh

fi lter

2

Compressed air

Gas ballast valve fi lter:

The pumps work with a gas ballast valve (Fig. 10/U).

The inbuilt fi lter disc Fig. 11/f

3

) and micro fi lter discs

Fig. 11/f

4

) must be cleaned more or less often by

purging depending on how dirty the medium fl ow-

ing through is. By undoing the countersunk screw

(Fig. 11/g

1

) and removing the plastic cover (Fig. 11/

h

1

) the fi lter parts can be removed for cleaning.

Re-assemble in reverse order.

Fig. 11 Gas ballast valve

h

1

Cover

f

3

Filter

disc

g

1

Countersunk

screw

f

4

Micro

fi lter discs

WARNING

Danger of injury when dealing with com-

pressed air

When blowing through with compressed air, solid

particles may be carried along or powder dust swirl-

ing around may cause injury to the eyes.

Therefore, when cleaning with compressed air always

wear goggles and a dust mask.

- S-VSA (68 pages)

- S-VSB (12 pages)

- S-VSI 100(01)/300(01)/300(12) (38 pages)

- S-VSI 300(44) (36 pages)

- C-VLR 60/100/120/150/251 (34 pages)

- C-VLR 301 (30 pages)

- C-VLR 1000 (28 pages)

- C-DLR 60/100/120/150/250/300/400/500 (34 pages)

- C-KLR 80/140 (30 pages)

- R-WVB (23 pages)

- R-VWP 500/1000/1500/2500 (38 pages)

- V-VTE 3/6/8/10 (28 pages)

- V-DTE 3/6/8/10 (28 pages)

- V-VTN 6/10/15/25/40/60 (30 pages)

- V-VTN 16/26/41 (30 pages)

- V-DTN 6/10/15/25/40 (30 pages)

- V-DTN 16/26/41 (30 pages)

- V-KTN 15/25/40 (30 pages)

- V-KTN 16/26/41 (30 pages)

- V-VTA 60/80/100/140 (32 pages)

- V-DTA 60/80/100/140 (32 pages)

- V-KTA 60/1-140/1 (32 pages)

- V-KTA 60/4 (32 pages)

- V-VTR 100/140 (32 pages)

- V-DTR 100/140 (32 pages)

- V-KTR 100/140 (32 pages)

- V-VGA 4/6 (30 pages)

- V-VGD 10/15 (32 pages)

- V-VCB 20/25 (32 pages)

- V-VCA 25/40 (34 pages)

- V-VC 50/75/100/150 (32 pages)

- V-VC 202/303 (32 pages)

- V-VC 400/500/700/900/1100/1300 (34 pages)

- V-VL 10/25/40/80/100 (32 pages)

- L-BV3 (32 pages)

- L-BV2 Operating instructions (32 pages)

- L-BV2 Supplementary instructions (12 pages)

- L-BV7 (64 pages)

- L-BL2 (36 pages)

- F-CEV-S (26 pages)

- F-CEVF (29),(30),(39) (26 pages)

- F-CEVF (31),(41),(43) (26 pages)

- F-RER (28 pages)

- G-BH10 (30 pages)