Elmo Rietschle S-VSI 300(42) User Manual

Page 26

26

|

www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

Maintenance and repair

7

Maintenance and repair

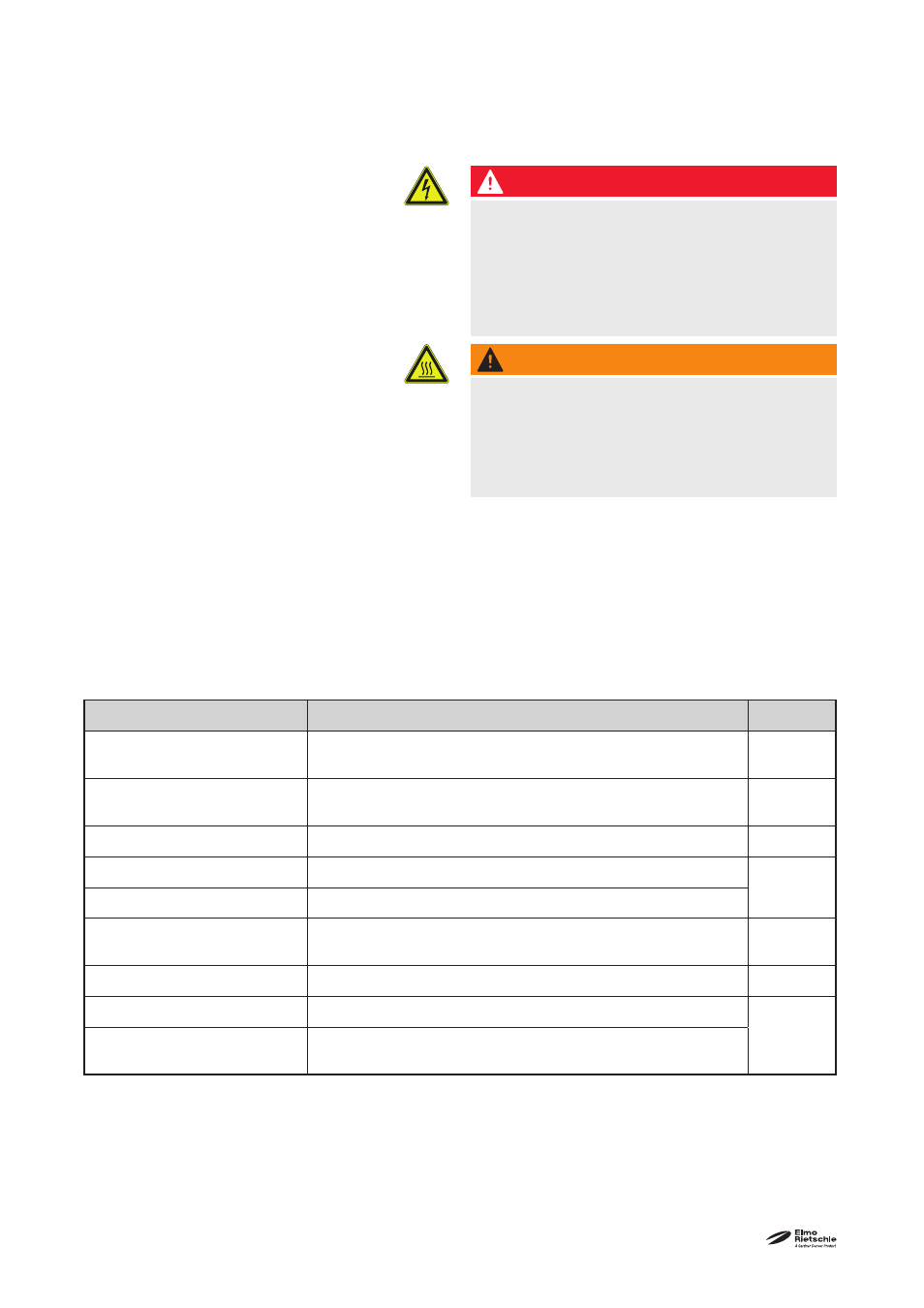

DANGER

Danger of death from touching live parts!

Before maintenance work disconnect the machine

by pressing the main switch or unplugging it and

ensure that it cannot be turned on again.

WARNING

Hot surfaces and equipment

During maintenance work there is the danger of

getting burnt on hot components (Fig. 2/Q) and

by the machine lubricating oil.

Wait for the machine to cool down.

7.1 Ensuring

operational

safety

Regular maintenance work must be carried out in order to ensure operational safety.

Maintenance intervals also depend on the operational demands on the machine.

With any work observe the safety instructions described in Section 2.8 “Safety notes for installation, com-

missioning and maintenance”.

The whole unit should always be kept in a clean condition.

7.2 Maintenance

work

Interval

Maintenance to be carried out

Section

monthly

Check the pipes and screws for leaks and to ensure they are

seated properly and if necessary seal again or tighten up.

—

monthly

Check the terminal box and cable inlet holes for leaks and if

necessary re-seal.

—

monthly

Clean cooling ribs of the machine and the motor.

—

monthly

Check the oil level

7.2.1

7.500 h

Changing the oil

depending on how dirty the

discharged medium is

Clean intake air fi lter

Clean gas ballast valve fi lter

7.2.2

at least once a year

Check for coupling wear

7.2.3

monthly

Check the cooling water system and the pipes.

7.2.4

depending on how dirty the

cooling liquid is

Clean dirt trap