Roll seal, 700 series, Principle of operation – Cla-Val 790-01 User Manual

Page 4: Model

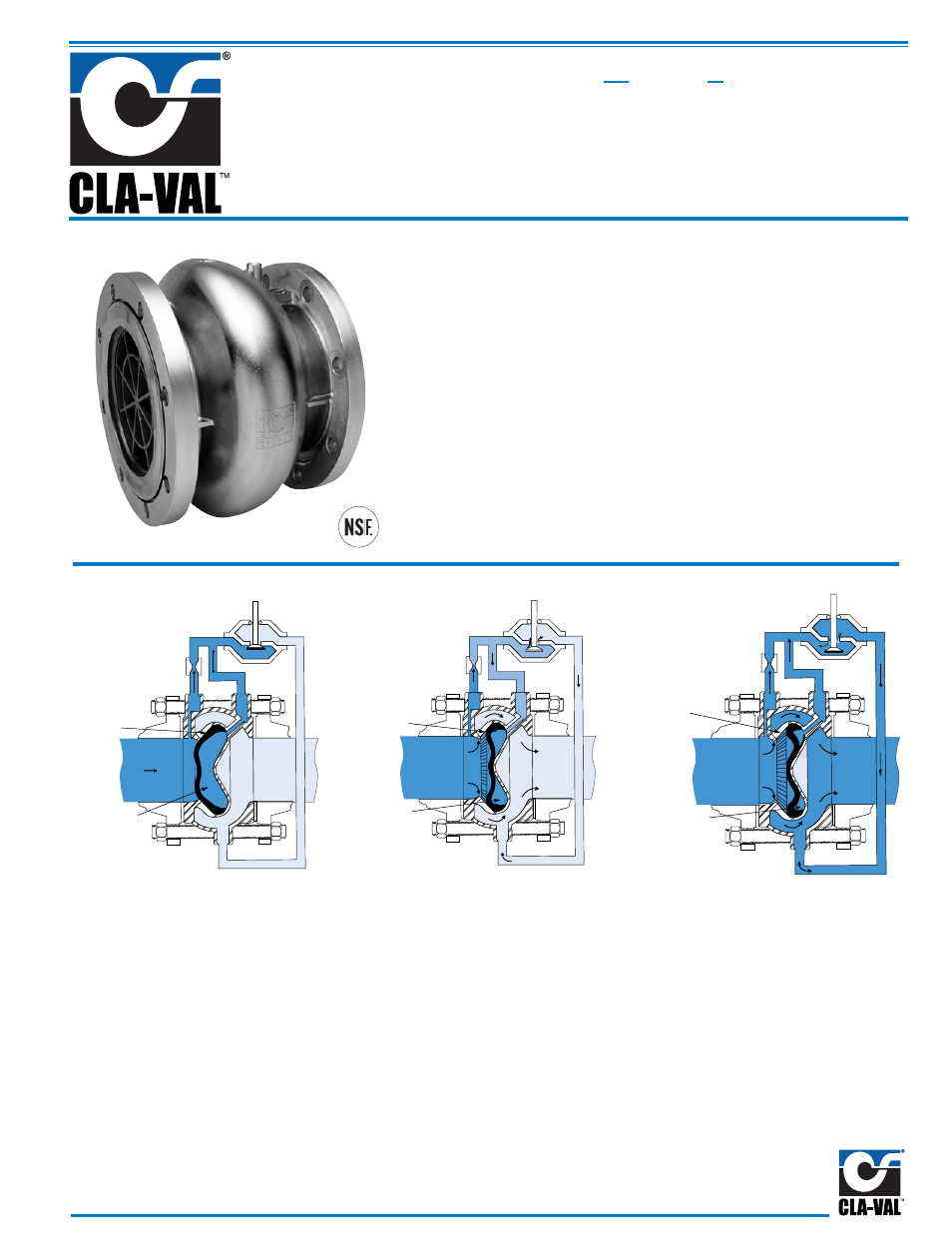

Principle of Operation

Model 100-42 Valve

in Closed Position

Upstream pressure is introduced to the

control chamber (the chamber formed

behind the liner) of the Cla-Val Model

100-42 Roll Seal valve through the con-

trol piping and restrictor. When the pilot

is closed, full inlet pressure is supplied

to the control chamber, thus balancing

the force developed by inlet pressure

acting on the upstream face on the

liner. Under these conditions, the liner

remains in the fully closed position.

Since the operating pressure in the

control chamber is greater than the out-

let pressure, an additional closing force

is developed across the liner, pressing

the liner against the surrounding slotted

grillwork area and seating surface.

Model 100-42 Valve

in Partially Open Position

As loading pressure is lowered slightly

below inlet pressure, the central portion

of the liner is forced to invert and come

to rest against the tip of the control

chamber cavity. Reducing the loading

pressure further (but still higher than

outlet pressure) causes the liner to

drape over the cone shaped portion of

the control chamber cavity. This action

causes the outer section of the liner to

roll off the seating surface and a portion

of the grillwork to partially open the

valve.

Model 100-42 Valve

in Fully Open Position

The valve is fully opened when loading

pressure is sufficiently reduced to allow

the liner to roll back completely and

expose the full slot area. Restoring

loading pressure reverses the liner

rolling action to return the liner to the

fully closed position.

PILOT

CONTROL

VALVE

RESTRICTOR

SEATING AREA

CONTROL CHAMBER

INLET

Pilot

Control

Valve

RESTRICTOR

SEATING AREA

CONTROL CHAMBER

INLET

PILOT

CONTROL

VALVE

RESTRICTOR

SEATING AREA

INLET

CONTROL CHAMBER

100-42

ROLL SEAL

700 SERIES

MODEL

• Compact Design, Proven Reliable

• Light Weight Materials

• High Pressure Rating Availability

• Easy Installation and Maintenance

The Cla-Val Model 100-42 Roll Seal valve is a hydraulically operated valve used

to control liquid flow by means of a flexible control element: the liner.

The basic valve consists of only two parts: a one piece, investment cast body

and an elastomeric liner. The valve body is constructed with internal ribs and

slots forming a grillwork which surrounds the liner to provide support. A normally

closed type valve is formed by the installed liner which covers the grillwork and

seats against the raised seating surface in the valve body.

Upstream pressure actuates the valve to produce valve opening by rolling the

liner off the seating surface and the slotted grillwork.

The valve is actuated by upstream pressure as the loading pressure (pressure

supplied to the control chamber) is varied by an external pilot control system.

A typical pilot control system used to operate the Model 100-42 valve consists

of a restriction and a suitable pilot connected to the valve.