Cla-val, 501a wafer swing check valve – Cla-Val 501A Series User Manual

Page 4

CLA-VAL

Copyright Cla-Val 2011 Printed in USA Specifications subject to change without notice.

P.O. Box 1325

• Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: [email protected] • Website cla-val.com

©

E-501A (R-3/2010)

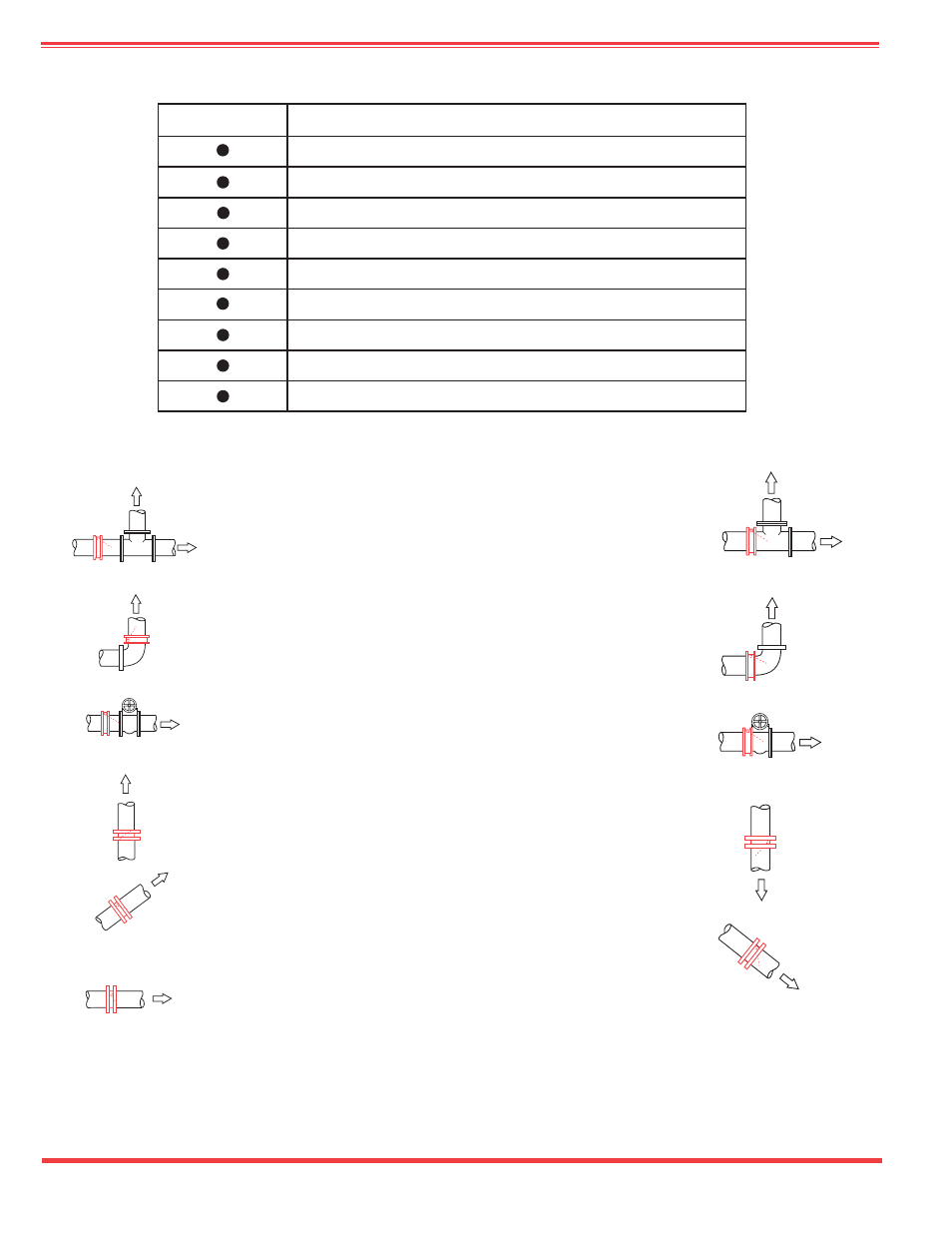

501A Wafer Swing Check Valve

NORMAL FLOW

NORMAL FLOW

NORMAL FLOW

Note Hinge

Position

NORMAL FLOW

Note Hinge

Position

NORMAL FLOW

NORMAL FLOW

NORMAL FLOW

NORMAL

FLOW

Note Hinge

Position

Typical Applications with

Correct Valve Location

Avoid These Applications

with Incorrect Valve

Location

Feature

1.

Lowest initial cost

2.

Shortest lay length

3.

Lowest head loss (see head loss curves

4.

Resilient seat (standard)

5.

For waste and raw sewage

6.

For Clean water

7.

Buried service

8.

Vertical installation flow up only

9.

Flow Velocities up to 25 FPS

Recommendations for Installation Position

1. Install the valve in horizontal or upward flow for proper valve closure.

Caution: Do not use with reciprocating compressors, or in other pulsating

services.

Note:

Allow minimum (2) pipe diameters clearance downstream of check

valve with disc open to promote smooth flow.

INSTALLATION

Wafer style check valves are designed to fit between ANSI Class 125 and

Class 150 flat faced flanges. Two standard flange gaskets are recommend-

ed when installing 2” - 12” 501A valves. 14” and larger 501A valves do not

require gaskets. Determine minimum bolt or stud length by adding check

valve length to ANSI bolt or stud length.

Check Valve Length is Dimension B for 2” - 12” and Dimension D for 14” -

30” valves. ANSI bolt or stud length can be found in the following stan-

dards: For Class 125 use AWWA/ANSI standard B16.1. For Class 150 use

AWWA/ANSI standard B 16.5.