Cf1 series, Cf1 series float controls – Cla-Val 124-02/624-02 Technical Manual User Manual

Page 19

CF1 Series Float Controls

CF1 Series

INSTALLATION / OPERATION / MAINTENANCE

Initial Adjustment CF1 Series Float Controls

Check installation to be sure that liquid surface is not subject to wind or currents, if so, a stilling well should be

installed around the float and rod assembly. A short section of 8" pipe (PVC) mounted vertically in the tank

around the float and rod is suggested.

1. See parts sheet (other side of this sheet) for proper assembly of the float rod, float, and stop collars and for

threading into the Link Assembly of the CF1-C1.

2. Balance the Float Rod Assembly. This compensates for the buoyancy of the float rod in the water.

Temporarily remove float by removing float rod and float from the link assembly. Remove float from float rod,

reinstall rod assembly (leave stop collars on float rod) back into link assembly.

Adjust counterweight on rod to balance the weight of the float rod assembly less the float. Loosen setscrew on

counterweight and move weight in or out round rod remains horizontal without shifting. Tighten setscrew.

Check by pushing up or down on float rod assembly and seeing that entire assembly returns to balanced posi-

tion. Replace float between the stop collars. The counterweight size changes as float rod is lengthened.

Consult factory for more information.

3. Set Float High Level Shut-Off. Move float rod to "up" position. Adjust the upper stop collar on the float rod

assembly approximately three inches above the desire high water level. Move float rod to "down" position.

Adjust the lower stop collar on the float rod assembly approximately three inches below the desired low water

level. Tighten collar set screws.

4. If the closing level is too high, allowing tank to overflow, then the top stop collar on the float rod should be

lowered. If the opening level is too low, then the bottom stop collar should be raised.

If the counterweight has been properly adjusted the float will move freely on the float rod, without causing the

pilot arm to raise or lower, until the float actually contacts one of the stop collars.

5. For reference: with a new control and supply pressure less than 40 psi the maximum level differential avail-

able will be: 18 to 20 inches with PVC float and rod assembly and 48 to 50 inches with Stainless Steel or Brass

float and rod assembly.

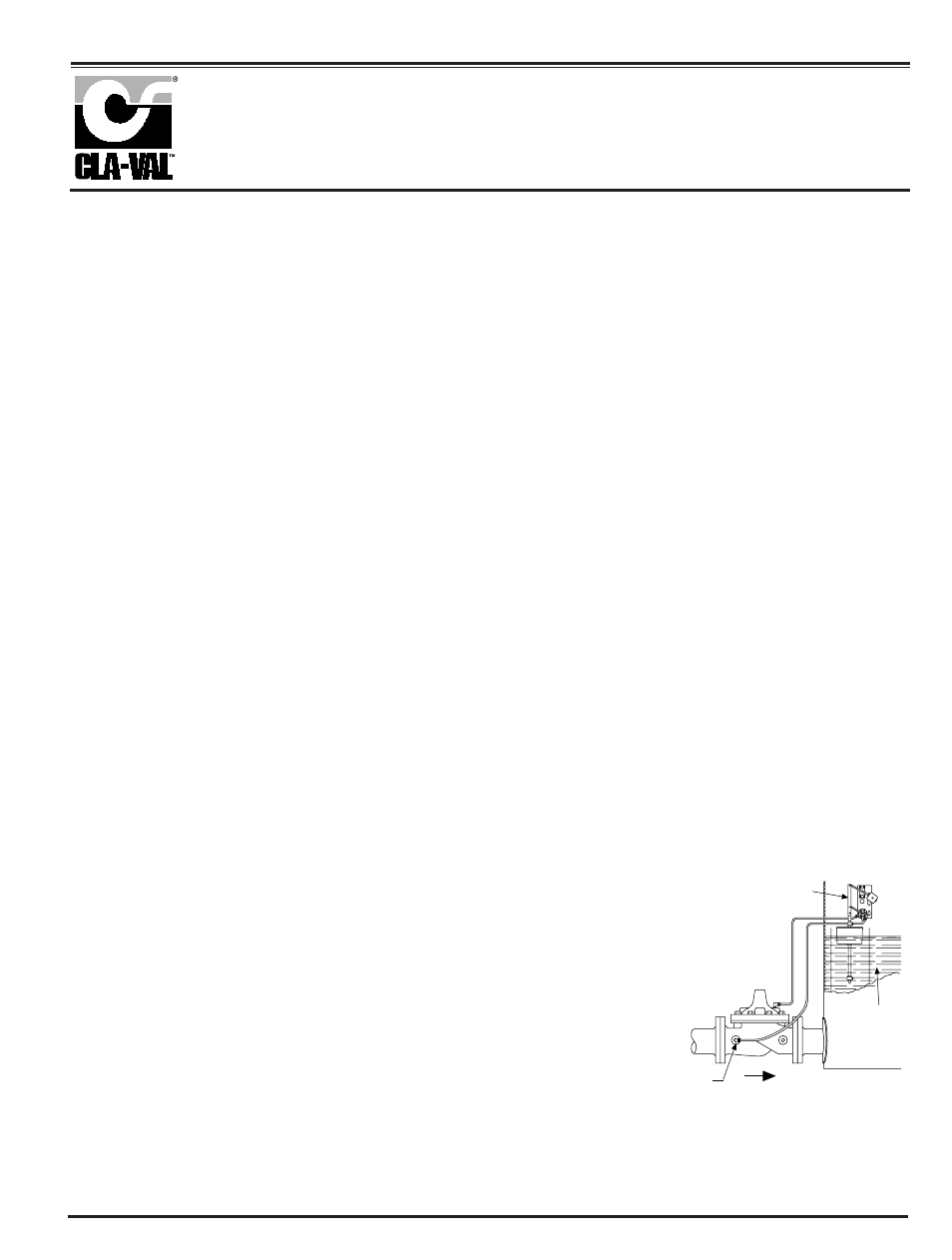

Installation Data

The float control is mounted above the

high water level in the tank. The valve is

installed in the line leading to the tank

and is connected to the float control

pilot by tubing. (Min. 3/8" tubing)

When line pressure is used to operate

the valve, tubing connections are made

from the float control pilot to the valve

cover, and also to the inlet side of the

valve. An X43 “Y” Strainer or X46 Flow

Clean Strainer must be installed in the

inlet side of the valve. The control may

be installed at any elevation above the

valve, providing that the flowing line

pressure in psi is equal to, or greater

than, the vertical distance in feet

between the valve and the float control.

An independent source of air or water

may be used to operate the valve. The

pressure from this independent source

must constantly be equal to or greater

than pressure at the valve inlet. The

independent source is connected to the

float control pilot in place of the supply

line connected to the inlet side of the

valve. If the Model 100-01 under the

control of the CF1-C1 is 8" or larger,

auxiliary Hytrols may be required.

Consult factory for details.

NOTE:

A stilling well (Min. 8" I.D.) must be pro-

vided around the float if the liquid surface

is subject to turbulence, ripples or wind.

Stilling

Well

Flow

CF1-C1

X43 or

X46

Strainer

Note: We recommend protecting Float Control tubing and valve from freezing temperatures.