E-90-72_2, Model 90-72, Dimensions – Cla-Val 90-72/690-72 User Manual

Page 2: Model 90-72 dimensions, Materials, Pressure ratings

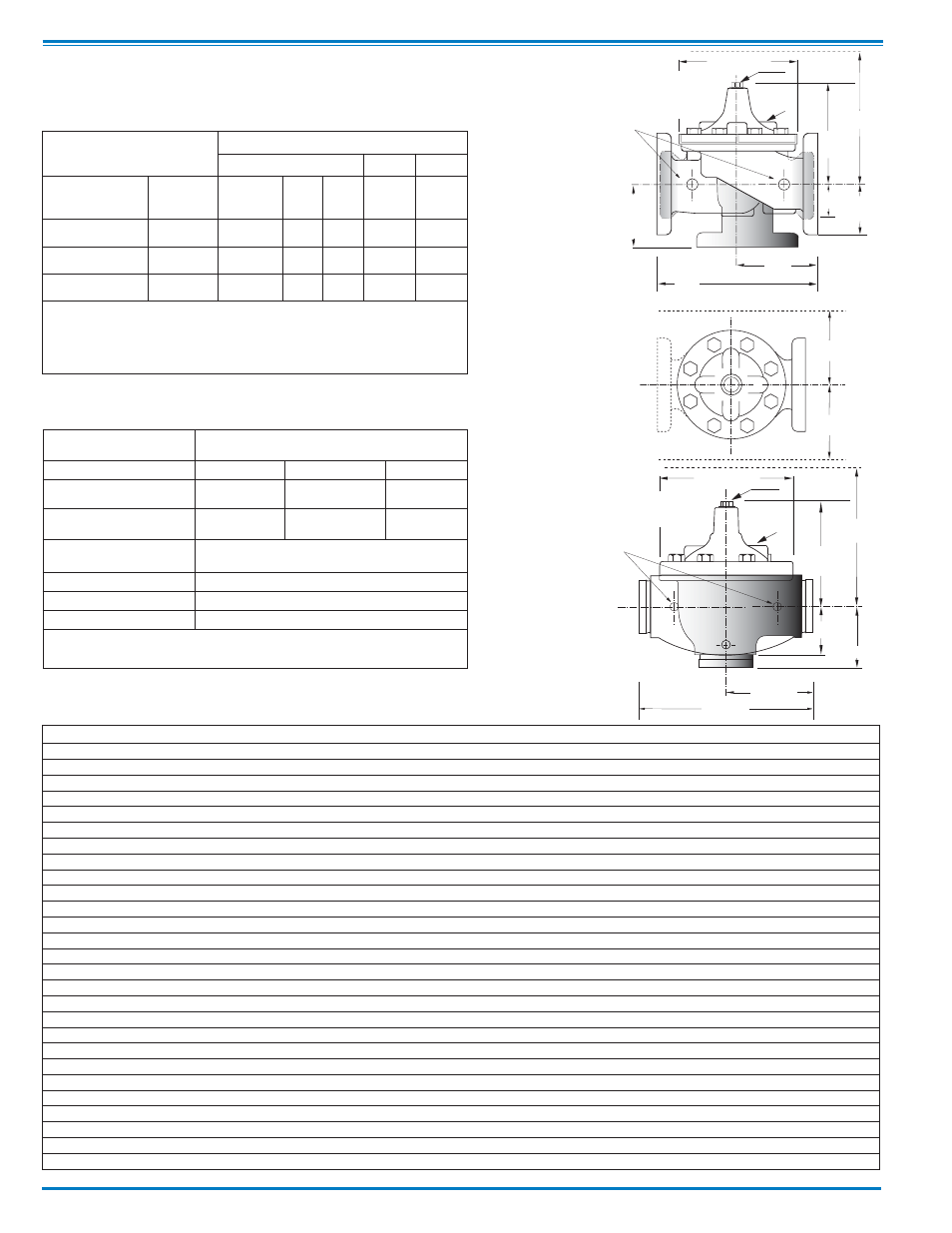

Model 90-72

(Uses Basic Valve Model 100-01)

Dimensions

(In inches)

Model 90-72 Dimensions

(In Inches) - For larger sizes, consult Factory

Component

Standard Material Combinations

Body & Cover

Ductile Iron

Cast Steel

Bronze

Available Sizes

1" - 8"

1" - 8"

1" - 8"

Disc Retainer &

Diaphragm Washer

Cast Iron

Cast Steel

Bronze

Trim: Disc Guide,

Seat & Cover Bearing

Bronze is Standard

Stainless Steel is Optional

Disc

Buna-N

®

Rubber

Diaphragm

Nylon Reinforced Buna-N

®

Rubber

Stem, Nut & Spring

Stainless Steel

For material options not listed, consult factory.

Cla-Val manufactures valves in more than 50 different alloys.

Materials

GGGG

DDDD

Inlet

AAAA

X

100-01

Grooved

EE

CC

(MAX)

K

J

H

Inlet

Outlet

B

(Diameter)

Y

Z

G

GG

GGG

D

Inlet

DD

DDD

F

FF

X

100-01

Threaded &

Flanged

A

E

C

(MAX)

K

J

H

Inlet

Outlet

AA

AAA

B

(Diameter)

Valve Body & Cover

Pressure Class

Flanged

Grooved Threaded

Grade

Material

ANSI

Standards*

150

Class

300

Class

300

Class

End‡

Details

ASTM A536

Ductile Iron B16.42

250

400

400

400

ASTM A216-WCB Cast Steel

B16.5

285

400

400

400

ASTM B62

Bronze

B16.24

225

400

400

400

Note:

* ANSI standards are for flange dimensions only.

Flanged valves are available faced but not drilled.

‡ End Details machined to ANSI B2.1 specifications.

Valves for higher pressure are available; consult factory for details

Pressure Ratings

(Recommended Maximum Pressure - psi)

Valve Size (Inches)

1

1

1/4

1

1/2

2

2 1/2

3

4

6

8

A Threaded

7.25

7.25

7.25

9.38

11.00

12.50

—

—

—

AA 150 ANSI

—

—

8.50

9.38

11.00

12.00

15.00

20.00

25.38

AAA 300 ANSI

—

—

9.00

10.00

11.62

13.25

15.62

21.00

26.38

AAAA Grooved End

—

—

8.50

9.00

11.00

12.50

15.00

20.00

25.38

B Dia.

5.62

5.62

5.62

6.62

8.00

9.12

11.50

15.75

20.00

C Max.

5.50

5.50

5.50

6.50

7.56

8.19

10.62

13.38

16.00

CC Max. Grooved End

—

—

4.75

5.75

6.88

7.25

9.31

12.12

14.62

D Threaded

3.25

3.25

3.25

4.75

5.50

6.25

—

—

—

DD 150 ANSI

—

—

4.00

4.75

5.50

6.00

7.50

10.00

12.69

DDD 300 ANSI

—

—

4.25

5.00

5.88

6.38

7.88

10.50

13.25

DDDD Grooved End

—

—

—

4.75

—

6.00

7.50

—

—

E

1.12

1.12

1.12

1.50

1.69

2.06

3.19

4.31

5.31

EE Grooved End

—

—

2.00

2.50

2.88

3.12

4.25

6.00

7.56

F 150 ANSI

—

—

2.50

3.00

3.50

3.75

4.50

5.50

6.75

FF 300 ANSI

—

—

3.06

3.25

3.75

4.13

5.00

6.25

7.50

G Threaded

1.88

1.88

1.88

3.25

4.00

4.50

—

—

—

GG 150 ANSI

—

—

4.00

3.25

4.00

4.00

5.00

6.00

8.00

GGG 300 ANSI

—

—

4.25

3.50

4.31

4.38

5.31

6.50

8.50

GGGG Grooved End

—

—

—

3.25

—

4.25

5.00

—

—

H NPT Body Tapping

.375

.375

.375

.375

.50

.50

.75

.75

1

J NPT Cover

Center Plug

.25

.25

.25

.50

.50

.50

.75

.75

1

K NPT Cover Tapping

.375

.375

.375

.375

.50

.50

.75

.75

1

Stem Travel

0.4

0.4

0.4

0.6

0.7

0.8

1.1

1.7

2.3

Approx. Ship Wt. Lbs.

15

15

15

35

50

70

140

285

500

X Pilot System

11

11

11

13

14

15

17

29

31

Y Pilot System

9

9

9

9

10

11

12

20

22

Z Pilot System

9

9

9

9

10

11

12

20

22