Cla-Val 34AR Series User Manual

Page 3

MAINTENANCE

The simple and compound Air Release Valves (ARV)

require no regular lubrication or maintenance.

A Periodic inspection to verify operation can be performed.

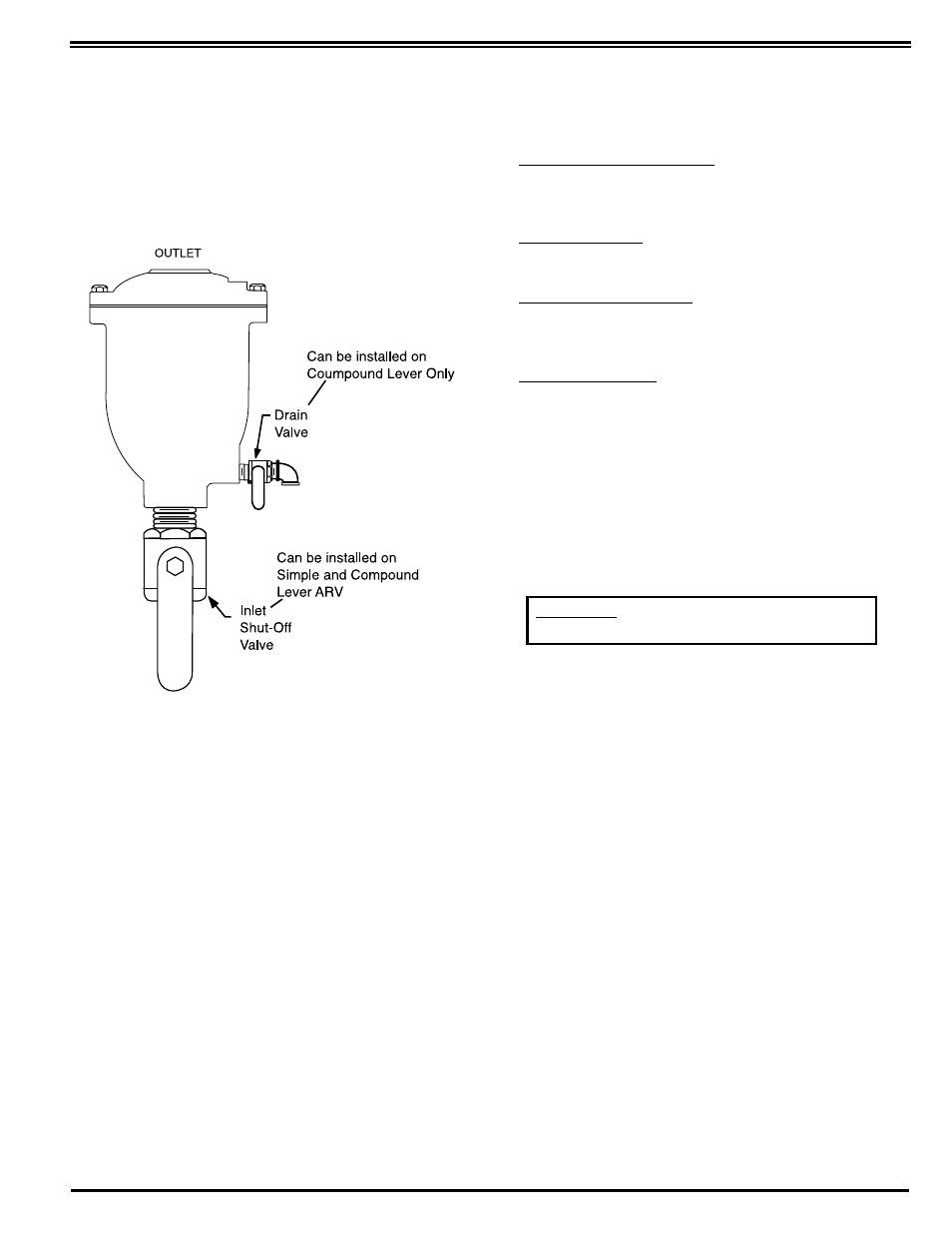

A manual drain valve can be installed in place of the lower

drain plug (14 - Fig. 2) to perform this operation as shown in

Figure 3.

1. Partially open inlet shut off valve until water flow is

visible. This will indicate the ARV is working properly. If

only air flow observed is follow steps 2-6.

2. Close inlet shut-off valve.

3. Slowly open drain valve to allow fluid in ARV to drain. If

draining is difficult, the orifice may be clogged (valve

requires service).

4. Close drain valve.

5. Slowly crack open inlet shut-off valve to fill ARV with fluid.

Observe the seating action and verify that valve closes

without leakage.

6. If leakage occurs, remove ARV to inspect internals for

wear or damage from foreign objects.

PROBLEMS

Solutions, presented below, will assist you troubleshooting

the ARV assembly in an efficient manner.

•

Leakage at Inlet Connection: Tighten valve threaded

connection. If leaks persists, remove valve and seal

threads with pipe sealant.

•

Leakage at Cover: Tighten bolts per Table 2, or replace

cover gasket.

•

ARV Leaks when Closed: Flush ARV to remove debris.

Disassemble and inspect seat, orifice button, for damage

and float for water content.

•

ARV not Venting Air: Check that system operating

pressure does not exceed Working Pressure on ARV

nameplate. Inspection per steps 2-6 and disassemble

valve if problems persists.

DISASSEMBLY

Work on the ARV Should be one by a Qualified Mechanic

The ARV can be disassembled without removing it from the

pipeline. Or for the ARV can be removed from the line. No

special tools are required to make repairs.

1. Close inlet shut-off valve. Open drain valve or slowly remove

drain plug. Remove the cover bolts (7) from top cover

2. Pry cover (2) loose and lift off ARV body.

3. Remove the 2 retainer rings (13) and pivot pins (12) that

pass through the lever frame (3). The float (5) and linkage will

be free from the cover. Disconnect float from lever (10).

4. To remove lever frame (3), remove two rounded-head

fasteners (8). Rotate seat (4) counter-clockwise to remove.

5. Remove locknut (18) and orifice button (11) from orifice

button arm (22).

6. Clean and inspect parts. Note: some floats contain sand

for required weight; if water is detected, replace float.

Replace worn parts as necessary and lubricate parts with

food grade grease.

WARNING: The valve must be depressurized

before taking the cover off.

FIG. 3 INSPECTION