Cla-Val 36 Series User Manual

Page 5

MAINTENANCE: Arrestor checks require no schedule

maintenance. Flow thru this valve is adjustable. should the

float in the air valve slam shut due to the water flow, plug

up the tapped holes of the disc with standard fastener and

lockwashers until the desired non-slam is achieved.

DISASSEMBLY:

The arrestor check must be disconnected from the air

vacuum valve for disassembly

WARNING:

Drain the valve before unbolting the

flanged or internal pressure may cause injury.

1. Close main isolation valve. Drain air/vacuum valve

and remove from top of anti-slam valve. Replace

gasket if damaged.

2. Unbolt air/vacuum valve and remove from top of

anti-slam valve. Replace gasket if damaged.

3. Remove small seat fastener on flange face.

4. Lift seat, disc and spring from valve body. 14” and

larger valves do not have spring.

5. Clean and inspect parts for wear.

Replace parts if worn or damaged. During reassembled,

tighten flange bolts with the “Max. Torque” values given

in table 1.

PARTS AND SERVICE

Parts and service are available from your local repre-

sentative or the factory. Make note of the valve size and

model no. located on the valve nameplate and contact

CLA-VAL

A sales representative will quote prices for parts or

arrange for service as needed.

ITEM

1

2

3

4

5

6

7

DESCRIPTION

Body

Seat

Disc*

Spring (4” - 12”)

Bushing

Seat Ret. Screw*

Retainer Nut*

MATERIAL

Cast Iron

Bronze

Bronze

Stainless Steel

Brass

Stainless Steel

Brass

* Recommended Spare Part List

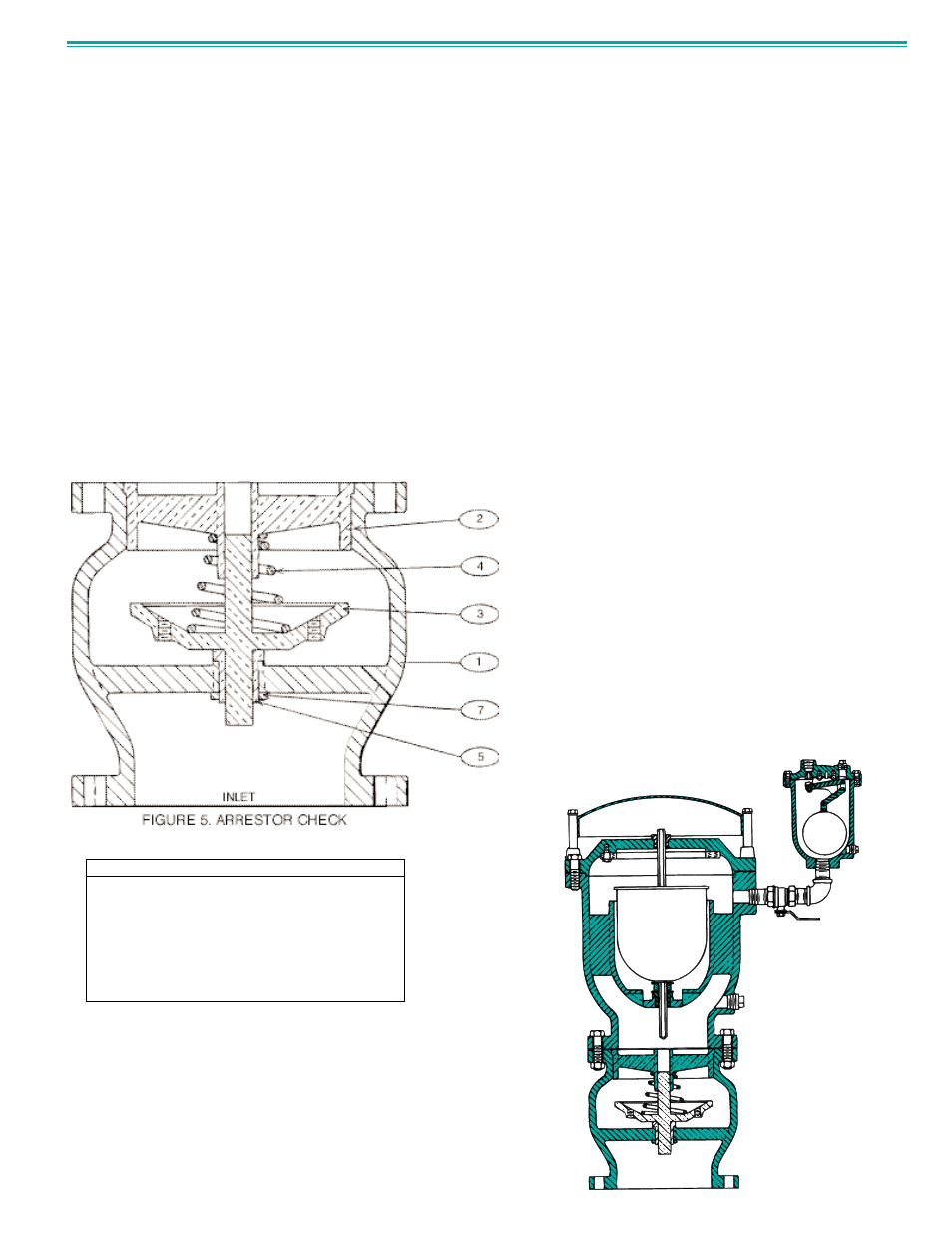

TABLE 4. ARRESTOR CHECK PARTS LIST

OPTIONAL ARRESTOR CHECK OPERATION

Air/Vacuum Valves may be factory or field equipped with

an arrestor check on the inlet port as shown in Figure 4.

The function of the arrestor check is to protect the air/vac-

uum valve from slam shock, resulting from instant pipeline

flow stoppage.

The arrestor check is normally open, allowing unrestricted

flow of air in and out of the air/vacuum valve. But, when

high velocity water enters the valve, the force raises the

disc to its closed position and the flow of water is throttled

through small ports in the disc to reduce shock closure and

water hammer.

The standard valve body material is cast iron with bronze

disc. General details of construction are illustrated in figure

5. The body (1) is flanged for connection to the pipeline.

See page 2 for installation to the pipeline.