Cla-Val 36 Series User Manual

Page 2

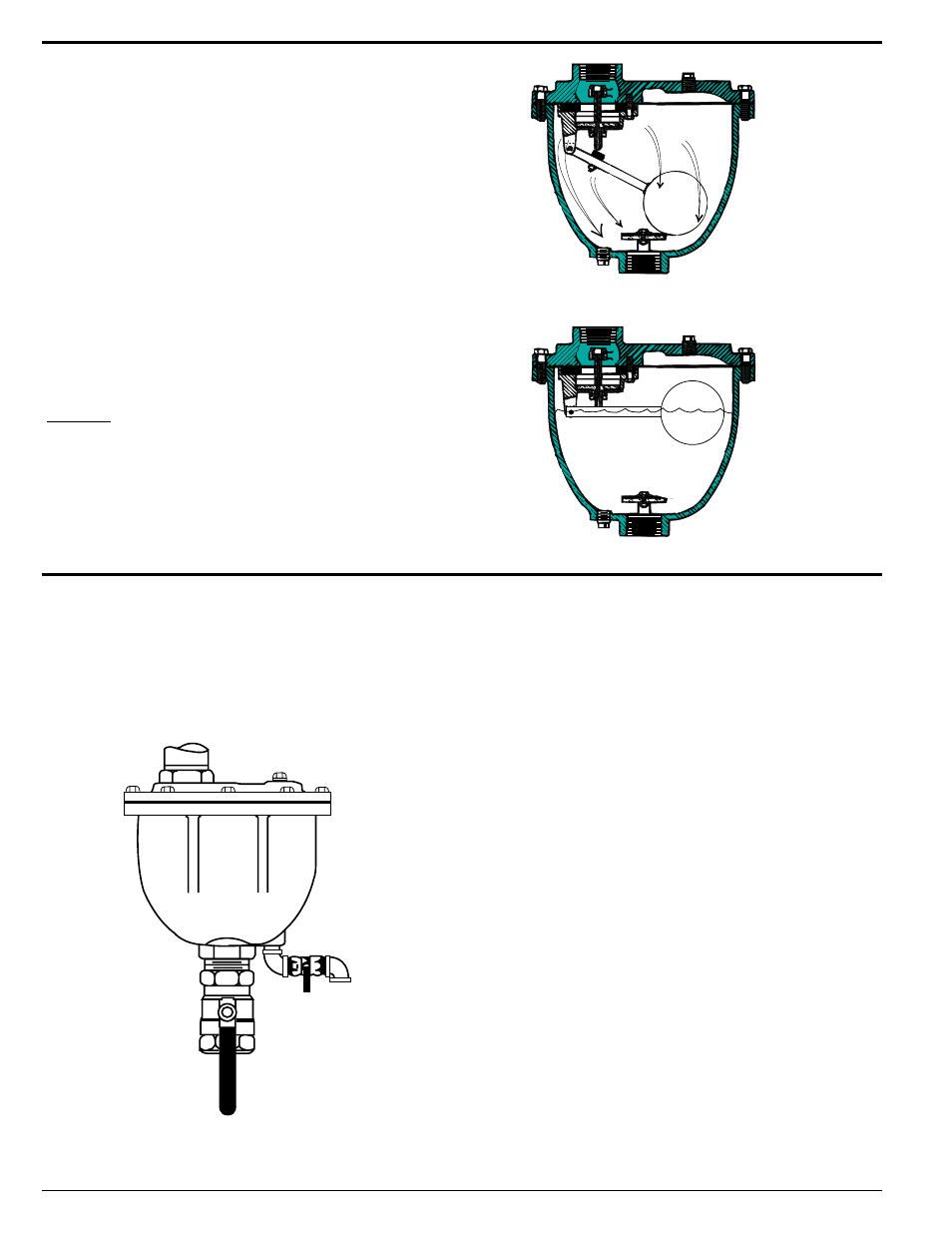

When the system is drained, the plug will reopen allowing air

to rapidly re-enter the piping system. See Figure 4.

3.

Figure 4. Air Enters

During Pipeline

Draining

INLET

At other times the valve is closed and under pressure as shown

in Figure 5.

Figure 5. Pipeline

Under Normal

Pressure

INLET

INSTALLATION

The installation of the valve is important for its proper operation.

Valves must be installed at the system high points in the vertical

position with the inlet down. For pipeline service, a vault with

freeze protection, adequate screened venting, and drainage

should be provided. During closure, some fluid discharge will

occur so vent lines should extended to an open drain area in

plant services. A shut-off valve should be installed below the

valve in the event servicing is required.

CAUTION: Installed valve with “INLET” port down or

leakage will occur.

MAINTENANCE

The Combination Air Valve requires no scheduled lubrication or

maintenance.

INSPECTION: Periodic inspection to verify operation can be per-

formed. A manual drain valve can be installed in the lower drain

plug to plug to perform this operation as shown in Figure 7.

FIGURE 7. INSPECTION PIPING

With the inlet shut-off valve open, partially open the drain

valve until flow can be heard. If the air valve is working prop-

erly, water should be exhausted from the drain valve. If air is

exhausted, follow steps 2-6.

1.

Close the inlet shut-off valve.

2.

Slowly open the drain valve to allow the fluid in the valve to

drain. If draining is difficult, the valve may be clogged (valve

requires service).

3.

Close the drain valve

4.

Slowly open the inlet shut-off valve to fill the valve with water.

Observe the seating action and verify that the valve closes

without leakage.

5.

If leakage occurs, the valve should be removed and inspect-

ed for water or possible damage from foreign matter.

6.