Cla-val, Air v alves, Backflushing procedures – Cla-Val 34WW Series User Manual

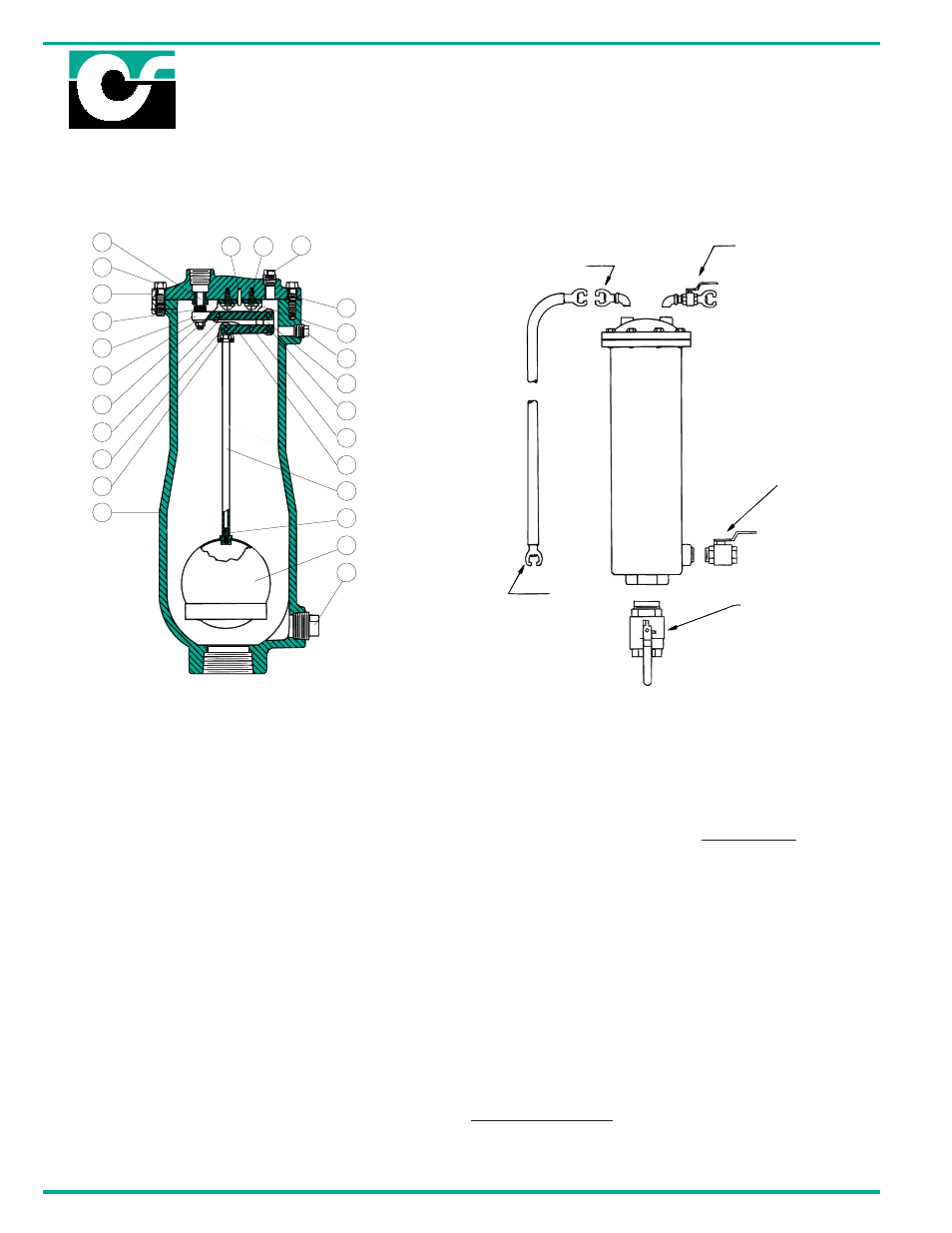

Page 2: Valve d valve e valve b c valve a

¤

“

Air V

alves

CLA-VAL

19

12

13

10

20

17

5

28

14

4

7

2

11

22

34

18

3

33

35

1

21

8

14

30

6

Flow

Sensitive

Skirt

Valve

D

Valve

E

Valve

B

C

Valve

A

RUBBER HOSE

WITH QUICK

DISCONNECT COUPLING

ON EACH END.

Part No.

Part Name

Material

1

Body

Cast Iron ASTM A126, Class B

2

Cover

Cast Iron ASTM A126, Class B

3

Leverage Frame

Stainless Steel T304, ASTM A240

4

Seat

Stainless Steel T303, ASTM A276

5

Float

Stainless Steel T304, ASTM 240

6

Gasket

Lexide NK-511 (non-Asbestos)

7

Cover Bolt

Alloy Steel ASTM A449, Grade 5

8

Retaining Screws

Stainless Steel T303, ASTM A276

10

Float Arm

Stainless Steel T303, ASTM A276

11

Orifice Button

Stainless Steel & Buna-N

®

12

Pivot Pin

Stainless Steel T303, ASTM A276

13

Retaining Ring

Stainless Steel PH 15-7 Mo

14

Pipe Plug

Carbon Steel

17

Float Retainer

Stainless Steel, ASTM T18-8 A276

18

Lock Nut

Stainless Steel T304, ASTM A276

19

Link

Stainless Steel T304, ASTM A240

20

Guide Shaft

Stainless Steel T304, ASTM A269

21

Location Pin

Stainless Steel T420

22

Orifice Button

Stainless Steel T303, ASTM A276

28

Pipe Plug

Carbon Steel

30

Washer

Stainless Steel T18-8, ASTM A240

33

Clevis

Stainless Steel T304, ASTM A240

34

Lock Washer

Stainless Steel T304, ASTM A240

35

Retaining Screw

Stainless Steel T304, ASTM A240

BACKFLUSHING PROCEDURES

Backflushing steps are basically the same for all sizes and

styles of wastewater Air Release, Air and Vacuum and

Combination Valves and this can be accomplished in two

ways.

1. With clean water, that must be 15 PSI higher than the

pressure in the force main, the valve may be flushed clean

back into the force main. Flush back into the force main by

connecting hose C to valve D. Next open valve A and flush

for 2-3 minutes thru D. Next close D and switch hose C to

E and flush for one minute. After flushing close valve A.

Disconnect hose C and vent pressure inside the Air Valve

thru valve D. Next remove cover bolts (det 7.) remove top

cover (det 2) for visual inspection and scrape out any

grease. Use care to remove the cover and the cover gas-

ket (det 3) may be re-used many times. Reinstall cover

(det. 2) and slowly open valve A.

2. With clean water that is not 15 psi higher pressure than

the force main, backflush thru valve B into an atmospheric

collection tank. Follow the same procedure as above

except close valve A and open valve B. After flushing

remove cover to inspect interior and replace cover same

as above. Then close valve B, open valve A and the waste

water valve is back in service.

SERIES 34-WWBK

Waste Water Air Release Valve with Backwash Kit