E-61-02_4, Sequence of operation, Valve selection chart cv values – Cla-Val 61-02KO/661-02KO Valve User Manual

Page 2: Selecting the valve

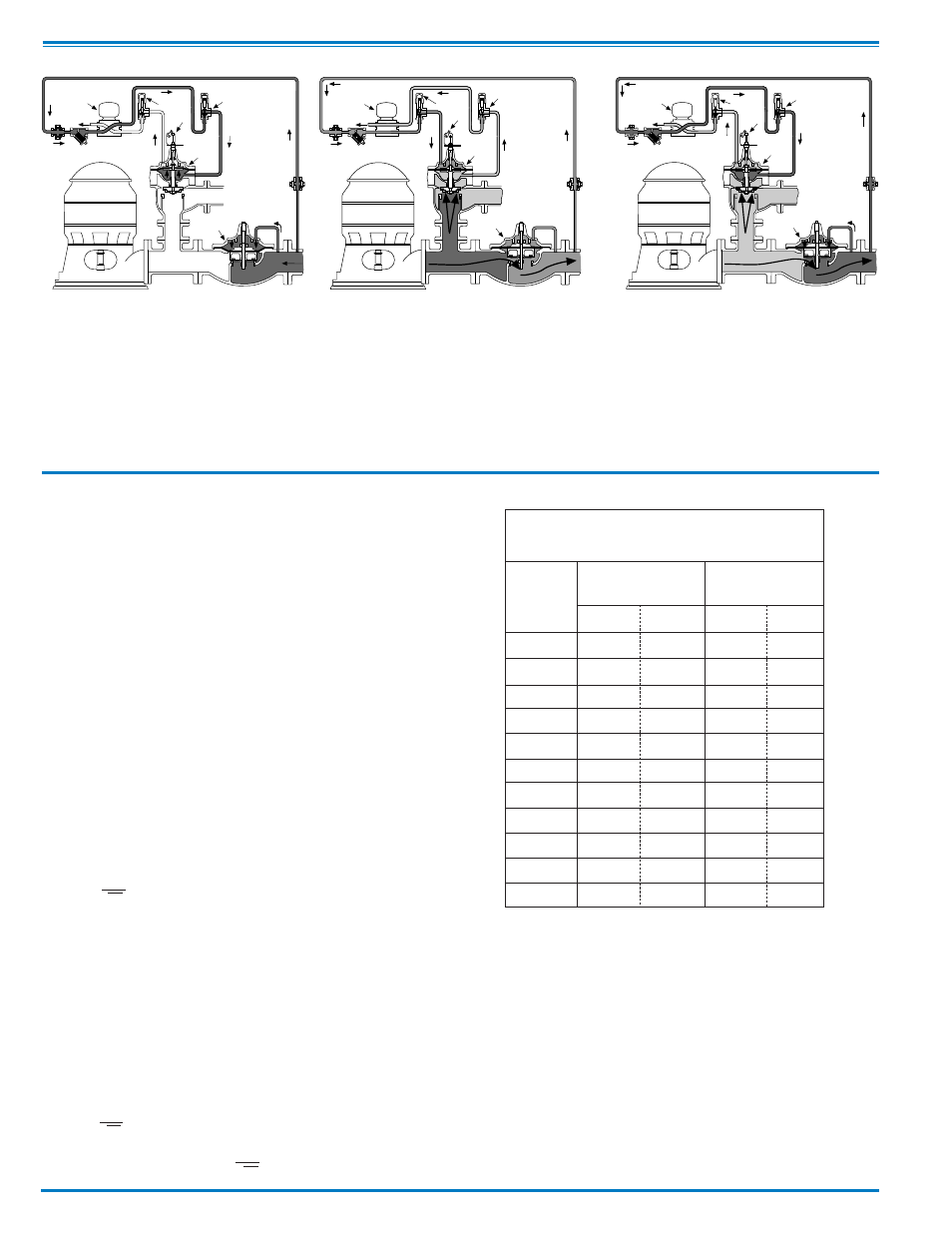

Pump Off...

With pump off, static line pressure holds the

main line check valve “B” closed. Line pres-

sure is transmitted through solenoid control

“C” and speed control “D” to the lower cham-

ber of valve “A”. Upper chamber of pump

control valve “A” is vented to atmosphere so

valve “A” is held wide open.

Starting Cycle...

Starting switch closes, pump starts, solenoid

“C” energizes and shifts, allowing line pressure

to flow into upper chamber of valve “A” through

solenoid control “C” and opening speed control

“E”. Closing speed of valve “A“ is controlled by

speed control “D“ which limits the rate fluid is

relieved from under the diaphragm. As valve

“A” closes, pumping pressure opens main line

check valve “B”, gradually permitting full flow.

Sequence Of Operation

Drain

c

Supply

P.T.1

P.T.2

E

F

D

A

B

Drain

Supply

c

E

F

D

A

B

P.T.1

P.T.2

C

Drain

Supply

P.T.1

P.T.2

E

F

D

A

B

Stopping Cycle...

Starting switch opens, solenoid “C” de-energizes

and shifts, as pump continues to run, pump pres-

sure flows into lower chamber of valve “A” through

solenoid “C” and opening speed control “D”.

Pressure in upper chamber of valve “A” is relieved

to atmosphere through opening speed control “E”

and solenoid control “C”.As valve “A” opens, flow

through main line check valve “B” gradually

lessens until valve “A” is wide open and the limit

switch “F” shuts off the pump.

Valve Selection Chart

Cv Values

Valve

Globe

Angle

Size

61-02

661-02

61-02

661-02

2

1

⁄

2

85

–

101

–

3

115

62

139

–

4

200

136

240

135

6

460

229

541

233

8

770

480

990

545

10

1245

930

1575

–

12

1725

1458

2500

–

14

2300

–

3060

–

16

2940

2110

4200

–

20

–

3400

–

–

24

–

3500

–

–

To be effective, this valve must be sized so it relieves to atmosphere

that part of the pump discharge head which is in excess of the nor-

mal system static pressure. To do this, the valve is sized to permit

the full pump discharge through the valve at a pressure low enough

to keep the system check valve from opening. As the pump control

valve closes, the pumping pressure exceeds the system pressure

and gradually flows into the system.

We recommend selecting a valve size which will have a pressure

loss that is at least 10 psi less than the system static pressure. Use

the flow rate which is found on the pump's flow vs discharge pres-

sure chart. Select the flow corresponding to the system static pres-

sure, less 10 psi.

Determining Valve Size

1. Determine the system's static pressure (the pressure

downstream of the check valve with the pump off); subtract

10 psi, this is the Design Pressure P.

2. From the pump's flow vs. discharge pressure curve,

determine the flow (Q) at the Design Pressure P.

3. Using the formula, calculate the Cv.

Cv =

Q

√ P

4. Select the valve size from the table which has a Cv that is

equal to, or greater than, the calculated Cv in step 3 above.

Example:

1. System Static Pressure with the pump off = 70 psi.

2. Determine the Design Pressure P by subtracting 10 psi

(70 psi - 10 psi = 60 psi Design Pressure)

3. From the pump curve we determine that the valve must

allow a flow of 800 GPM at 60 psi.

4. Using the Formula:

Cv =

Q

Where:

Q = 800 GPM

√

P

P = 60 psi (70 psi - 10 psi)

5. From the table above the best valve choices are:

3"

6 1 - 0 2

Globe Pattern

4"

661-02

Globe Pattern

4"

661-02

Angle Pattern

Drain Provisions

Each time the valve opens or closes, water is dis-

charged from the solenoid exhaust port, the amount

varying with the valve size. Provisions should

be made for the disposal of this water. Exhaust

tube must be free of any back pressure. Provide

an air gap between the solenoid exhaust tube and drain

facility.

Selecting The Valve

Cv =

800

=103

√

60

Example