Cdhs-18, 3/8" differential control, Cla-val – Cla-Val 43-01/643-01 User Manual

Page 18: Model installation / operation / maintenance

DESCRIPTION

The Cla-Val CDHS-18 Differential Control Valve is a normally open,

spring loaded, diaphragm type valve that operates hydraulically and is

designed to close on a rising differential pressure. When used as a pilot

control with Cla-Val Valves, it acts as a flow limiting control.

INSTALLATION

The Differential Control may be installed in any position. There is one

inlet port and two outlet ports in the body for either straight or angle

installation. The outlet port senses the high pressure or inlet to the differential

producing device. One of the outlet ports can be used for a gauge

connection. The port above the diaphragm (located in the control cover)

is used to sense the low pressure or outlet side of the differential producing

device. A flow arrow is marked on the body casting.

OPERATION

The Differential Control is normally held open by the compression spring

and the sensing pressure above the diaphragm. When the rate of flow

through the main valve increases, the sensing pressure above the

diaphragm of the control decreases and the higher pressure at the outlet

port closes the control; which, in turn, closes the main valve. When the

rate of flow through the main valve decreases, the sensing pressure

above the diaphragm increases. This opens the control and in turn

opens the main valve. This action causes the main valve to modulate,

limiting the flow rate to the setting of the control.

ADJUSTMENT

The Differential Control Valve can be adjusted to limit the rate of flow as

specified on the data plate. Rate of flow adjustment is made by turning

the adjustment screw to vary the spring pressure on the diaphragm. The

greater the compression on the spring the higher the flow rate.

1. Turn the adjustment screw in (clockwise) to increase flow rate.

2. Turn the adjustment screw out (counterclockwise) to decrease flow

rate.

DISASSEMBLY

The Differential Control Valve should be removed from the Hytrol Valve

assembly. Make sure that pressure shutdown is accomplished prior to

disconnecting assembly. During disassembly inspect all threads for dam-

age or evidence of cross-threading.

NOTE: A bench vice equipped with soft brass jaws should be used to

hold the valve body during disassembly and reassembly. DO NOT tighten

vice jaws more than enough to hold unit firmly. Excessive pressure may

spring or crack casting

1.

Remove adjusting screw cap (16).

2.

Loosen lock nut on adjusting stem assembly (9) and turn

adjusting screw counterclockwise to relieve tension on spring.

3.

Remove bottom plug (8) and gasket (6).

4.

Remove disc retainer assembly (5) and inspect sealing surface for

damage or wear. Replace if necessary.

5

Remove 8 screws (12) and carefully Iift off cover (2) spring guide

(10)

and spring (13) can now be removed.

6.

Remove diaphragm assembly.

7.

Remove diaphragm nut (7) and diaphragm washer (4).

8.

Remove diaphragm (3), inspect for damage and replace if neces-

sary.

9.

Inspect all parts for damage, corrosion, wear, foreign particles, and

cleanliness.

10. Repair minor nicks and scratches, these may be polished out

using a fine grade of emery or crocus cloth.

REASSEMBLY

Prior to reassembly replace all parts which are damaged or worn. When

ordering replacement parts be sure to specify item, part number, and all

nameplate data.

1.

Place diaphragm (3) on top of yoke (11) place diaphragm

washer (4) over diaphragm with rounded edges down or next

to diaphragm. Screw on diaphragm nut (7) with the spring

guide shoulder in up position. The nut is not tightened at this time.

2.

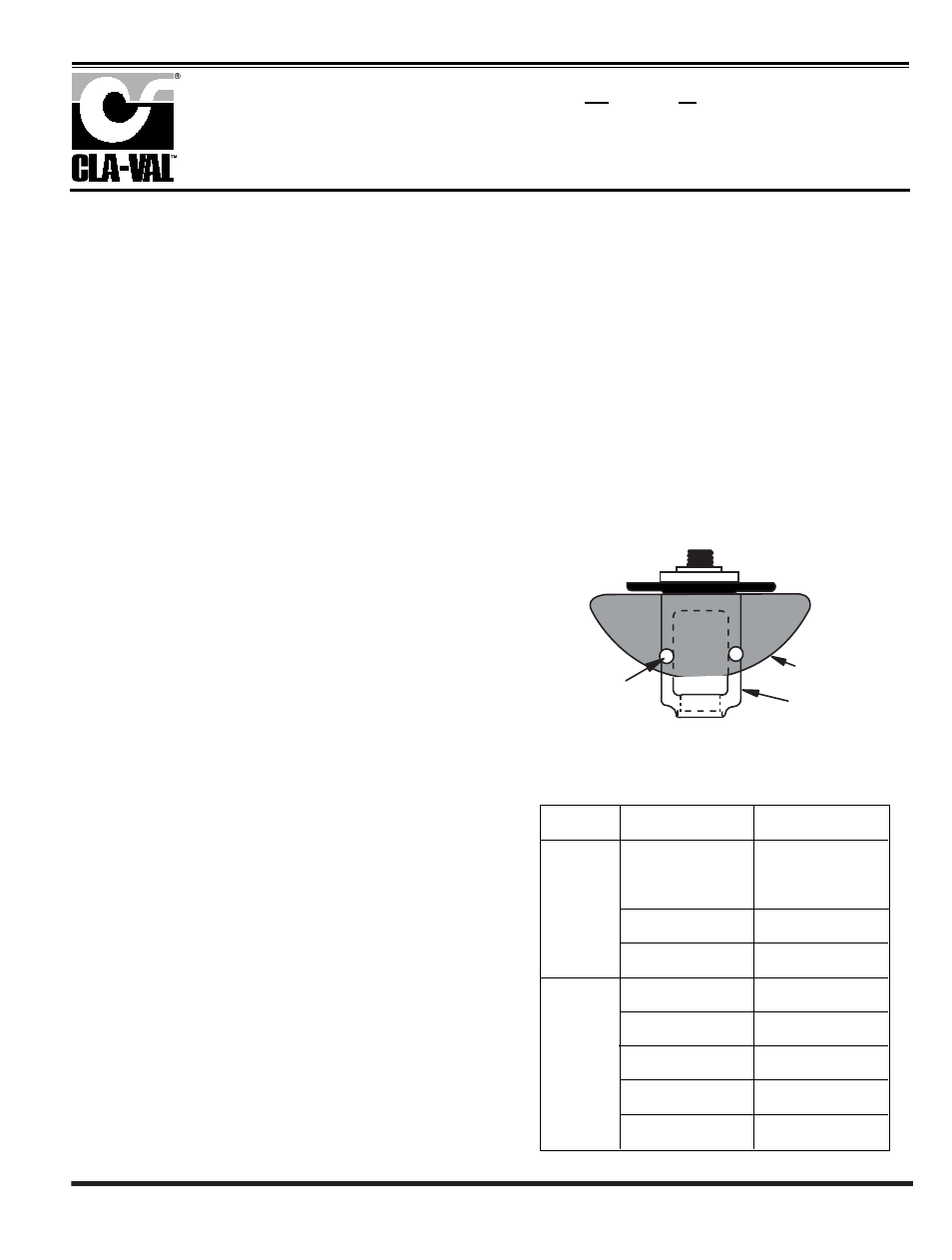

Align diaphragm flange holes with and folding diaphragm as

shown. Tighten diaphragm nut, retaining alignment shown.

3.

Place yoke assembly in body (1) and screw the disc retainer

assembly (5) in until it bottoms.

4.

Screw in plug (8).

NOTE: The yoke arms can be viewed through the 3/8" NPT

high pressure sensing outlet. There should be even spacing

between the yoke arms and the 3/8' NPT inlet boss seat

assembly. There must be no drag or friction between these

parts. If there is drag, repeat step 2.

5.

Align diaphragm flange holes with the body holes and position

spring and spring guide (13) (10).

6.

Replace cover (2) and secure with 8 screws (12).

7.

Remove plug (8) and turn adjusting screw clockwise until the

disc retainer assembly moves down.

8.

Replace gasket (6) and plug (8).

9.

Replace cap (16).

3/8" Differential Control

CDHS-18

DIAPHRAGM

HOLES

DIAPHRAGM

YOKE

DIAPHRAGM HOLE ALIGNMENT

F

AILS TO

O

PEN

C

ONTROLLING DIFFERENTIAL

NOT CHANGING

C

HECK WITH GAUGE OR

MANOMETERS

D

IAPHRAGM ASSEMBLY STUCK

CLOSED

D

ISASSEMBLE AND FREE

F

OREIGN OBJECT UNDER

DISC RETAINER

D

ISASSEMBLE AND REMOVE

F

AILS TO

C

LOSE

I

NSUFFICIENT CONTROLLING

DIFFERENTIAL

I

NCREASE DIFFERENTIAL

F

OREIGN OBJECT UNDER

DISC

D

ISASSEMBLE AND REMOVE

D

ISPHRAGM ASSEMBLY STUCK

OPEN

D

ISASSEMBLE AND FREE

D

AMAGED DIAPHRAGM

D

ISASSEMBLE AND REPLACE

S

PRING COMPRESSED SOLID

B

ACK OFF ADJUSTING STEM

SYMPTOM

PROBABLE CAUSE

REMEDY

N

O SPRING COMPRESSION

S

CREW IN ADJUSTING STEM

SERVICE SUGGESTIONS

MODEL

INSTALLATION / OPERATION / MAINTENANCE

CLA-VAL

Copyright Cla-Val 2008 Printed in USA Specifications subject to change without notice.

P.O. Box 1325

• Newport Beach, CA 92659-0325 • Phone: 949-722-4800 • Fax: 949-548-5441 • E-mail: [email protected] • Website cla-val.com

©

N-CDHS-18 (R- 1/08)