Ii. low pressure override feature, Iii. x78-4 adjustable orifice assembly feature, Iv. accumulator feature – Cla-Val 98-06/698-06 Quick Manual User Manual

Page 3: V. 6120 needle valve feature, Vi. optional feature operating data, X78-4 adjustment table

II. LOW PRESSURE OVERRIDE FEATURE

To override an established low pressure set point of the CPM-A (4),

open Isolation Valve (6B). Low pressure set point is disabled and Main

Valve (1) regulates at the high pressure set point as long as the

Isolation Valve (6B) remains open. To restore the low pressure set

point condition, close Isolation Valve (6B).

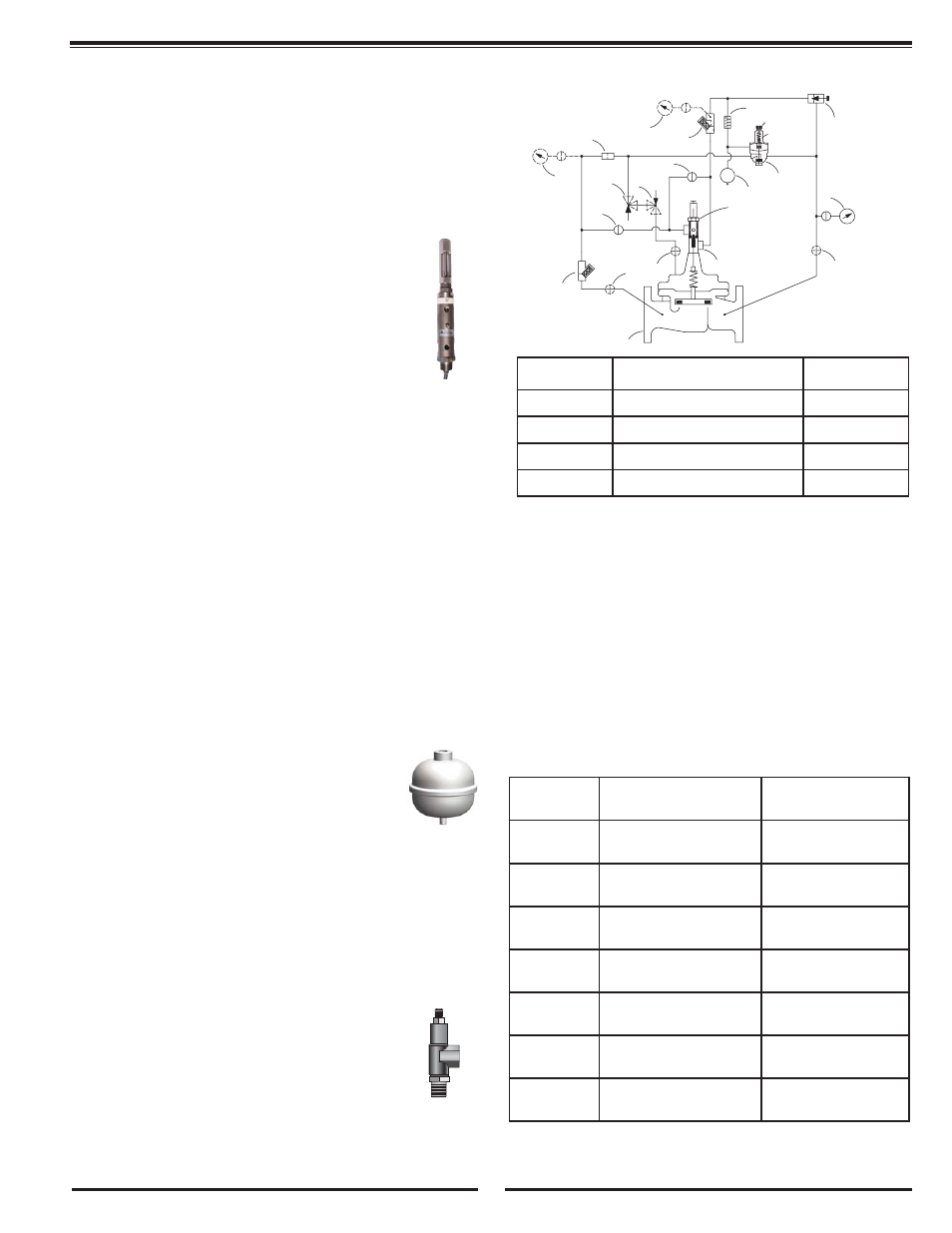

III. X78-4 ADJUSTABLE ORIFICE ASSEMBLY FEATURE

The Adjustable Orifice Assembly is comprised of the

X78-4 Adjustable Orifice + the X101 Valve Position

Indicator.

The X78-4 Adjustable Orifice Assembly (5) is used to

increase the transition point (% open) between low and

high pressure set points of the CPM-A (4).

Prior to adjusting the X78-4 (5) feature, loosen the set

screw on the side of the X78-4 housing approximately

1/2 turn. The set screw is located near the top of the

X78-4 housing. To lower downstream pressure at the

current (or known) flow rate, turn the X78-4 adjustment screw clockwise

until the pressure reading at the gauge (8) drops to the low pressure set

point of the CPM-A (4). The X78-4 adjustment screw can be turned by

hand or with an open end wrench.

Note:

Adjusting the X78-4 shifts the flow point where the pressure conditions

starts to transition between low and high pressure set points. By turn-

ing the adjustment screw counter-clockwise on the X78-4, the transition

between the low and high pressure set points occurs at a lower flow

rate. As an example: When the X78-4 adjustment screw is turned

counter-clockwise until bottomed, the transition between low and high

pressure set points starts at the lowest possible flow rate. Turning the

X78-4 adjustment screw clockwise changes the transition point to a

higher flow rate. The X78-4 Adjustment Table can be used as a guide-

line to determine valve position change (% open) per turn of the X78-4

adjustment screw.

IV. ACCUMULATOR FEATURE

The Accumulator (11) functions as a pressure transition

dampening device that allows for a relatively smooth

transition between low and high pressure set points of

the Model 98-06/698-06 Pressure Management Valve.

The Accumulator is factory air charged to approximate-

ly 51 psi (3.5 bar). This pre-charge condition is satisfac-

tory for most Model 98-06/698-06 applications and no

additional field charging is required.

If the low pressure set point condition is greater than 80 psi (5.5 bar),

then a slightly higher accumulator air charge pressure may be desir-

able. The accumulator is equipped with a stem valve, similar to a stem

valve used on bicycle or vehicle tires. Air charge pressure can be

changed using a hand tire pump or an air pressure source from a gas

station.

V. 6120 NEEDLE VALVE FEATURE

The 6120 Needle Valve (9) is used to regulate or bal-

ance pressure into and out of the sensing chamber of

the CPM-A Pressure Management Control.

For normal operation, the 6120 Needle Valve is adjust-

ed approximately two turns out. When he 6120 Needle

Valve is turned all the way in, the Main Valve will only

regulate at the high pressure set point of the CPM-A.

When the 6120 Needle Valve is adjusted more than five turns out,

the Main Valve will only regulate at the low pressure set point of

the CPM-A.

VI. OPTIONAL FEATURE OPERATING DATA

Suffix B- Isolation Valve

CK2 Isolation Valves (B) are used to isolate the pilot system from

the main line pressure. These valves must be open during normal

operation.

Suffix C - Closing Speed Control

The CV Flow Control (C) controls the closing speed of the Main

valve. Turn the adjusting stem clockwise to make the Main Valve

close slower.

Suffix S - Opening Speed Control

The CV Flow Control (S) controls the opening speed of the Main

Valve. Turn the adjusting stem clockwise to make the Main Valve

open slower.

X78-4 Adjustment Table

% Position change is the % change in Main Valve opening

per turn of the X78-4 Adjustment Screw.

2

INLET

B

B

6A

P1

S

C

6B

3

7

1

5

9

ADJUSTMENT

HIGH PRESSURE

10

LOW

ADJUSTMENT

PRESSURE

11

4

B

8

ADJUSTMENT SCREW

P2

Model #

Suffix

Item

Quantity

B

CK2 Isolation Valve

3

C

CV Flow Control (Closing)

1

P

X141 Gauge Assembly

2

S

CV Flow Control (Opening)

1

Valve Size

X78-4 (5)

Total Travel

% Position Change

Per Turn

2” 100-01

3” 100-20

.40” (10 mm)

9.9%

2-1/2” 100-01

.40” (10 mm)

8.2%

3” 100-01

4” 100-20

.40” (10 mm)

7.0%

4” 100-01

6” 100-20

.80” (20 mm)

5.3%

6” 100-01

8”100-20

.80” (20 mm)

3.7%

8”100-01

10” 101-20

1.40” (35 mm)

2.6%

10” 100-01

12” 100-20

1.40” (35 mm)

1.8%

3