Advantages applications, Analog signal input, Pulse signal input – Pump Solutions Group Neptune Series PZ_PZi_PZiG Pulse Metering Pumps User Manual

Page 6: Pzi4 / pzi8 / pzig

6

ANALOG SIGNAL INPUT

PZi4 / PZi8 / PZiG

PULSE SIGNAL INPUT

1. Frequency-division (1/1 to 1/9999 adjustable)

Example: 1/6 frequency-division

Signal

Pump operation

2. Multiplication (1 to 9999 adjustable)

Example: 5 times multiplication

(A) Pulses 5 times—next 5 strokes at normal operating speed.

Signal

(B) Pulses 5 times evenly spaced over one minute.

PZi

Conventional products

PZi4 / PZi8 / PZiG

(A)

(B) Injection is more uniform.

1. Proportional band function

The proportional band can be adjusted within a range of ±1% to ±999%.

Pump response to increasing input signal is easily reversed from min. 4mA

and max. flow at 20mA to max. flow 20mA and min. flow at 4mA.

0mA to 20mA range on PZi8 models.

4 (0)

Signal

20mA

0

100%

P

u

m

p

o

p

e

ra

ti

o

n

(A)

(B)

2. Shift function

Shift can be set within the range ±100%

allowing a min. preset flow at 0 (4mA)

signal or allowing no flow until the input

signal exceeds a preset value.

DC4 (0) to 20mA input

4 (0)

12

20

0

300

150

P

u

m

p

st

ro

k

e

(s

p

m

)

Analog input (mA)

200%

100%

999%

50%

1%

30

4.16

4 (0)

12

20

0

300

150

P

u

m

p

st

ro

k

e

(s

p

m

)

Analog input (mA)

–200%

–999%

–50%

–1%

270

4.16

–100%

• Digital settings from 15 to

300 pulses per minute on

PZ models and from 1 to 300

pulses per minute on PZi and

PZD models

• High stroking speed

ensures more uniform

distribution of chemical at

low feed rates

• Pump delivery is constant

at any voltage from 94 to

264 VAC single phase and

is not affected by voltage

fluctuations

• Outdoor use—pump is water

and UV resistant. Equivalent

to IEC specification IP65.

Dust proof, wash down

duty (with proper electrical

connection).

Advantages

Applications

• Injection of chemicals to boilers and cooling towers

• Chlorine sterilization for food plants, small-scale water-supply

systems, buildings and swimming pools

• Injection of nutrients and disinfectants in the livestock industry,

such as poultry and hog producers, as well as for hydroponic

cultivation

• Very low flow rate injection of low viscosity liquids for any

application (100 CPS max. except high viscosity models)

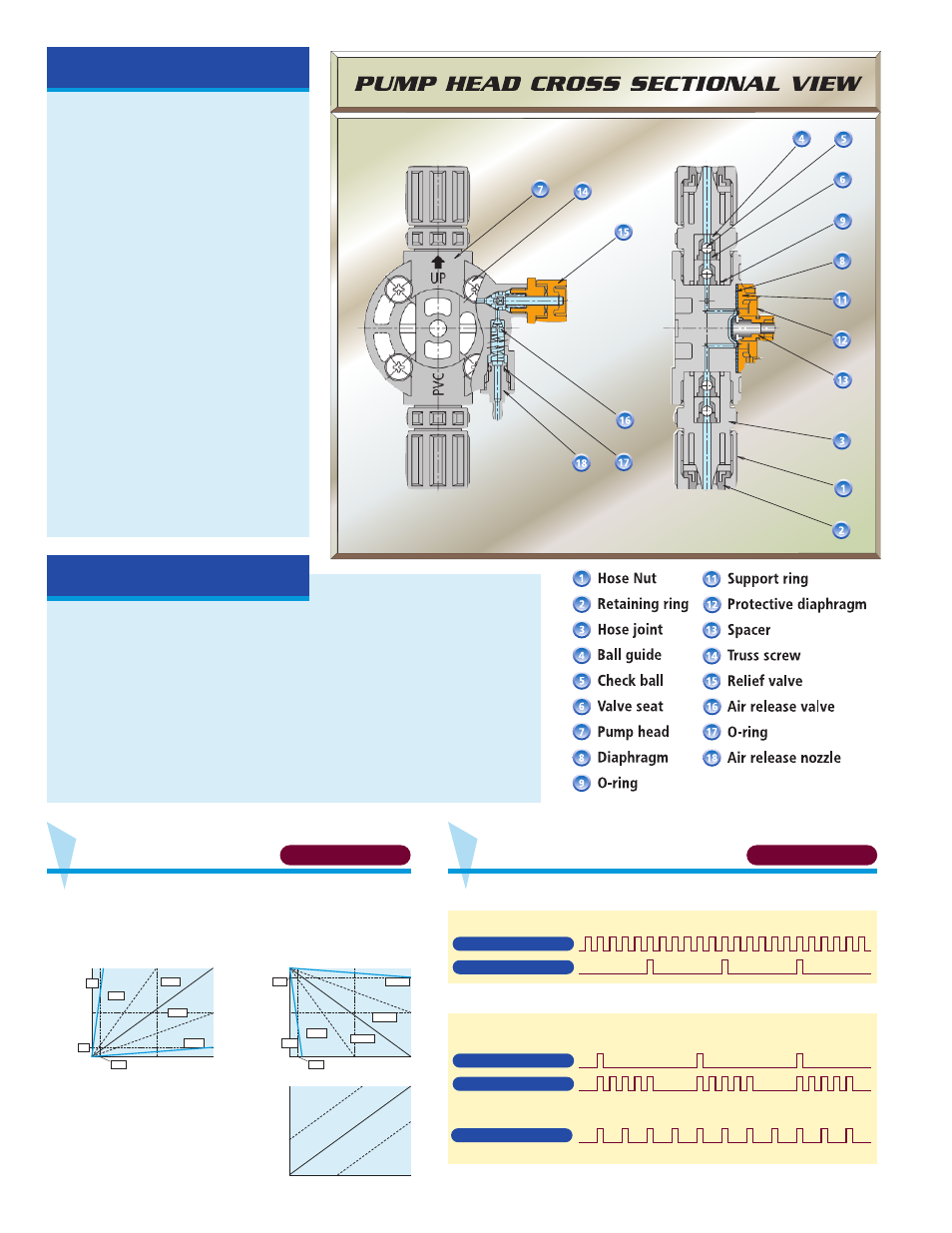

Cross Sectional view applies to PVC, Kynar and Type CL Heads;

does not apply to Material Codes ARPZ, SS or any PZiG Liquid Heads.

Some models use single check balls.