Feed verification, Model fc-1 flow checker, Material selection chart – Pump Solutions Group Neptune Series PZ_PZi_PZiG Pulse Metering Pumps User Manual

Page 5: Caution – all models, Included with each pump

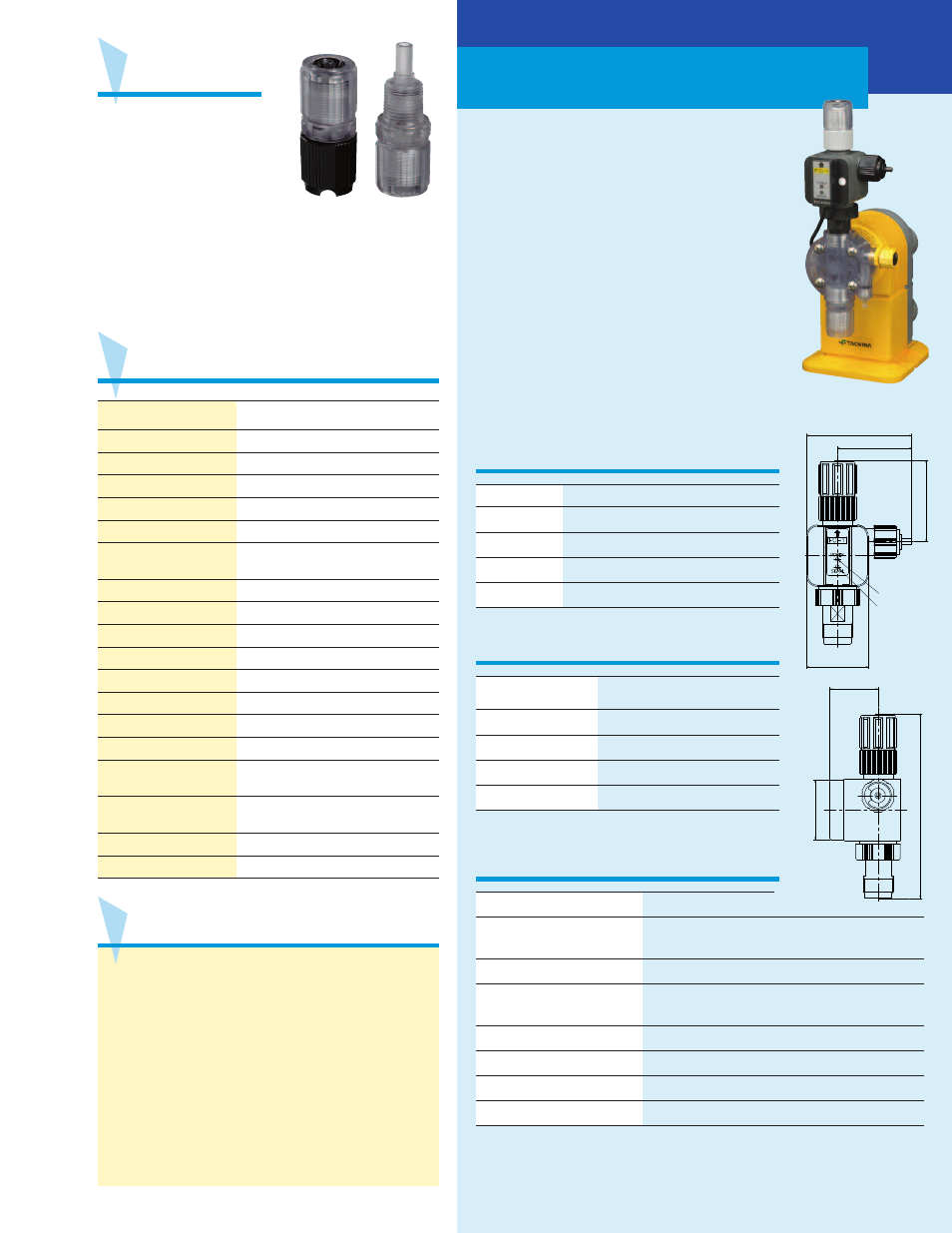

• The flow checker mounts directly to the discharge

of PZ and PZi metering pumps.

• The flow checker is an oval gear flow meter

which measures the pump output and transmits

one pulse for each 1 ml of flow.

• Flow checker output can be connected to

Model PZi8 Pumps for instantaneous indication

of pump output displayed on the pump LCD.

• Connect the flow checker output to your

controller or PLC (external power supply

required if not used with PZi8 type pump).

Feed Verification

Feed Verification

FLOW CHECKER SELECTION CHART

MODEL NO.

MATERIAL

USE w/ PUMP MODEL†

FC-1P-P-N1

Ryton*

PZ or PZi-31

FC-1N-P-N1

Noryl**

PZ or PZi-31

FC-1P-P-N2

Ryton*

PZ or PZi-61 or -12

FC-1N-P-N2

Noryl**

PZ or PZi-61 or -12

† Not available for larger models.

DIMENSIONS

៓

inches (mm)

SPECIFICATIONS

Pulse constant

1mL /pulse

Accuracy

±3% (Depends on nature of chemical,

flow rate, temperature and back pressure.)

Normal operating pressure

140 psi (10 Kg/cm

2

)

Momentary maximum

200 psi (14 Kg/cm

2

)

operating pressure

Temperature

32–104°F (0–40°C) (Liquid should not freeze.)

Liquid viscosity

1 to 50 cps

Output

Open collector (Collector capacity: 30V, 30mA)

Power requirement

4.5 to 25VDC (20mA Max.)*

Green LED lights for each pulse output. Red LED on when the power is ON.

NOTES: 1. Use flow checker only for clear liquids.

2. Pressure loss is 0.5 Kg/cm

2

(at maximum flow rate using water).

*

+ 5V Power Supply provided on board PZi8 Models.

LIQUID-END MATERIALS

PART

MODEL

MODEL

NAME

FC -1P -

ᔤ

FC -1N -

ᔤ

Body

Ryton*

Noryl**

Ball Check

Ceramic

Ceramic

Ball Guide/Joint

PVC

PVC

Valve Seat/O-Ring

EPDM

Fluororubber

* Ryton: PPS — Polyphenylene-sulfide (for general chemicals)

** Noryl: PPO — Polyphenylene-oxide (for sodium hypochlorite)

3-3/8'' (85)

2-3/8'' (60)

2

-5

/8

''

(6

6

)

LED: RED

2'' (50)

2

LED: GREEN

2

''

(4

8

)

1-1/2'' (39)

6

''

(1

4

9

)

The Model FC-1 Flow Checker output provides

vital information for water treatment programs

requiring feed verification to manage chemistry

and monitor drum inventory.

Model FC-1 FLOW CHECKER

MATERIAL SELECTION CHART

PUMPING LIQUID

CONCENTRATION

RECOMMENDED

(in alphabetical order)

TYPE

Acetic acid

50%

VFC/FFC

Acetic acid

concentrated 24°C

FTC

Aluminum sulfate

—

VEC

Amine*

—

SS

Aqueous ammonia

—

VEC

Calcium/Sodium

hypochlorite

12%

CL /AR

Caustic soda

—

VEC

Ferric/Ferrous chloride

—

VFC

Ferric/Ferrous sulfate

—

VFC

Hydrochloric acid

10% to conc.

VFC

Hydrogen peroxide

30%

VFC

Nitric acid

10%

VFC

Nitric acid

30% to conc.

FTC

Phosphoric acid

10% to conc.

FTC

Poly-aluminum

chloride (PAC)

—

VEC

Potassium

permanganate

—

VEC

Sulfuric acid

to 40%

VFC/FFC

Sulfuric acid

concentrated

FTC

*Boiler compounds with small amounts of Amine – FEC

CAUTION – ALL MODELS

• Ambient temperature: 32 to 104°F (0 to 40°C)

Pumped liquids:

Temperature: 32 to 104°F (0 to 40°C),

Viscosity: 100 CPS max. except as noted

• This pump is designed for outdoor use. Avoid

installing pump in a location where service life

could be shortened (i.e., where it is exposed to

direct sunlight or driving rain).

• This pump cannot pump liquids containing a slurry.

• A relief valve should be installed on the discharge

side, if the pump does not have a built-in relief

valve and the discharge piping has a shutoff valve.

INCLUDED WITH

EACH PUMP:

Foot Valve Strainer*

Back Pressure /Check Valve

Injector with Quill*

Suction, Discharge and

Air Release Tubing*

Power Cord with 3-Prong Plug

Signal Cable with Multi-Pin Connectors

(one with PZi4 & two with PZi8 & PZiG models)

*except some PZiG models (see page 4)

Foot Valve

Strainer

Back Pressure

Injector

(shown with

PZi8 type

pump)

T

R

IM

5

/8

"

O

FF

O

F

T

H

IS

S

ID

E

T

O

C

LE

A

R

H

O

LE

D

R

IL

L

5