Pump Solutions Group Neptune Series 6000 dia-PUMP MODELS 6100 thru 6250 User Manual

Page 8

8

1.0.8 Fill gearbox and pump by pouring the hydraulic fluid (drive lubricant) supplied through the fill

opening at the rear of the pump. Pour fluid in slowly until it covers the worm gear. The control

knob should be in the zero position during the filling.

PLEASE NOTE

: TO VENT THE AIR, REMOVE VENT PLUG LOCATED ON TOP OF THE OIL HEAD

(# 54 on Parts Drawing).

Allow 30 minutes for hydraulic fluid to make its way into pump chamber and then recheck fluid

level.

The hydraulic fluid supplied by Neptune is EP SAE 90.

Common sources for hydraulic fluid are:

Shell Oil

Omala #220

Mobil Oil

Mobil Gear #629

Sun Oil

Sun Oil #220

Texaco

Meropa #220

2.0

SUCTION PIPING

2.0.1 The suction piping to the pump must be absolutely airtight and one size larger than suction

inlet size of the pump. It is suggested that the suction piping be tested with low air pressure

and a soap solution to assure that no leaks exist. Limit the total length of the suction line to 3-4

feet for suction lift or 6-7 feet for flooded suction. Minimize bends, elbows, or other restrictions.

2.0.2 NEPTUNE RECOMMENDS THAT THE “dia-PUMP” BE OPERATED WITH A FLOODED

SUCTION, AS THIS WILL FACILITATE START UP AND INCREASE THE SERVICE LIFE OF

THE PUMP.

2.0.3 It is highly recommended that all solution tanks be furnished with a low level cut off switch or

low-level alarm and cut off switch to prevent the pump from running dry. OPERATION

AGAINST A DRY SYSTEM WILL CAUSE DAMAGE TO THE PUMP DIAPHRAGM AND

REDUCE THE OPERATING LIFE OF THE PUMP.

3.0 DISCHARGE PIPING

3.0.1 It is recommended that the “dia-Pump” operate against a minimum discharge pressure of 50

psig.

3.0.2 All Neptune Series 6000 “dia-Pumps” are supplied with an internally pre-set relief valve. This

relief valve is set above the actual rated discharge pressure of the pump and is designed to

protect the pump should a discharge pressure’ beyond the rated limit of the pump occur.

3.0.3 To protect the piping system, it is recommended that an external relief valve as manufactured by

Neptune Chemical Pump Company, or equal, be placed in the discharge line of the pump.

3.0.4 Discharge piping should equal discharge port size.

4.0 ADJUSTMENT OF INTERNAL RELIEF VALVE

4.0.1 All Neptune Series 6000 “dia-Pumps” are supplied with an internally pre-set relief valve. The

internal relief valve is set as follows:

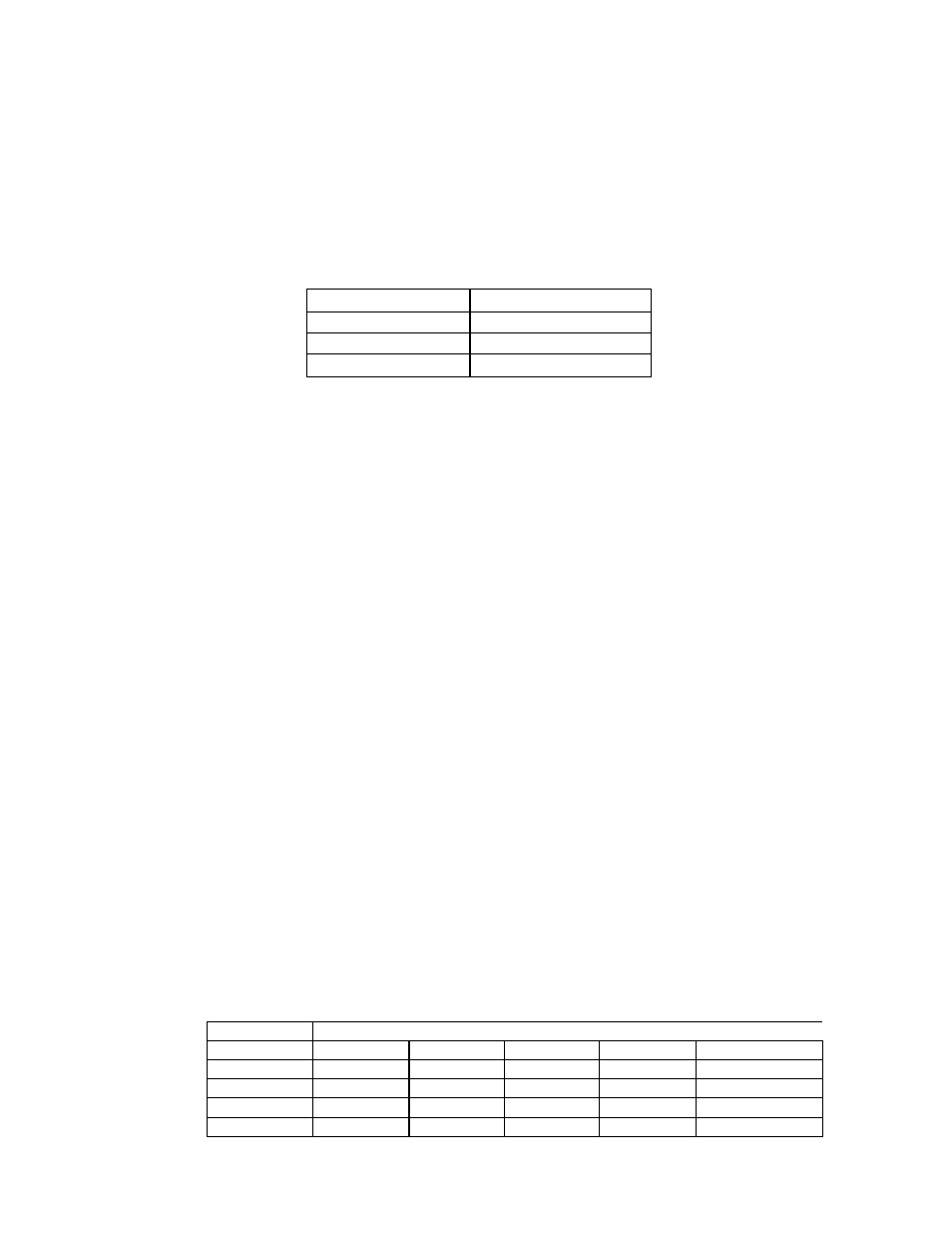

APROXIMATE INTERNAL RELIEF VALVE SETTING (PSI)

Model

1/2 HP

3/4 H/P

1 H/P

1-1/2 HP

2 HP

6100

1500

2500

3000

4000

4500

6150

1500

2500

3000

3500

4000

6250

600

1200

2000

2300

2500