Pump Solutions Group Neptune Series 6000 dia-PUMP MODELS 6100 thru 6250 User Manual

Page 21

21

SECTION IX

DOUBLE DIAPHRAGM OPTION

Special Instructions for Series 6000 “dia-Pumps” with Double Diaphragm

The instructions below are for Neptune’s optional Double Diaphragm Kit.

Use of a double diaphragm allows diaphragms to be

monitored and provides an early warning upon failure of

either diaphragm allowing repairs to be made before

process fluid can mix with the pump’s hydraulic fluid.

Neptune’s double diaphragm is a kit, which may be

retrofitted to any pump currently in service or may be

installed on a new pump at the factory.

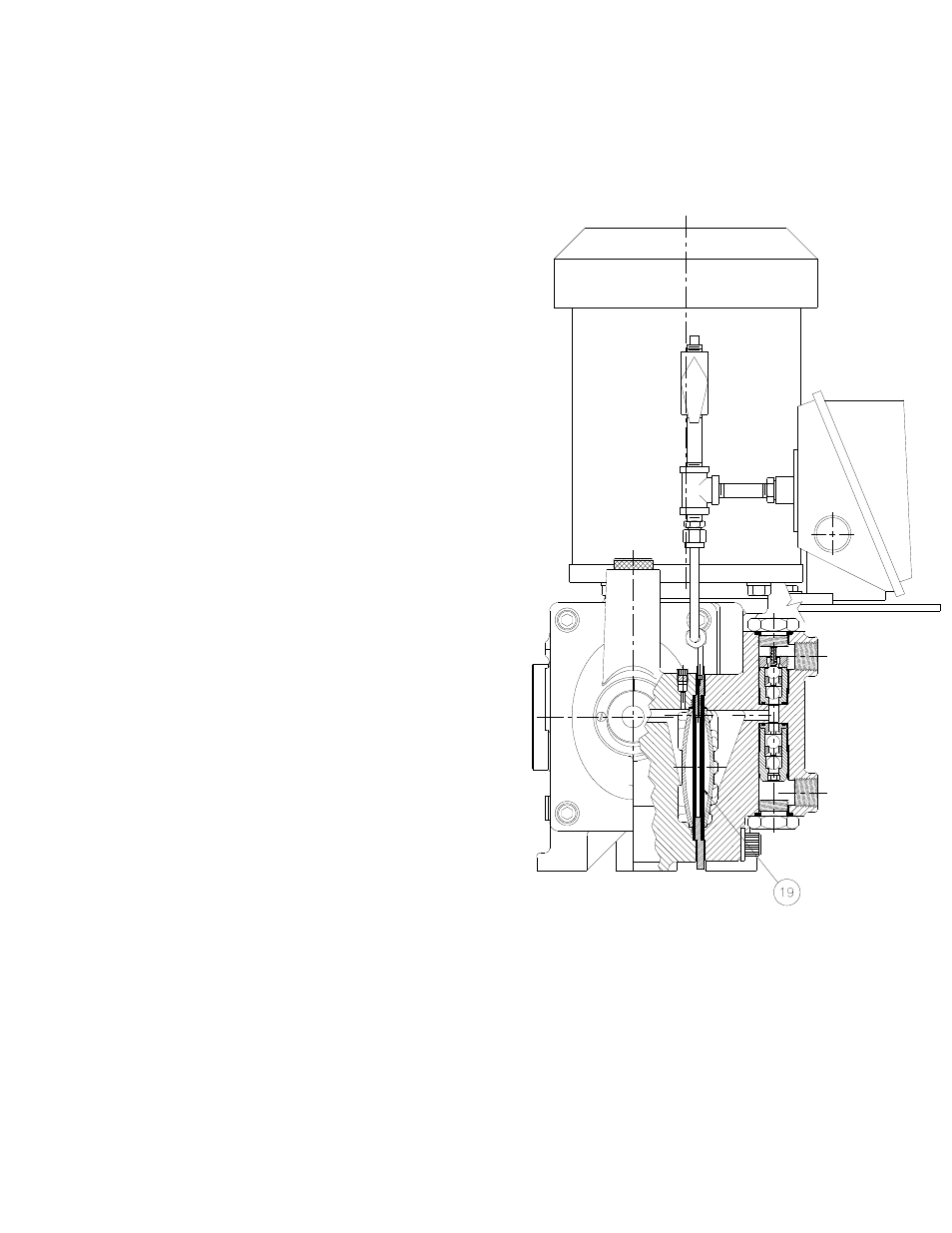

Figure 4, illustrates a Double Diaphragm Assembly.

An intermediate plate is located between the oil and

liquid heads with one diaphragm on each side of the

intermediate plate. The Intermediate Plate is

connected to a rupture alarm or pressure switch via a

capillary system. The area between the diaphragms

is evacuated. Rupture in either diaphragm produces

an increase in volume and, therefore, a pressure

increase, which can be sensed by a pressure switch

for alarm purposes.

DISASSEMBLY OF INTERMEDIATE PLATE

11.0.0 Shut pump off and disconnect suction and

discharge piping. Remove drain plug and

drain hydraulic fluid from the gearbox.

11.0.1 Remove 8 Screws and remove the liquid

head assembly. Some hydraulic oil and

process fluid will spill out when the head is

removed.

11.0.2 The intermediate plate, which is between the

pump heads can be removed easily.

11.0.3 Remove the rupture alarm (pressure switch)

and clean the capillary system.

11.0.4 Replace one or both diaphragms if needed.

11.0.5 To reassemble reverse above procedure. Be

certain that parts align properly.

FIGURE 4

VACUUM AIR FROM INTERMEDIATE SPACE

11.0.6 Open valve Item No. 5 (Figure 5).

11.0.7 To remove air, attach the vacuum pump with a hose connection Item No. 6 to the valve

Item No. 5 (Figure 5). The intermediate space is evacuated to 3 psig for normal operating

conditions.

11.0.8 Close valve Item No. 5 (Figure 5).